Shield machine shield shell back soil removing device

A shield machine, back soil technology, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of poor ductility and low soil fragmentation efficiency, and achieve the effect of reducing soil adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

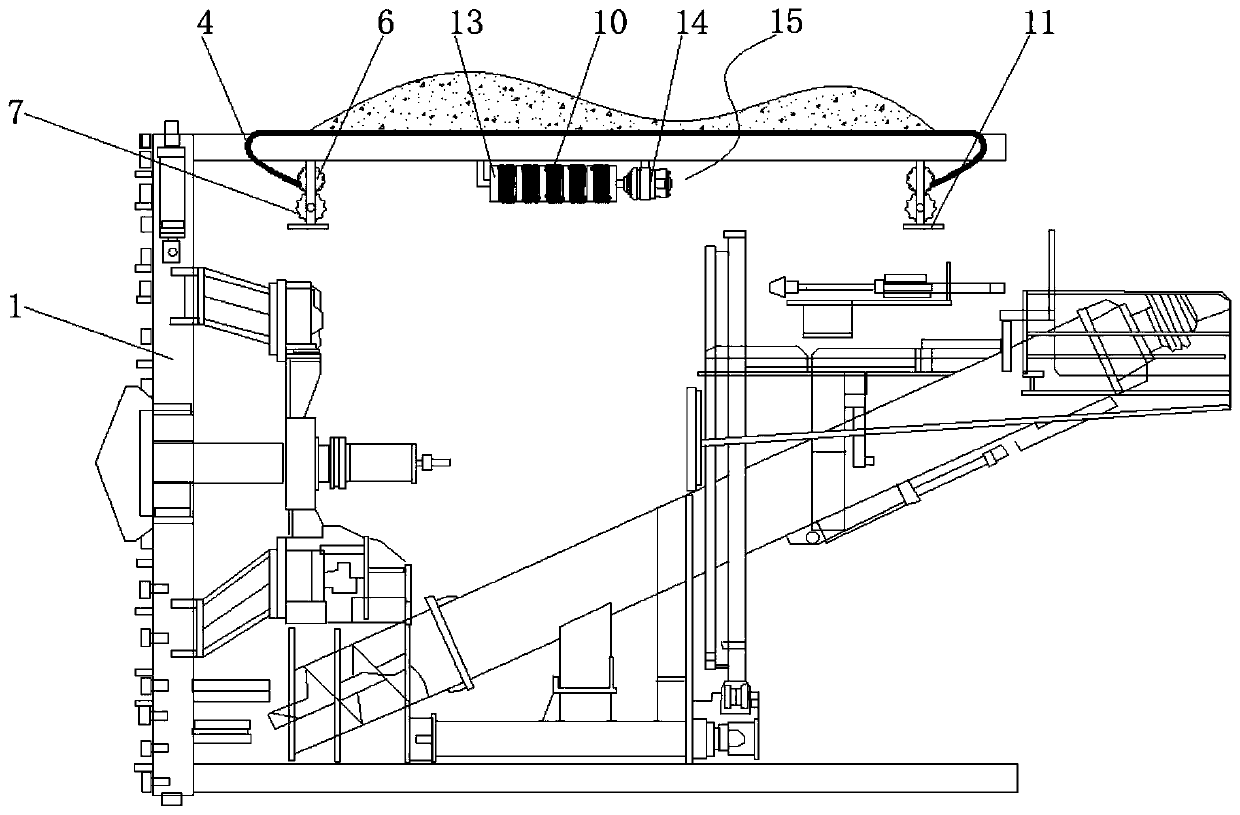

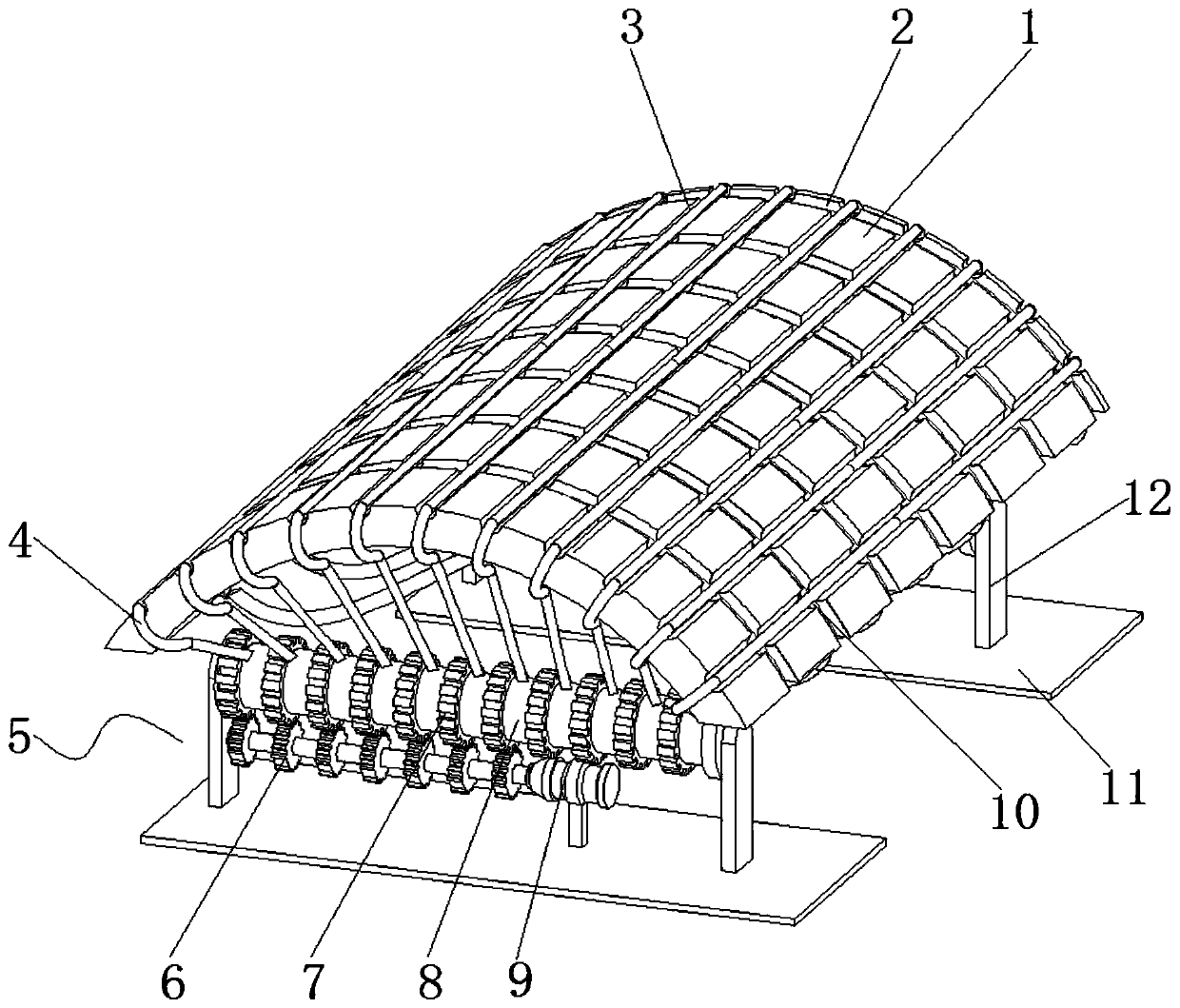

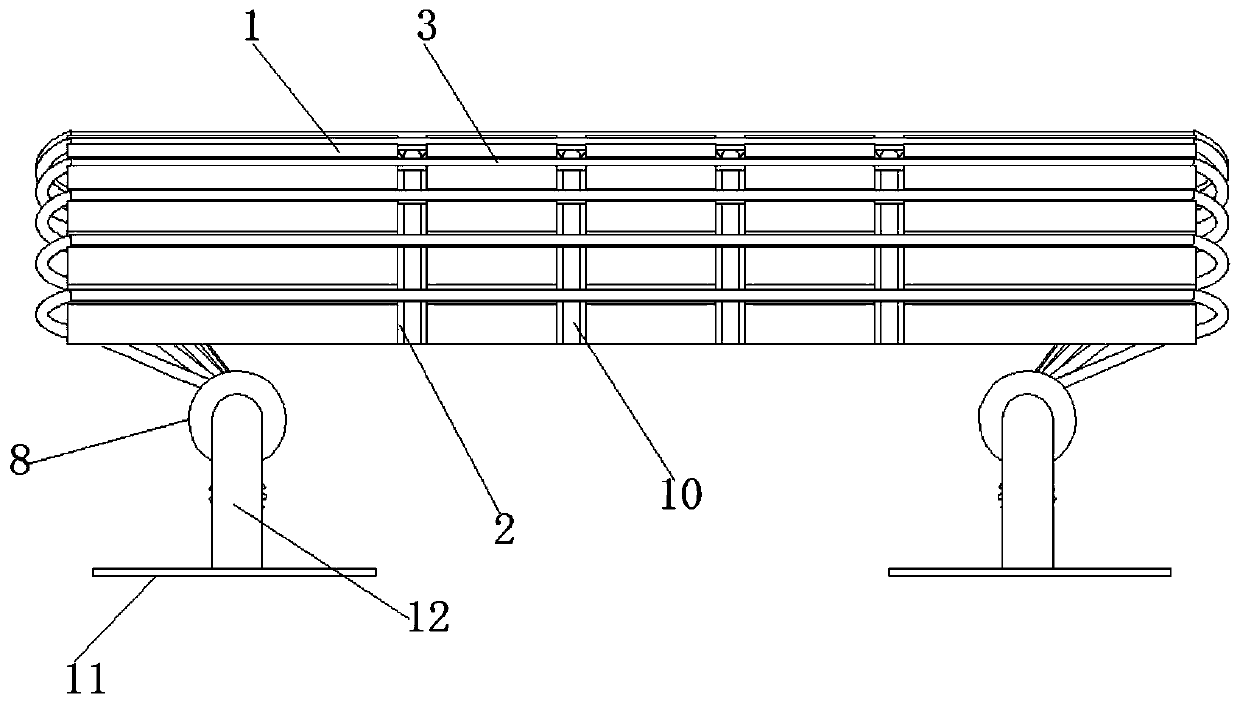

[0021] The embodiment of the present invention provides a device for removing the back soil of the shield shell of the shield machine, such as Figure 1-4 As shown, it is set on the shell of the shield machine 1. It includes two driving mechanisms-5, a plurality of steel cables-4 and longitudinal grooves 3. A plurality of longitudinal grooves 3 are equidistantly arranged on the casing of the shield machine 1 . The two driving mechanisms one 5 are both arranged in the shield machine 1 . The steel cable-4 is slidably fitted in the longitudinal groove 3, and the two ends of the steel cable-4 are linked with the two driving mechanisms-5 respectively. The driving mechanism one 5 includes a base plate 11 , a bracket 12 , a plurality of take-up wheels 1 8 , a plurality of linkage gears 7 , a driving gear 6 and a motor 1 9 . The bottom plate 11 is arranged on the inner wall of the shield machine 1 . The bracket 12 is arranged on the bottom plate 11 . The take-up wheel one 8 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com