Liquid bismuth alloy quenching device and technology

A technology of quenching device and bismuth alloy, which is applied in the direction of quenching device, quenching agent, manufacturing tools, etc., can solve the problems of lead and Pb environmental pollution, and achieve the effect of no environmental pollution, excellent thermal conductivity, and good heat dissipation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

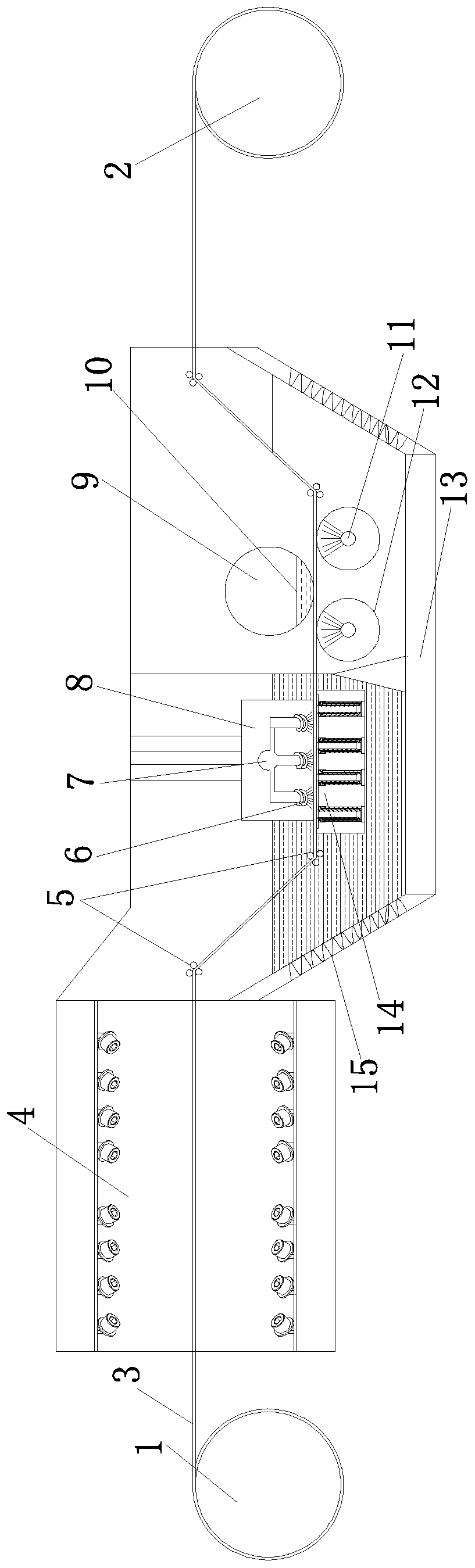

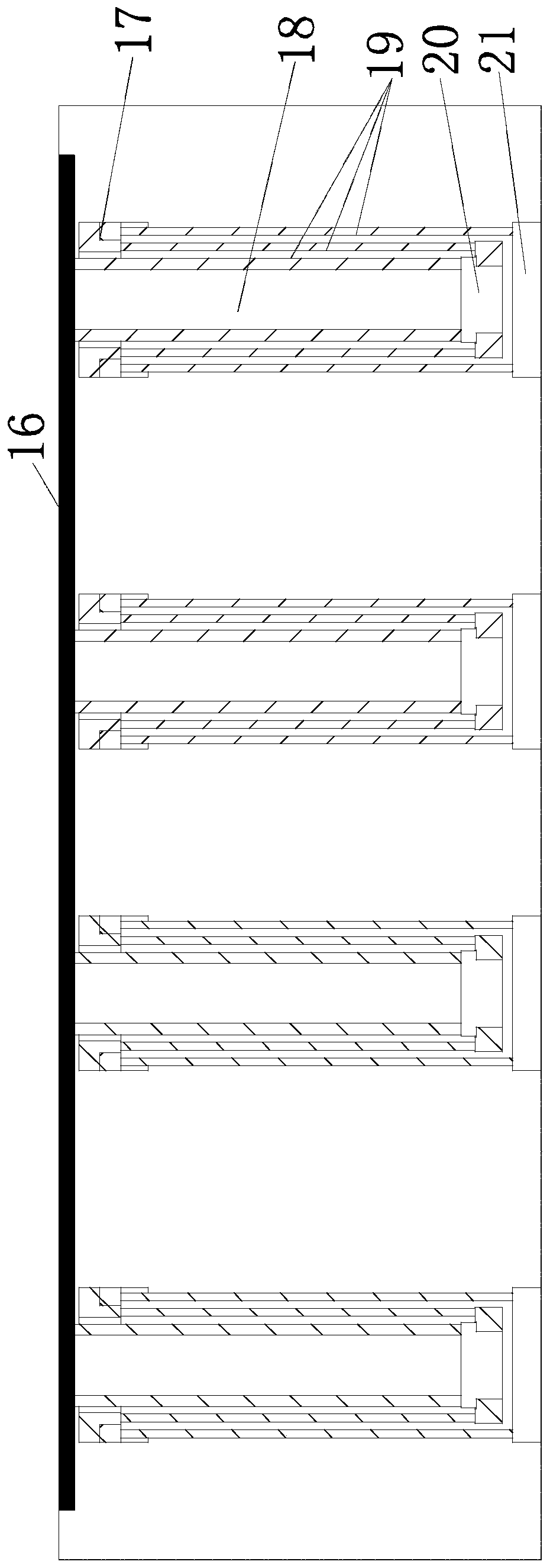

[0035] refer to figure 1 and figure 2 A structural schematic diagram of a liquid bismuth alloy quenching device and a structural schematic diagram of the lower platen are shown. A liquid bismuth alloy quenching device, comprising a curling wheel 1, a winding wheel 2, a steel belt connecting the curling wheel and the winding wheel 2, and a pair of steel strips are sequentially arranged between the curling wheel 1 and the winding wheel 2 There is a heating furnace 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com