Retention wall treatment device and method for chlorine-containing organic matter development

A technology for processing equipment and organic matter, applied in the field of water treatment, can solve the problems of old technology, low removal efficiency, large area occupation, etc., and achieve the effect of powerful function, wide application range, novel and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

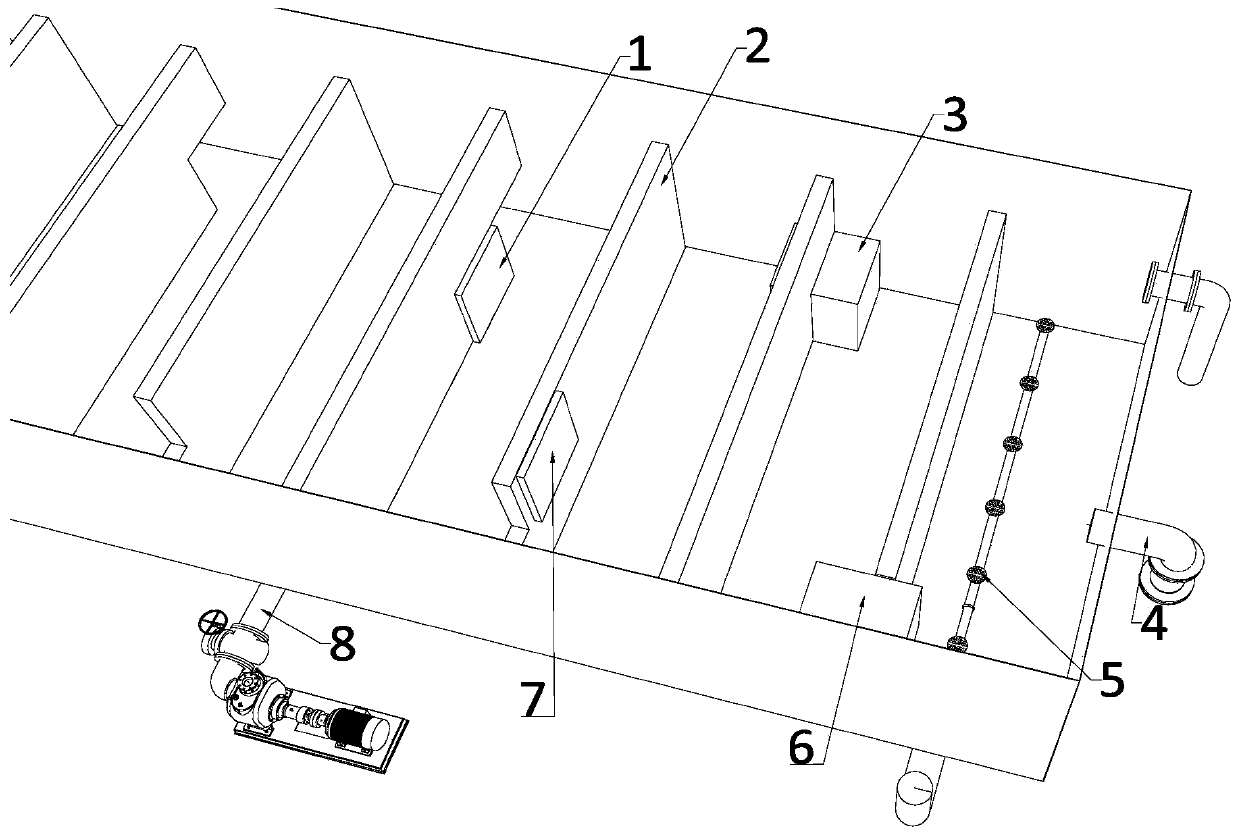

[0029] figure 1 It is a diagram of a retaining wall treatment equipment developed for chlorine-containing organics in the present invention. Including: sewer door 1, circuitous water wall 2, sewer treatment 3, drain pipe 4, exhaust port 5, water treatment 6, upper water door 7, water inlet pipe 8; parallel and equidistant arrangement of multiple heights 3~ 5m of circuitous water wall 2, only one water outlet is set at the end of each circuitous water wall 2, and there is a water outlet at the end of odd numbered circuitous water wall 2, and the sewer gate 1 and sewer treatment 3 are connected to it at intervals; even number of circuitous water walls 2 ends There is a water outlet port on the upper part, and the water gate 7 is connected with the water treatment 6 at intervals; a water inlet pipe 8 is arranged at the bottom of one end of the treatment water tank, and a drainage pipe 4 is arranged at a high position at the other end of the treatment water tank; between the two c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap