Single-head flex cable and detection packing machine and packing method thereof

A packaging machine and line detection technology, which is applied in the direction of transportation and packaging, packaging material feeding device, packaging, etc., can solve the complicated operation of single-head wire packaging into the bag, single-head wire handling is easy to leave, single-head wire Low transfer efficiency and other issues, to achieve the effect of easy separation, avoid residue, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

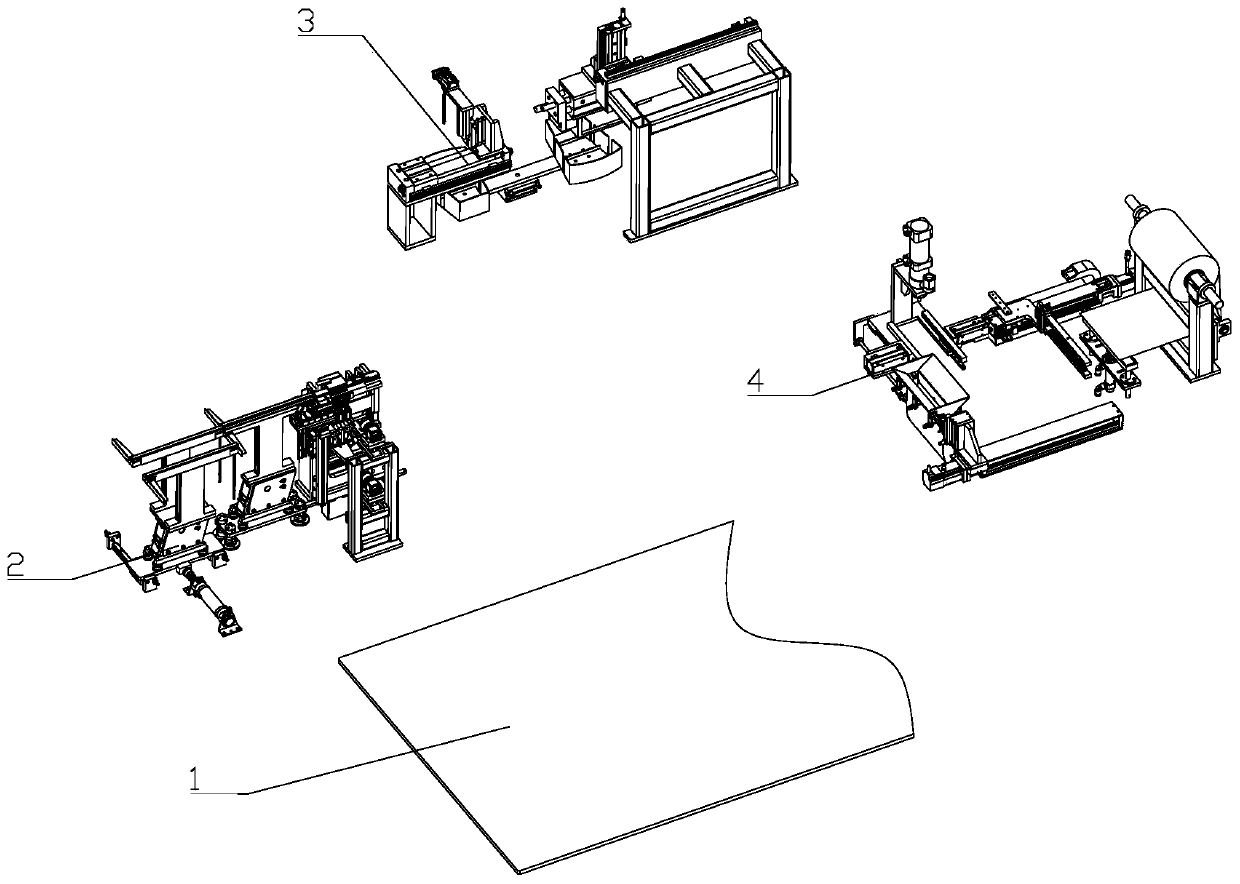

[0030] like figure 1 As shown, a single-head cable detection packaging machine includes a frame 1 and a single-head cable separation device 2 installed on the frame 1, a single-head cable handling device 3 and a single-head cable packaging device 4; along the processing In the direction of proceeding, the single-head cable separation device 2, the single-head cable handling device 3 and the single-head cable packaging device 4 are successively arranged in sequence; the single-head cable separation device 2 is used to separate the single-head The cable is inspected and unqualified products are separated. The single-head cable handling device 3 is used to carry the single-head cable, and the single-head cable packaging device 4 is used to pack the single-head cable into bags.

