Movable joint assembly

A technology of assembly and joint, applied in the directions of shafts and bearings, mechanical equipment, pivots, etc., can solve the problems of complex device structure and unstable angle locking, and achieve the effect of simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

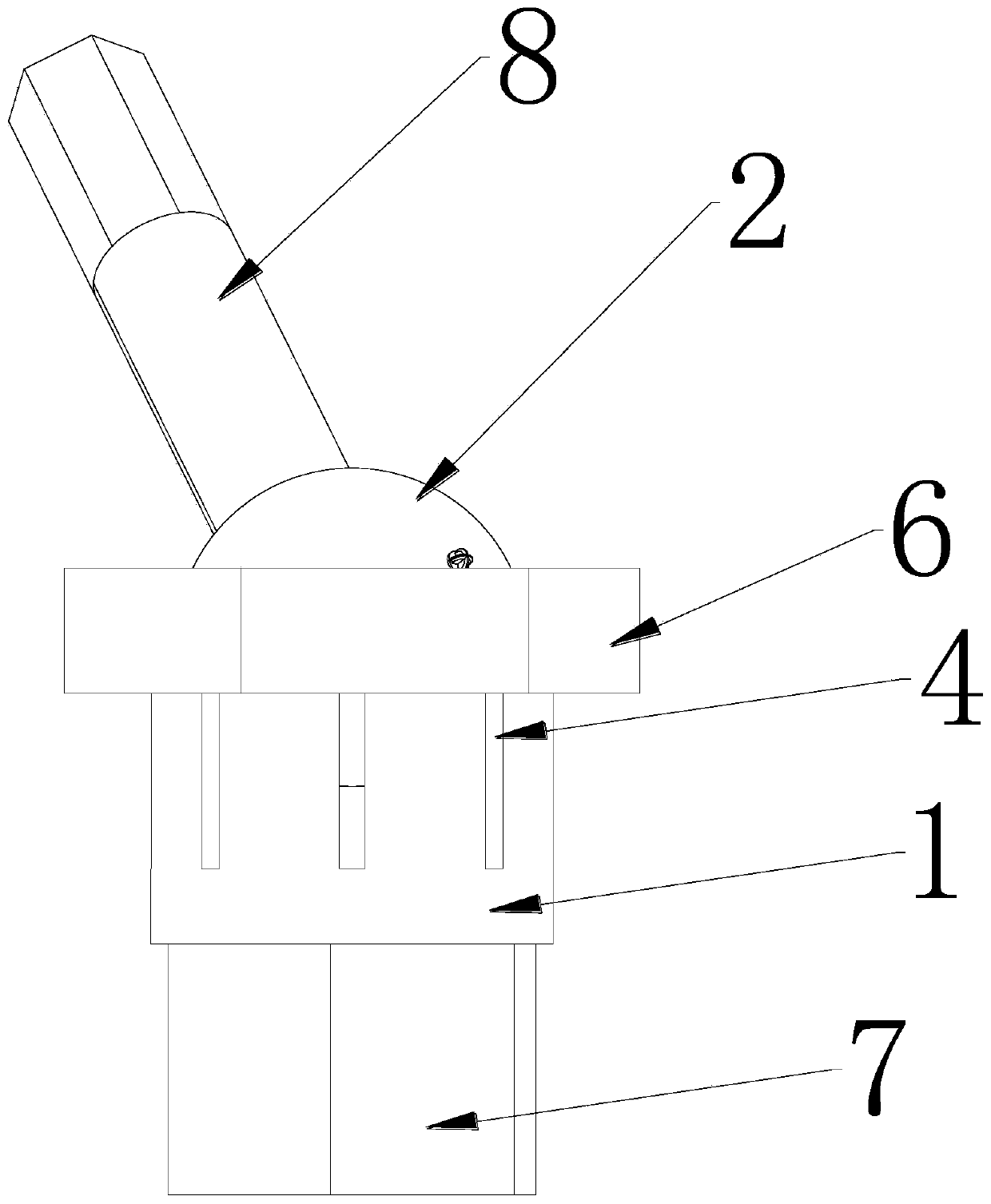

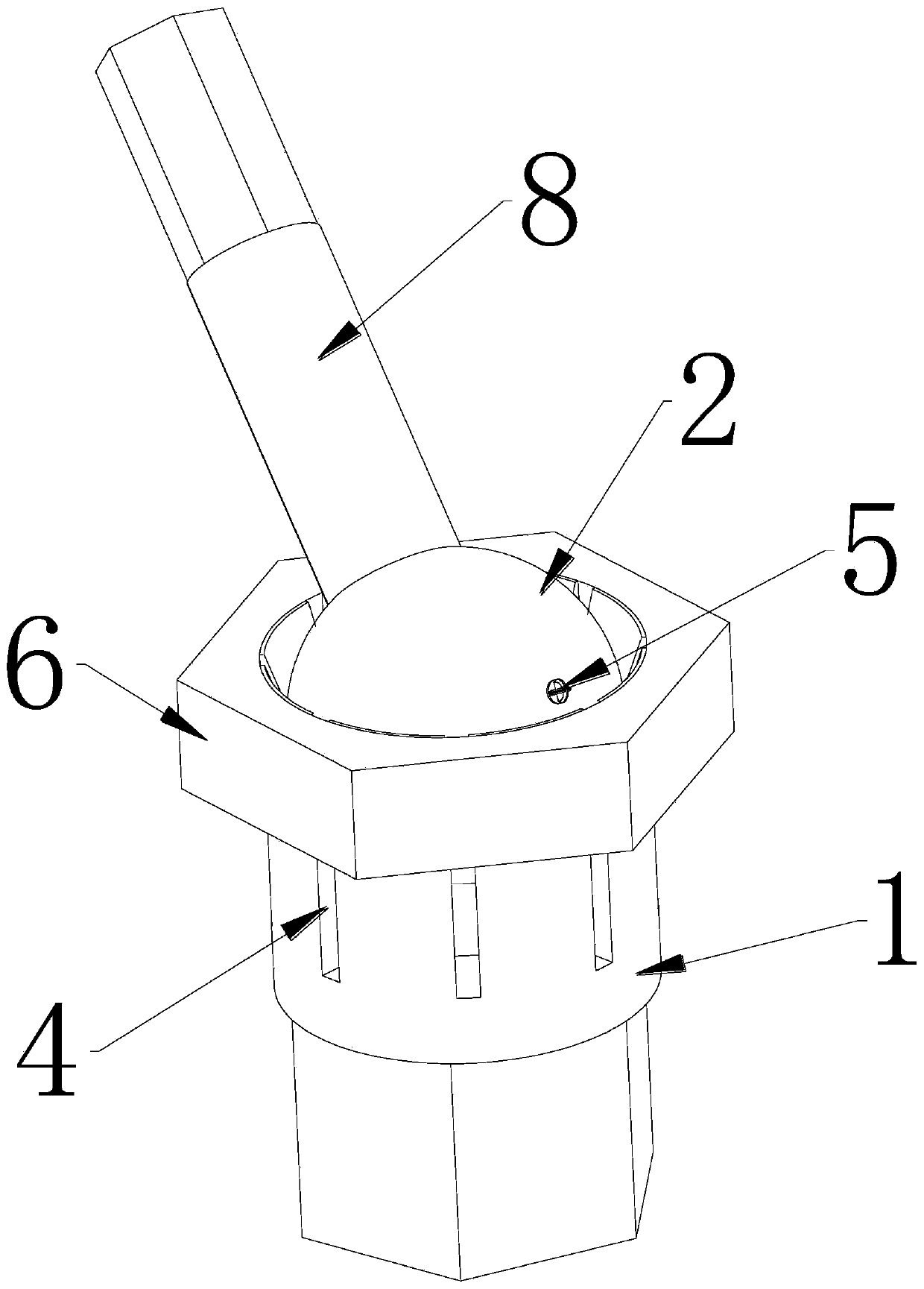

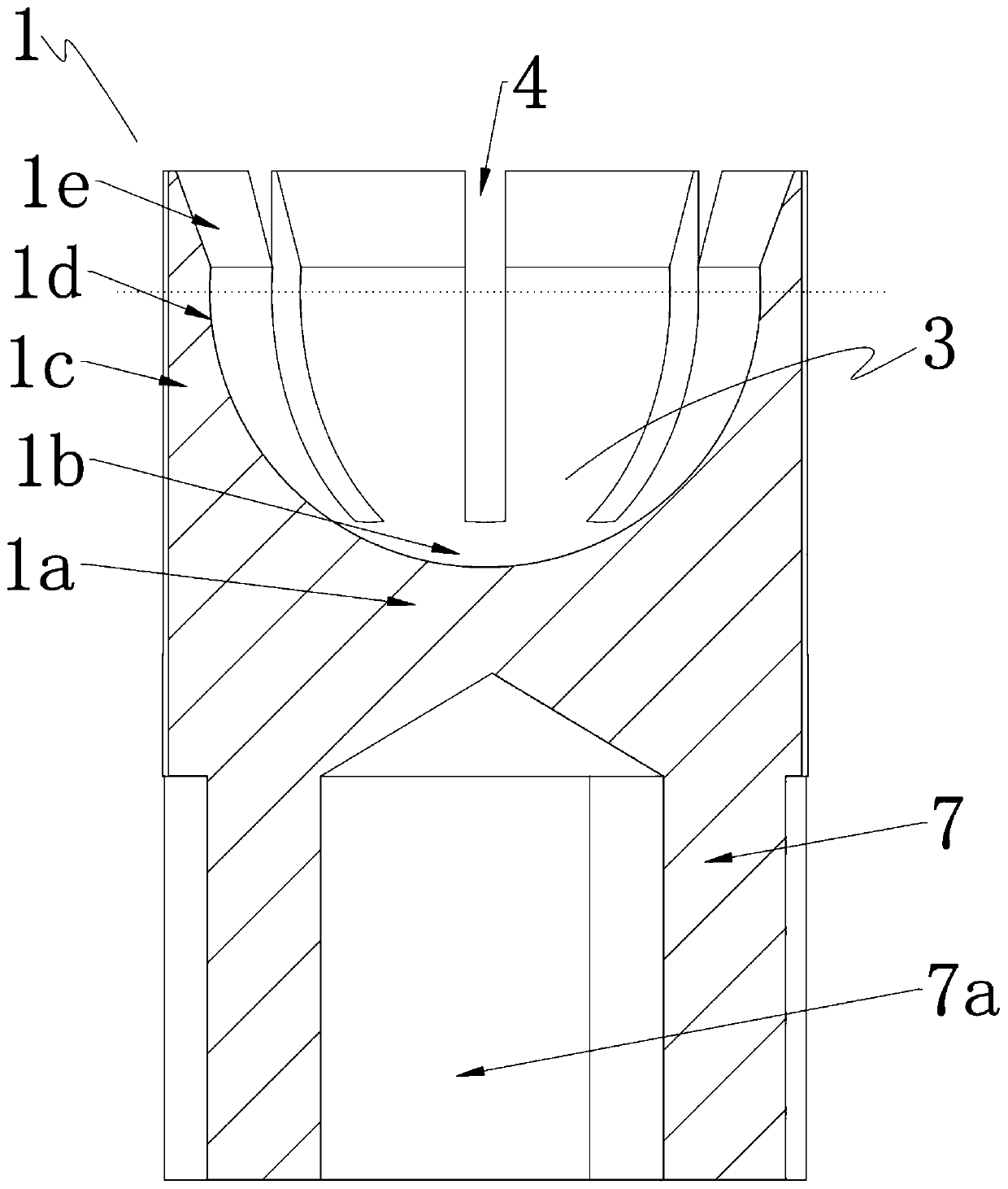

[0048] Such as Figure 1~4 As shown, a joint assembly includes a ball seat 1 and a ball head 2, the ball seat 1 includes a ball seat body, the ball seat body is provided with a ball head chamber 3, and the ball head chamber 3 is provided with a The adapted ball head 2. The ball seat body is provided with a bar-shaped notch 4, and the bar-shaped notch 4 extends out of the opening of the