G + G structure four-wire resistive touch screen

A four-wire resistive, touch screen technology, applied in electrical digital data processing, instruments, data processing input/output process, etc., can solve the limitation of the promotion and application of four-wire resistive touch screen, reduce the G+G structure touch screen operation force, etc. problems, to achieve the effect of improving the sense of touch experience, meeting market demands, and expanding the scope of the market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

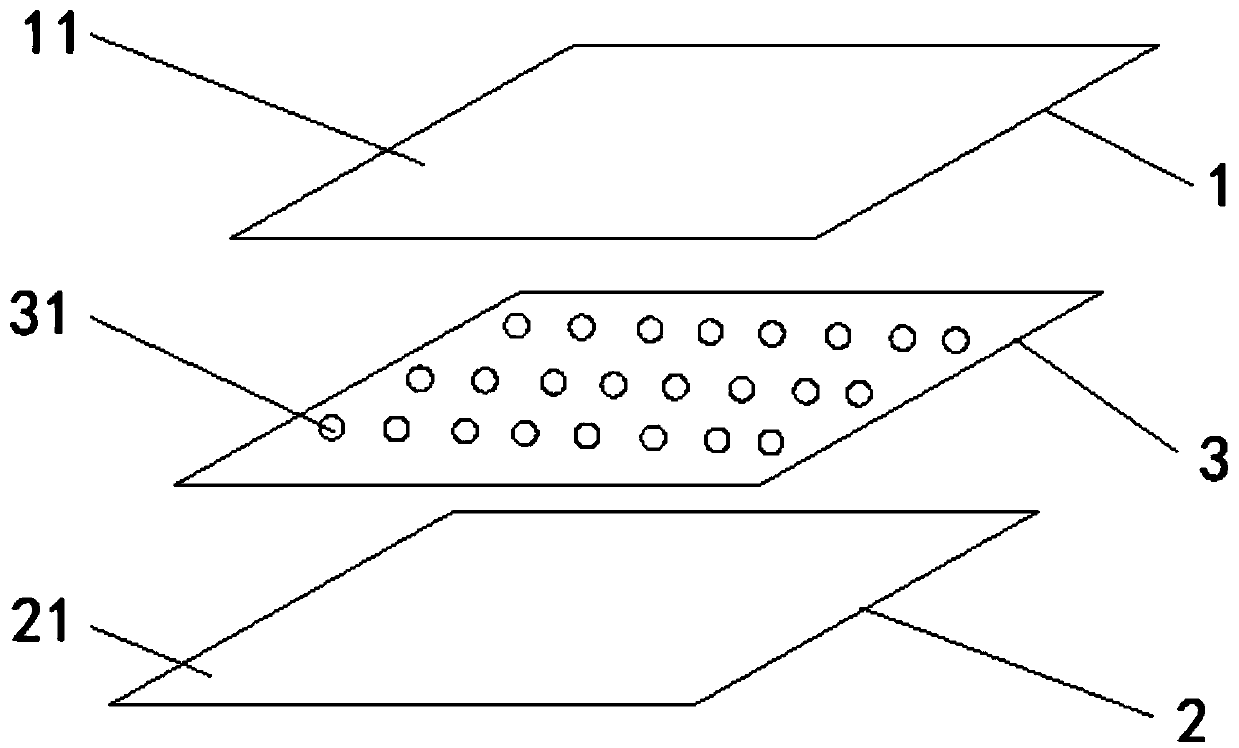

