Coding machine based on garment production

A coding machine and clothing technology, which is applied in the field of coding machines, can solve the problems of poor coding effect, inability to store and fix, uneven printing surface of clothes, and achieve good coding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

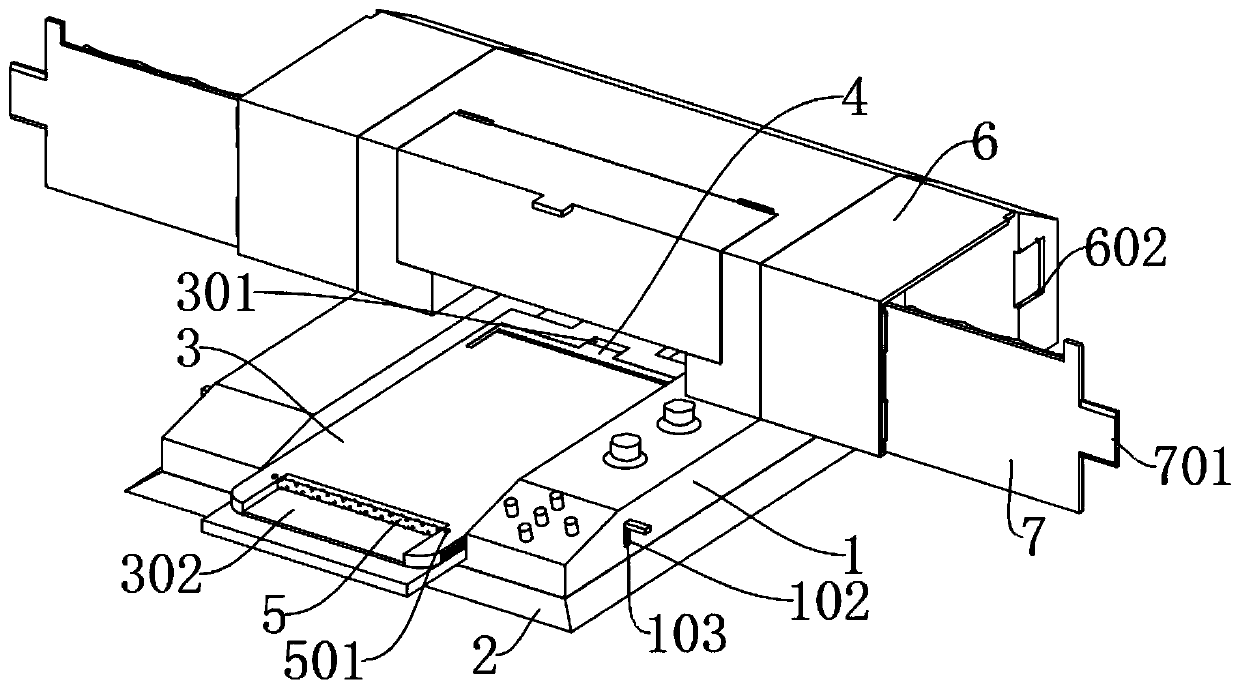

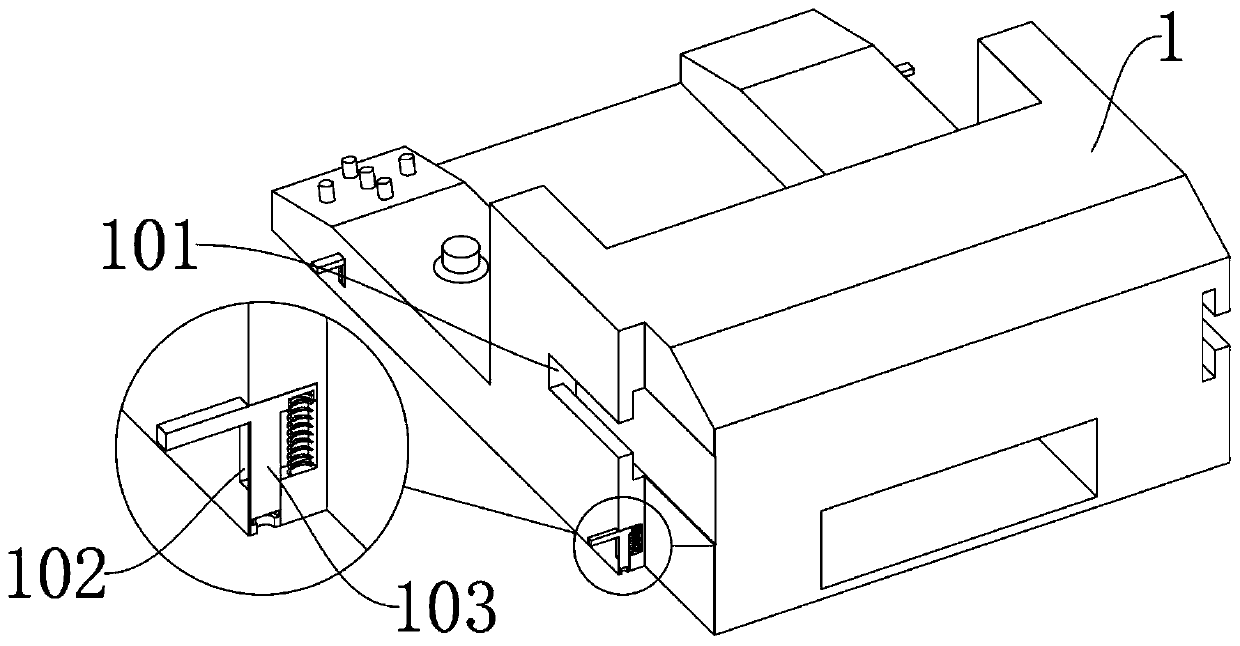

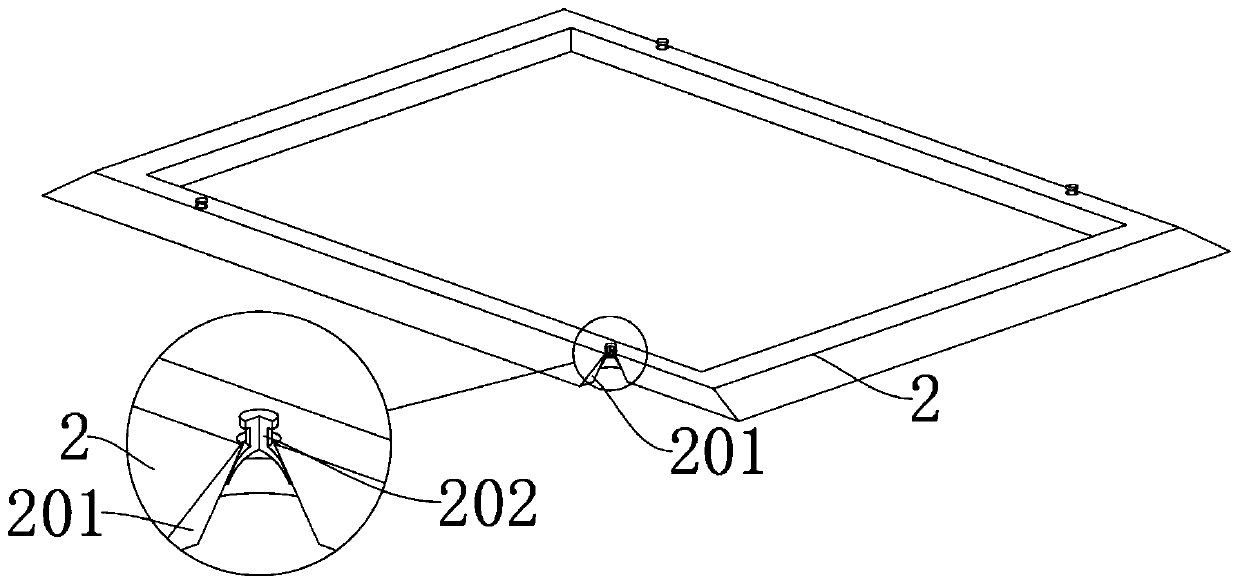

[0030] as attached figure 1 To attach Figure 8 Shown:

[0031] The present invention provides a coding machine based on garment production, including: a main body 1, a bottom part 2, a moving plate 3, an insert part 4, a rotating part 5, a storage bin 6 and a flipping plate 7; the coding machine of the main body 1 The body, and the middle position of the front end of the main body 1 is provided with a groove, and the moving groove 102 is used to make the moving part 103 move inside it, so that the moving part 103 can be connected with the inner part 202, so as to effectively control the inner part. part 202, the spring at the bottom of the moving groove 102 is used to support the upward movement, so that after the moving groove 102 is connected with the inner part 202 through the groove, the inner part 202 can be subjected to an upward pulling force, so that the bottom hole 201 is adsorbed on the When placed on the surface, it can be more stable; the top of the bottom part ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap