Building exterior wall decoration construction process

A technology for building exterior walls and construction technology, applied in building maintenance, construction, building construction, etc., can solve the problems of reduced flatness, colloid can not fill brick joints, and reduced colloid and tile adhesion, etc., to improve the aesthetics. , Improve the stability and reduce the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

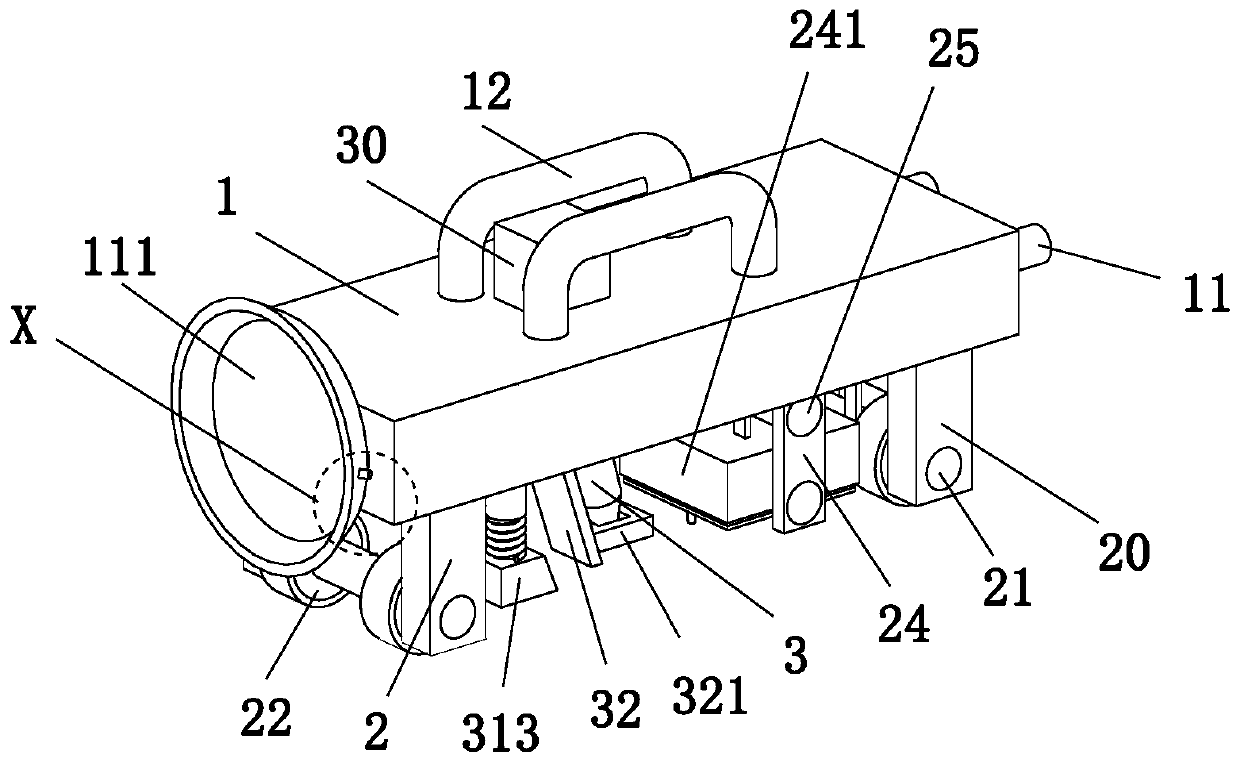

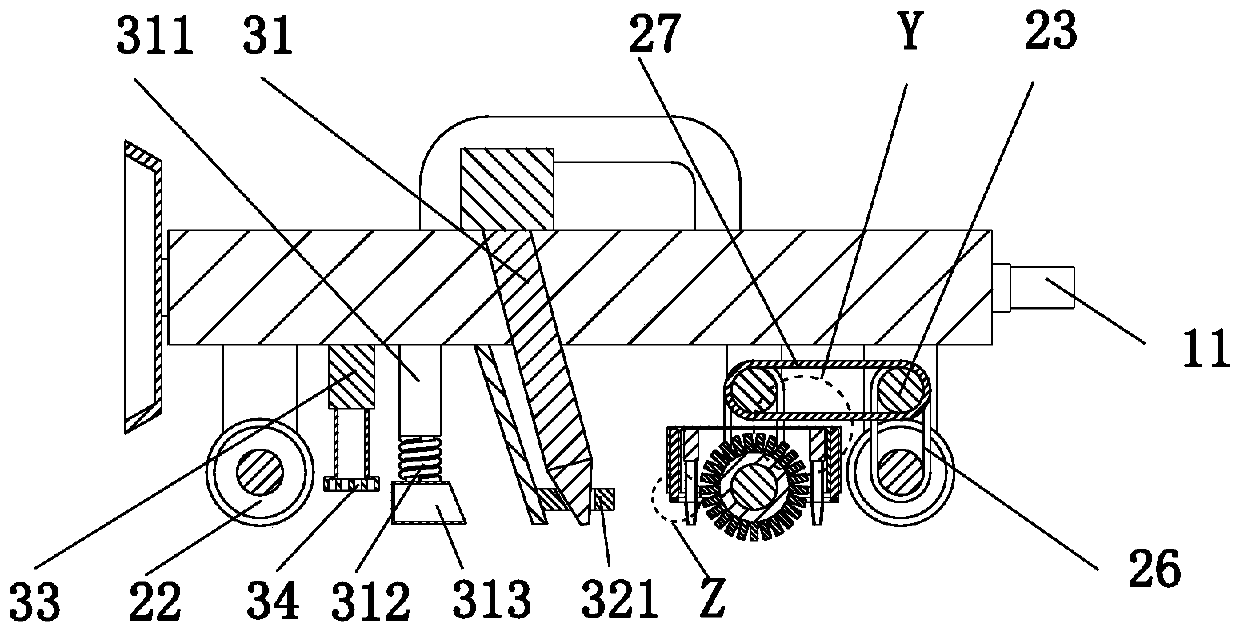

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

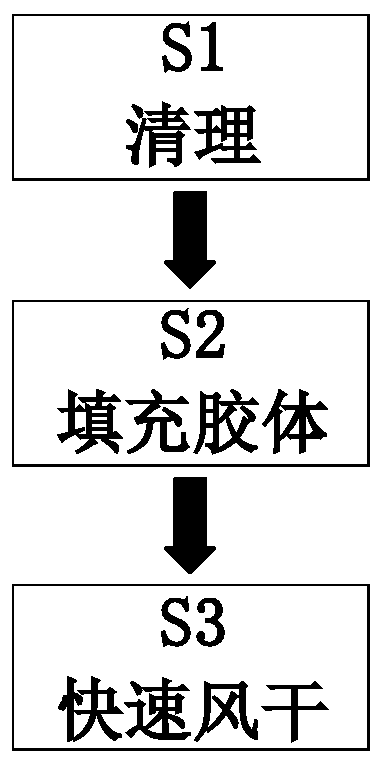

[0033] like Figure 1 to Figure 7 As shown, a building exterior wall decoration construction process, which uses a building exterior wall decoration construction device, the building exterior wall decoration construction device includes a base 1, a cleaning mechanism 2 and a glue filling mechanism 3, using the above-mentioned building exterior wall The specific construction process of the decoration construction device for the decoration construction of the building exterior wall is as follows:

[0034] S1. Cleaning: Manually hold the base 1 and make the roller 22 stick to the wall to move upwards, the roller 22 drives the fixed shaft 21 to rotate, and at the same time drives the No. 1 shaft 23 to rotate synchronously through the No. 1 belt 26, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com