Tool and method for pressing dustproof oil seal in blind hole of steering gear

A dust-proof oil and steering gear technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of dust-proof effect failure, dust-proof oil seal rebound, and improper press-fitting, so that it is not easy to deviate and easy to operate , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the orientation terms such as left, middle, right, up, and down in the examples of the present invention are only relative concepts or refer to the normal use state of the product, and should not be considered as restrictive .

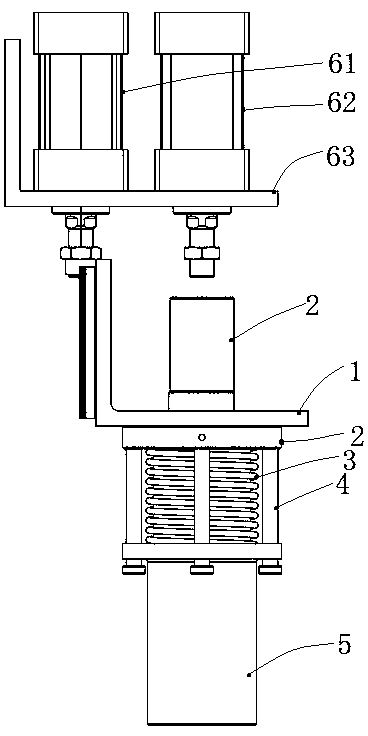

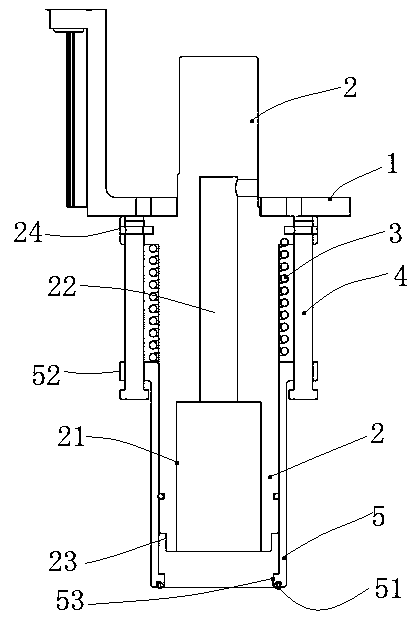

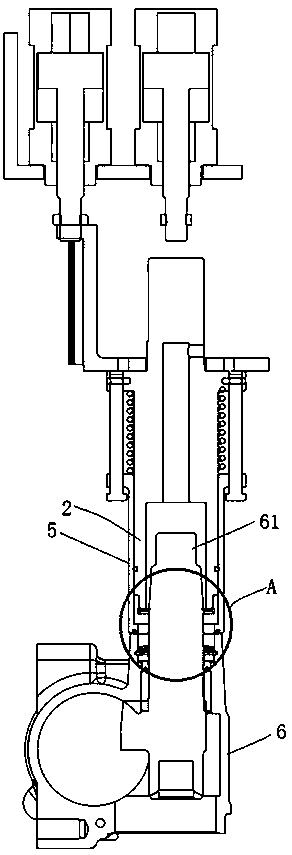

[0026] A tool for press-fitting a dust-proof oil seal into a blind hole of a steering gear, combined with figure 1 and figure 2 As shown, it includes a vertically arranged finale shaft 2, a connecting plate 1 is looped on the upper end of the finale shaft 2, and a sealing sliding sleeve 5 is looped and slidably fitted on the lower end of the finalizing shaft 2, and the sealing sliding sleeve 5 and the finale shaft 2 are sealed, and the lower end port of the sealing sliding sleeve 5 is provided with a sealing device 51; there is a compression spring 3 in the middle loop of the finale shaft 2, and the two ends of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com