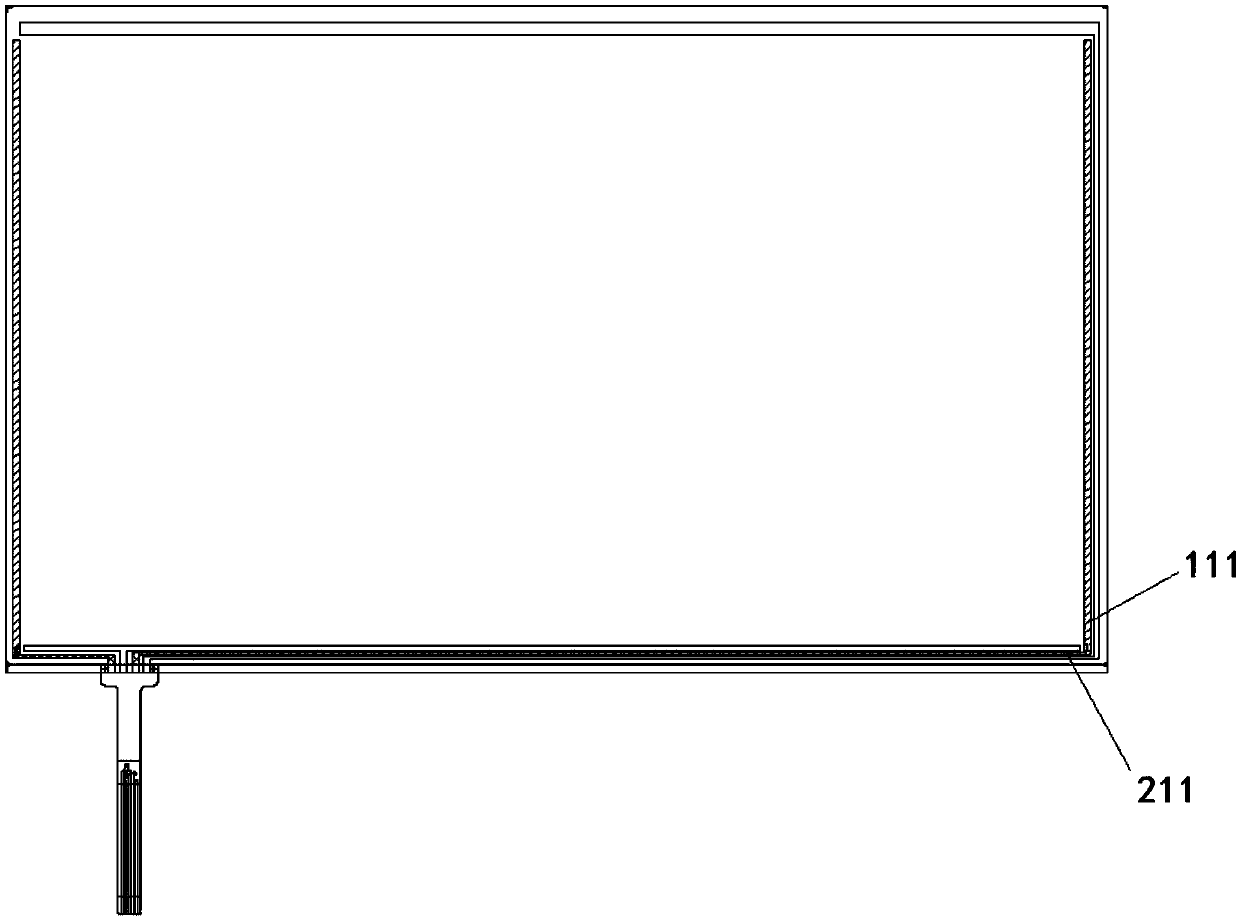

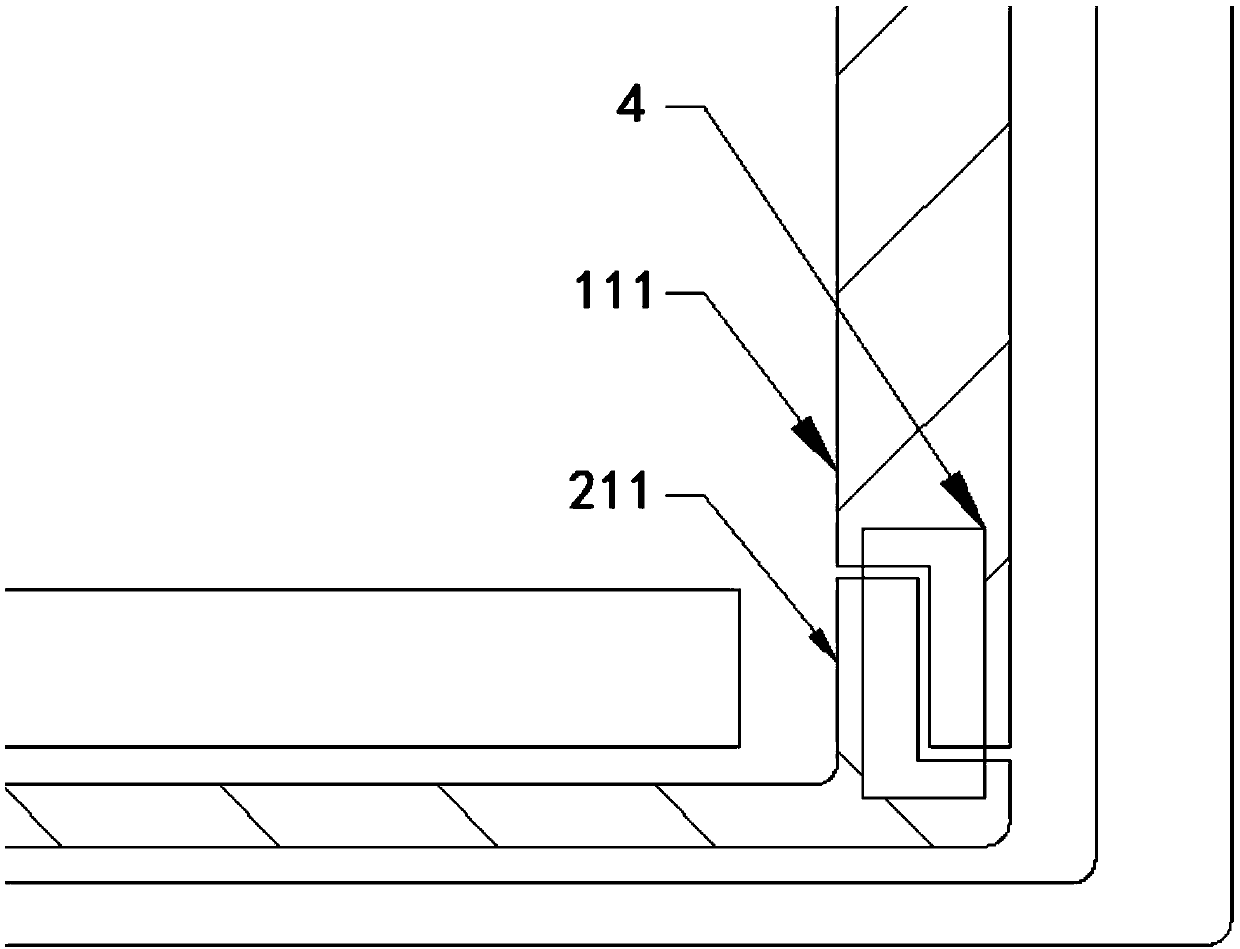

[0012] like Figure 1-Figure 3 As shown, a G+G structure four-wire resistive touch screen provided by the embodiment of the present invention includes an ITO conductive glass 1 and a base layer 2 sequentially arranged from top to bottom, and the surfaces of the ITO conductive glass and the base layer opposite to each other are respectively An upper circuit layer 11 and a lower circuit layer 21 are provided, the upper circuit layer 11 and the lower circuit layer 21 are respectively connected with at least two lead wires, the upper circuit layer 11 is provided with an upper silver wire 111, and the lower circuit layer 21 A lower silver wire 211 is provided; the upper silver wire 111 is connected with the lower silver wire 211 by silver dot glue 4, and the upper silver wire 111 at the connection (in order to distinguish, image 3 The area filled with the middle left slash is the upper silver line 111) and the lower silver line 211 (in order to distinguish, image 3 The area fill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap