Asphalt additive and asphalt mixture containing same

A technology of asphalt mixture and asphalt additives, which can increase the thickness, improve the ability to resist water damage, and increase the gripping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

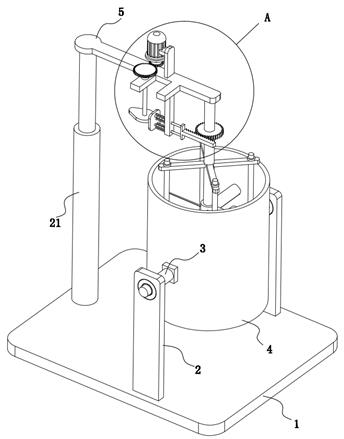

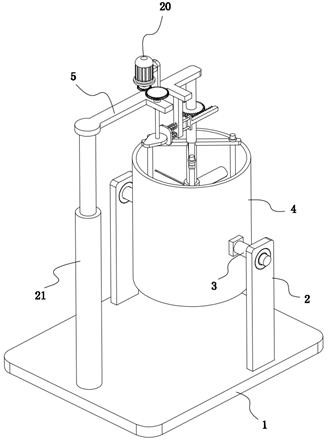

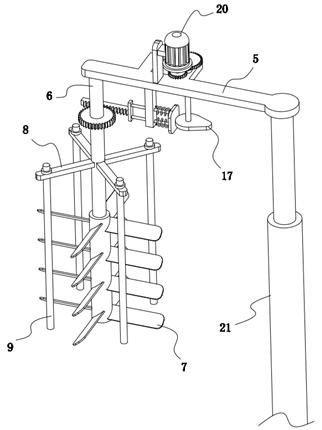

[0020] The present invention also provides a preparation device for asphalt mixture, comprising a base 1, two vertical boards 2 correspondingly arranged are fixedly mounted on the upper surface of the base 1, and a rotating shaft 3 is rotatably mounted on the two vertical boards 2, And the two rotating shafts 3 are coaxially arranged, any one of the rotating shafts 3 is connected with a rotating drive module, a vertical barrel body 4 is fixed between the two rotating shafts 3, a top plate 5 is arranged above the barrel body 4, and the top plate 5 The upper part is rotatably equipped with a vertical shaft 6 coaxially arranged with the barrel body 4, and the bottom end of the vertical shaft 6 is fixedly connected with a stirring shaft 7 coaxially arranged therewith, and the surface of the vertical shaft 6 above the stirring shaft 7 is fixed along the circumferential direction Several crossbars 8 evenly distributed are installed, and an electric heating rod 9 parallel to the verti...

Embodiment 2

[0029] Example 3

[0030] An asphalt mixture, including matrix raw materials and asphalt additives, the formula of the raw materials by weight is as follows: 4 parts of matrix raw materials, 0.7 parts of asphalt additives.

[0031] The matrix raw materials are composed of asphalt, coarse aggregate, fine aggregate, mineral powder, polymer, and wood cellulose.

[0032] The mineral powder is limestone mineral powder. Limestone powder plays a filling role in asphalt mixture, the purpose is to reduce the void of asphalt concrete, sometimes called filler. Mineral powder and asphalt together form asphalt mortar, which improves the strength and stability of asphalt concrete. The amount of slag powder content is often expressed by the powder-oil ratio. The high-temperature rutting resistance of asphalt concrete is usually strong when the powder-oil ratio is large, and the small powder-oil ratio is beneficial to the low-temperature crack resistance of concrete.

[0033] The drive mod...

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com