A method for improving welding performance of 5g communication module

A communication module and welding performance technology, applied in welding equipment, welding medium, welding/cutting medium/material, etc., can solve problems such as false welding, achieve bright and full solder joints, increase inner temperature, and good moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

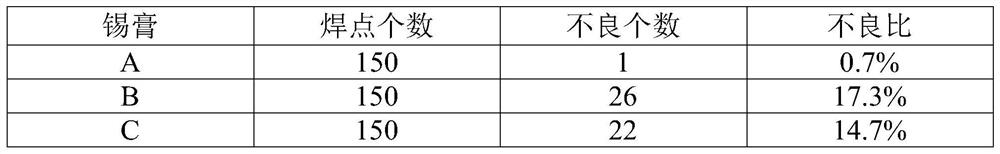

Embodiment 1

[0021] A material is added in the preparation process of the solder paste, and the obtained solder paste is uniformly mixed with the tin powder to prepare the solder paste;

[0022] The operation steps of the method for improving the welding performance of a 5G communication module are as follows:

[0023] Step 1: heating and stirring the quantitative components of rosin, solvent, thixotropic agent and modification additive to obtain a mixture;

[0024] Step 2: Add the active agent of quantitative components to the mixture, heat and stir evenly, and then cool to room temperature to become a flux paste;

[0025] Step 3: Put the flux paste and tin powder into the solder paste mixer, heat and stir evenly to get the solder paste.

[0026] As a technical optimization scheme of the present invention, it is composed of the following raw materials by weight: 11% of solder paste, 89% of tin powder, wherein the mass percentage of the solder paste contains 35%-40% rosin, 40%-45% % of s...

Embodiment 2

[0033] Based on the method for improving the welding performance of a 5G communication module provided by the first embodiment of the present invention, the method for improving the welding performance of a 5G communication module provided by the second embodiment of the present invention is different in that the solder paste includes the following raw materials by mass percentage: Soldering paste 11% (wherein the soldering paste includes the following mass percentage materials, 40% rosin, 43% diethylene glycol dibutyl ether and ethylene glycol butyl methyl ether, 4% hydrogenated castor oil, 9% hexane Diacid and stearic acid, 2% benzotriazole, 1% OP-10 and 1% terminal azide polyazide glycidyl ether), tin powder 89%, rosin in the solder paste It accounts for 40% of the solder paste, which can effectively improve the poor soldering performance caused by the temperature in the shield, especially the false soldering problem of the module.

Embodiment 3

[0035] Based on the method for improving the welding performance of a 5G communication module provided by the first embodiment of the present invention, the method for improving the welding performance of a 5G communication module provided by the third embodiment of the present invention is different in that: the solder paste includes the following raw materials by mass percentage: Soldering paste 11% (wherein the soldering paste includes the following mass percentage materials, 41% rosin, 43% diethylene glycol dibutyl ether and ethylene glycol butyl methyl ether, 4% hydrogenated castor oil, 9% hexane Diacid and stearic acid, 2% of benzotriazole, 1% of OP-10), 89% of tin powder, using the above scheme to prepare the modified material in the solder paste can release heat during the welding process, improve the module Temperature inside the middle shield.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com