A continuous cutting device for the production of paper-plastic bags

A paper-plastic bag and cutting technology, which is used in transportation and packaging, thin material processing, sending objects, etc., can solve the problems of limited cutting efficiency, difficult cutting needs, inability to achieve continuous cutting, etc., so as to improve the cutting efficiency. Efficiency, high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

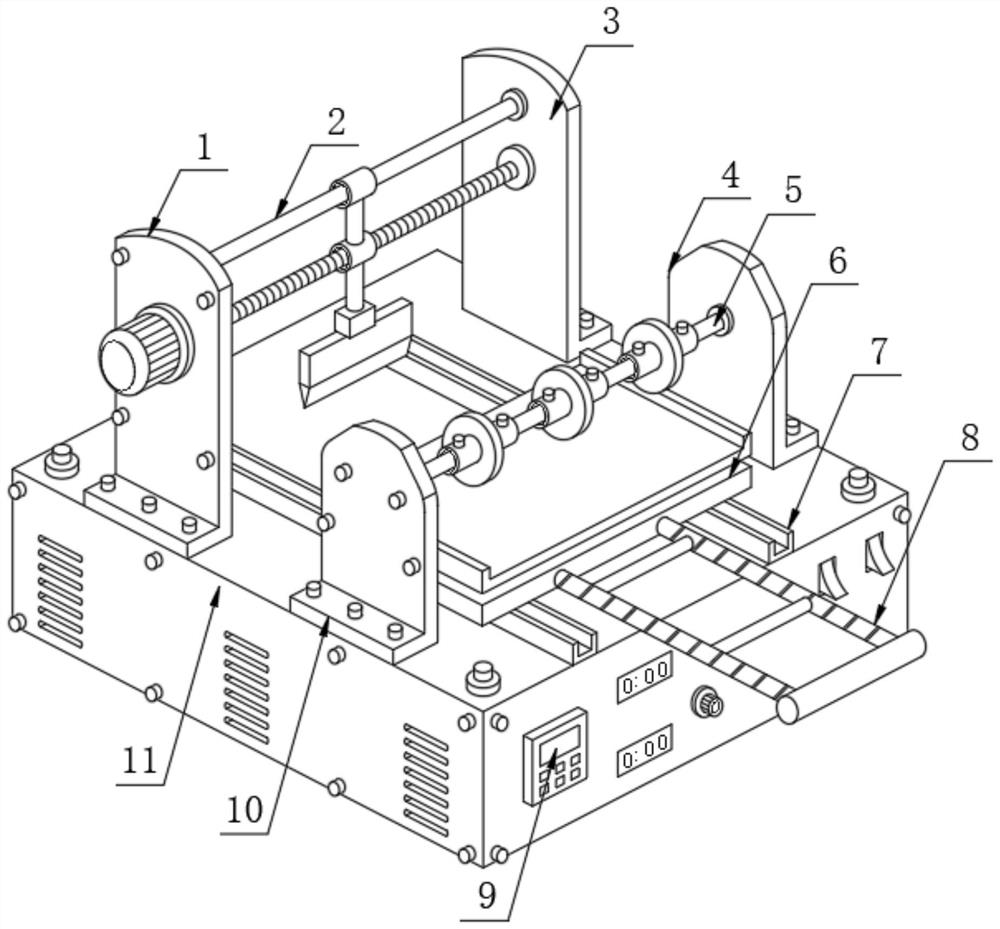

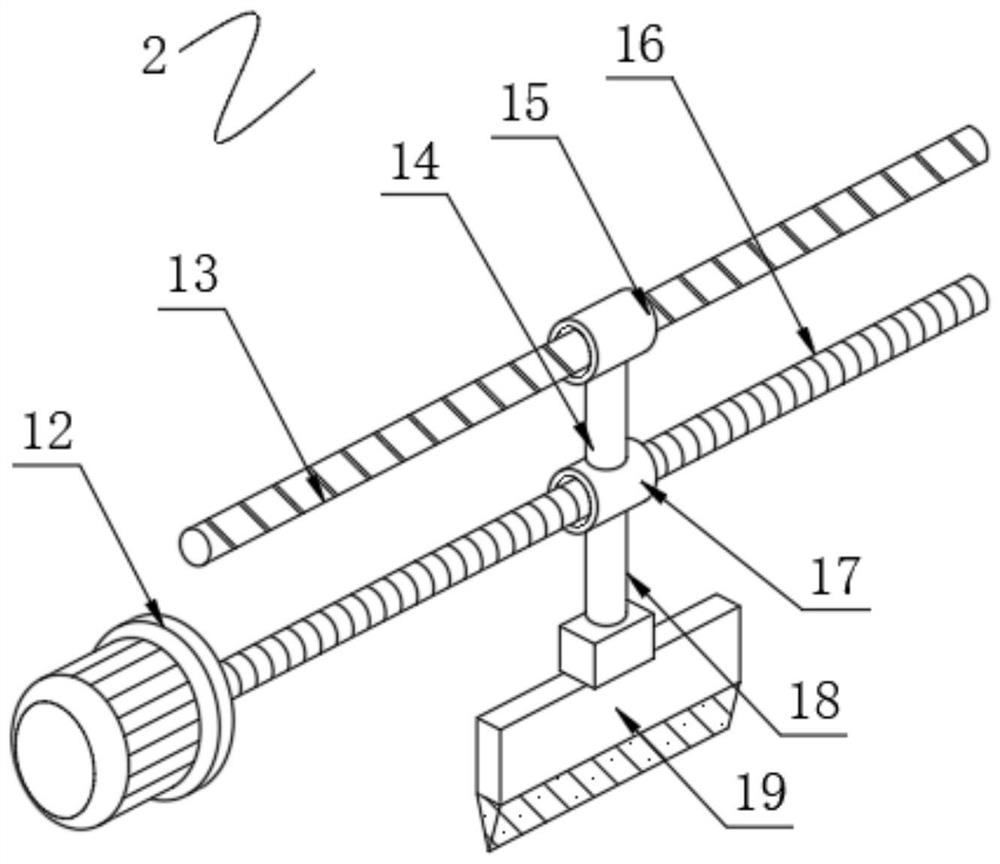

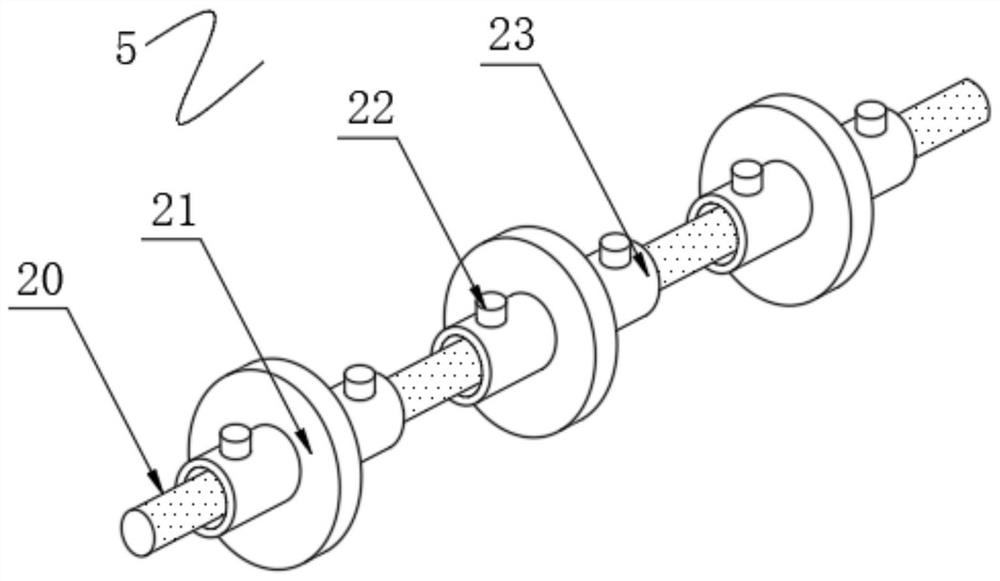

[0023] see Figure 1-5 , in an embodiment of the present invention, a continuous cutting device for producing paper-plastic bags includes a workbench 11, two square slide rails 7 are fixedly attached to the upper surface of the workbench 11, and the upper surface of the workbench 11 is close to the square slide rails 7 The first L-shaped bracket 1 and the second L-shaped bracket 3 are fixedly connected to both sides, the control switch 9 is fixedly connected to the front surface of the workbench 11, and the battery is fixedly connected to the rear surface of the workbench 11, and the control switch 9 DKC-Y110 controller is installed inside, the front side of the first L-shaped bracket 1 and the second L-shaped bracket 3 is provided with the third L-shaped bracket 10 and the fourth L-shaped bracket 4, the first L-shaped bracket 1 and the second L-shaped bracket A first cutting assembly 2 is arranged between the L-shaped brackets 3, and the first cutting assembly 2 includes a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com