ball head chamber 3, and the ball seat body corresponding to the ball head chamber 3 is provided with an encircling locking mechanism 6 When the embracing locking mechanism 6 hugs the ball seat body corresponding to the ball head cavity 3 from the outside, the strip-shaped notch 4 allows the ball seat body parts on both sides to deform inward to press and lock the ball seat body. Describe the ball head 2.

[0049] The purpose of setting the bar-shaped notch 4 is: the existence of the bar-shaped notch 4 reduces the strength of the ball seat body at its location, and forms a space for making roo...

Embodiment 2

[0065] The difference from Embodiment 1 is that, as Figure 8 and 9 , the pressing protrusion 5 is fixedly arranged on the inner surface of the toothed portion 1c, and the outer surface of the ball head 2 is deformed when pressed by the pressing protrusion 5 . In this embodiment, the pressing protrusion 5 is provided on the inner surface of the tooth-shaped portion 1c, and the pressing protrusion 5 is conical. The hardness of at least the part near the outer surface of the ball head 2 is less than that of the pressing protrusion 5, and when the tooth-shaped portion 1c is pressed against the ball head 2, the pressing protrusion 5 is pressed into or pierces the outer surface of the ball head 2, such as Figure 10 and 11 shown.

[0066] This design makes the holding effect of the ball seat 1 to the ball head 2 better and more stable in the locked state. Further, pressure-sensitive adhesive may also be filled between the inner surface of the ball head cavity 3 and the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com