Heating and heat preservation type resin heating tank system

A technology for heating, heat preservation and tank heating, which is applied in the direction of tank trucks, large containers, containers, etc. It can solve the problems of uneven heating, difficult cleaning of residual resin sticking to the barrel wall, heat dissipation, etc., and achieve the effect of avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

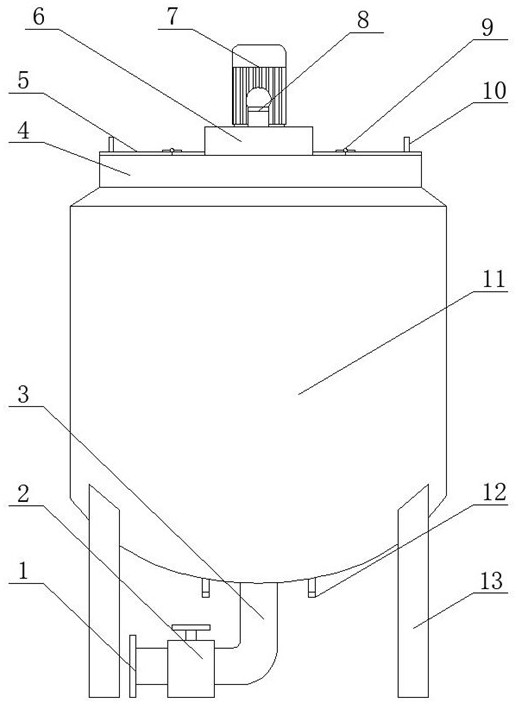

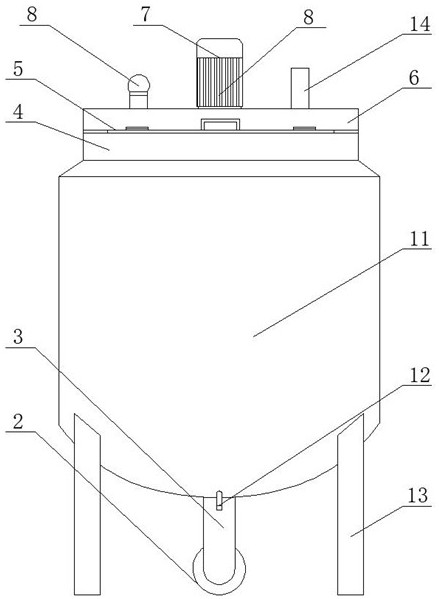

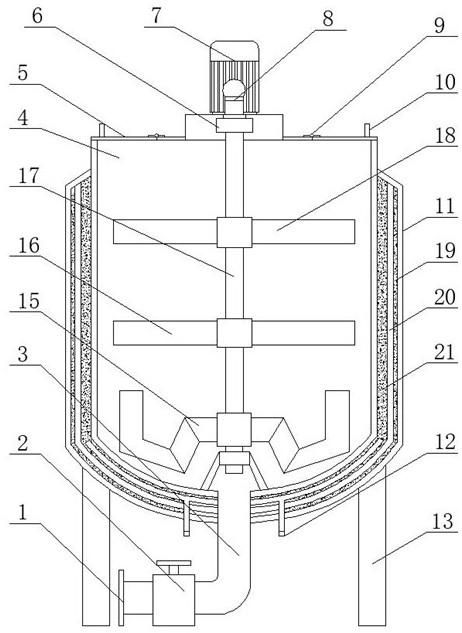

[0029] see Figure 1-4 , the present invention provides a technical solution: a heating and thermal insulation resin heating tank system, including a tank body 4 and an intermediate layer 20, an intermediate layer 20 is provided on the periphery of the tank body 4, and a tank body 4 and the intermediate layer 20 are provided between The heat transfer oil 21, the lower end of the middle layer 20 is provided with an electric heating pipe 12, and the lower end of the electric heating pipe 12 penetrates the outer layer 11, the insulation cotton 19 and the middle layer 20, so that it is convenient to energize the electric heating pipe 12 from the outside of the equipment, and the electric heating pipe 12 The upper end of the heat-conducting oil 21 is located in the heat-conducting oil 21, so that the heated electric heating pipe 12 can heat the heat-conducting oil 21, and the electric heating pipe 12 can heat the heat-conducting oil 21 inside, so that the heat-conducting oil 21 can ...

Embodiment 2

[0031] see Figure 1-4, the present invention provides a technical solution: a heating and thermal insulation resin heating tank system, a thermal insulation cotton 19 is arranged between the outer layer 11 and the middle layer 20, a support leg 13 is arranged at the lower end of the outer wall of the outer layer 11, and the outer layer 11 A total of four support legs 13 are arranged at the lower end of the outer wall, which can make the device more stable when placed on the ground, and also more stable when stirring inside the equipment. The four support legs 13 are all metal structures. The material can make the four support legs 13 more durable, and the four support legs 13 are all fixed with the outer wall of the outer layer 11 by welding, and the welding method can make the four support legs 13 better fixed with the outer layer 11 , there will be no breakage of the connection. The middle part of the lower end of the tank body 4 is provided with a discharge pipe 3, and the...

Embodiment 3

[0033] see Figure 1-4 , the present invention provides a technical solution: a heating and heat preservation resin heating tank system, the left end of the discharge valve 2 is provided with a connecting flange 1, and the connecting flange 1 can be connected with other pipes through bolts, so that the The heated resin is discharged into other pipelines, so as to facilitate the next processing of the heated resin. The rear side of the inner wall of the tank body 4 is provided with a floating ball 22, and the floating ball 22 can move up and down on the inner wall of the tank body 4, so that The liquid level of the internal resin can be observed through the floating ball 22 to control the amount of resin added. The inside of the tank body 4 is vertically provided with a drive shaft 17, and the drive shaft 17 is sequentially provided with lower stirring blades 15, The middle layer stirring blade 16 and the upper layer stirring blade 18, the lower end of the transmission shaft 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com