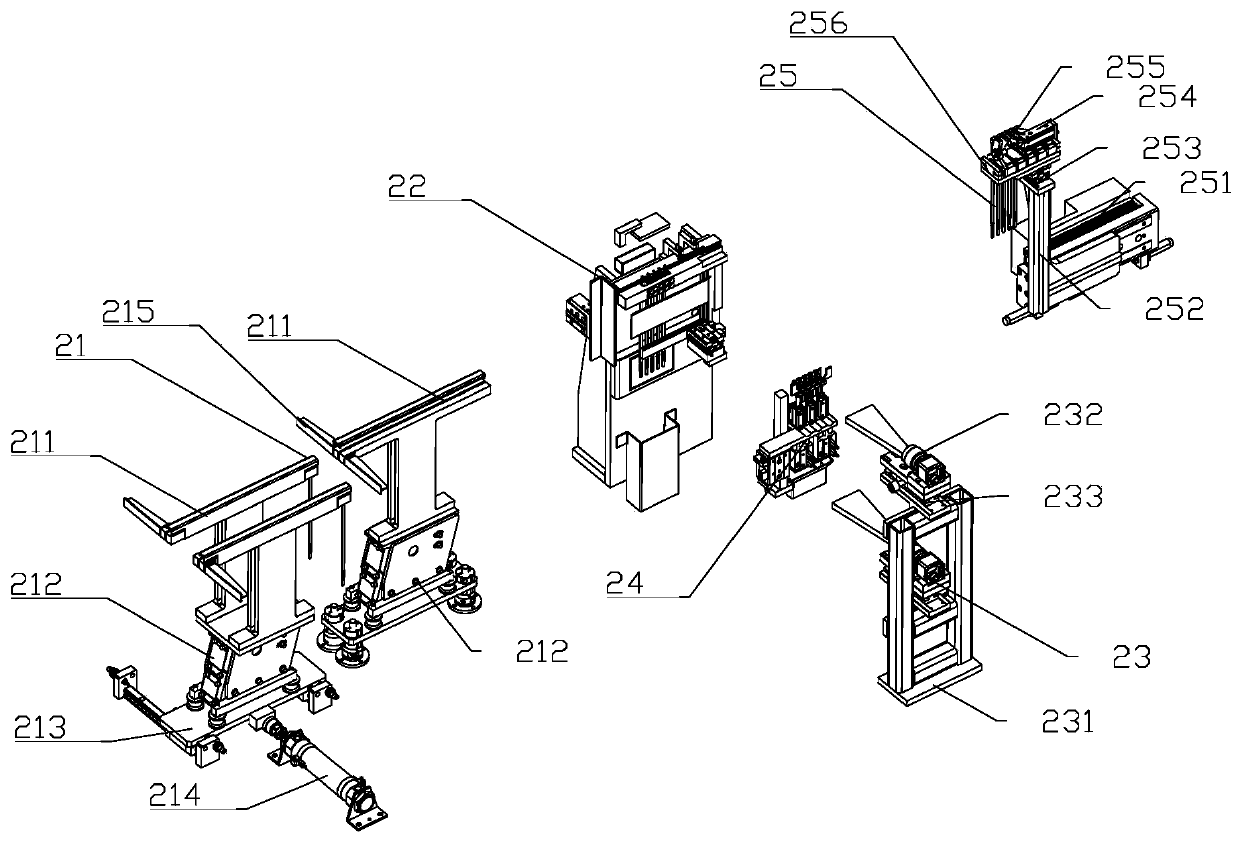

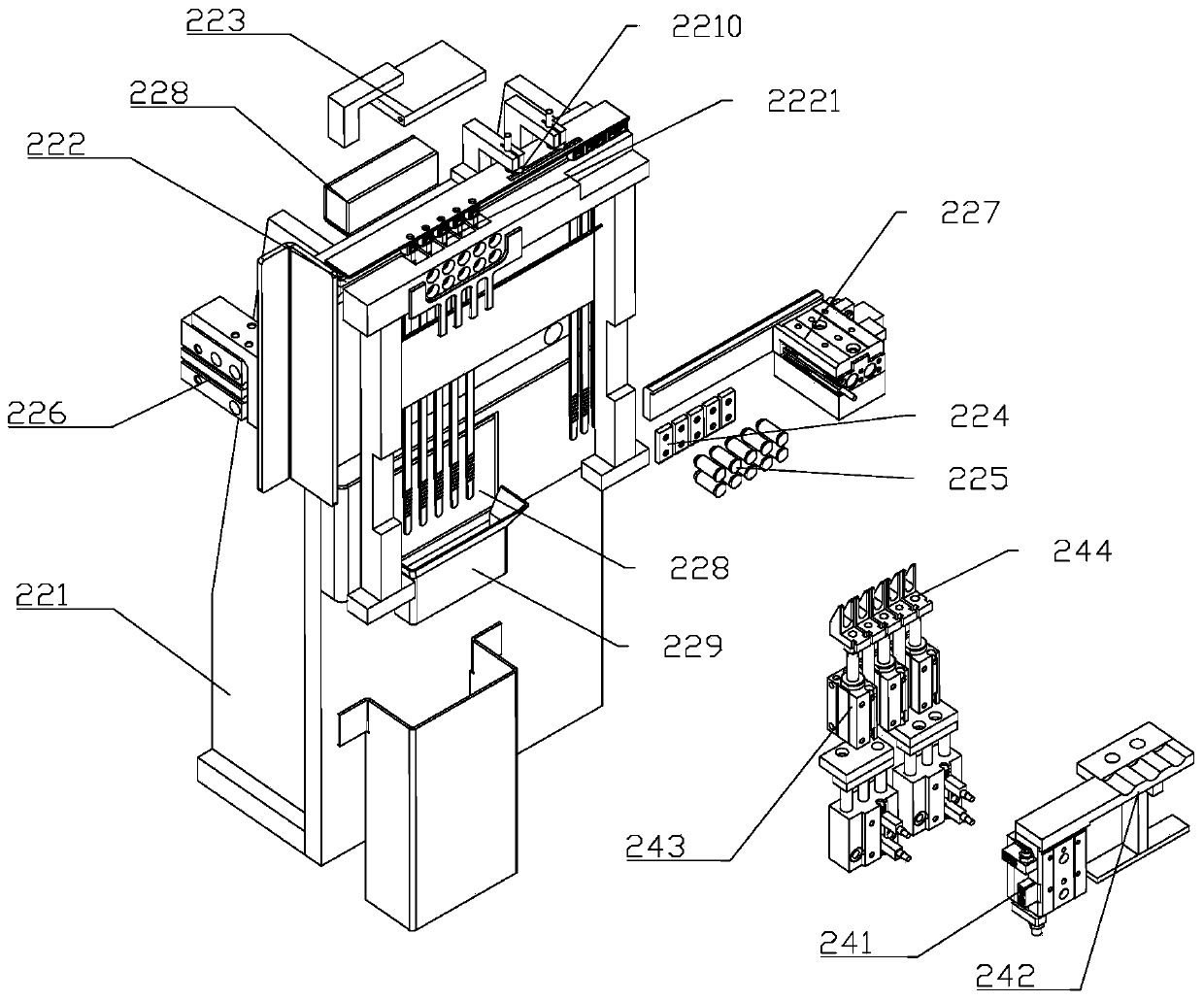

[0031] like figure 2 As shown, the single-head cable separation device 2 includes a vibrating feeding component 21, a material passing component 22, a visual inspection component 23, a separation compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com