Tray positioning detection method and device and intelligent forklift

A technology of pallet positioning and detection method, applied in image data processing, instrument, calculation and other directions, can solve problems such as poor efficiency, high failure rate, long recognition time, etc., to improve work efficiency and intelligence, improve recognition efficiency and Identify the success rate and enhance the effect of environmental anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

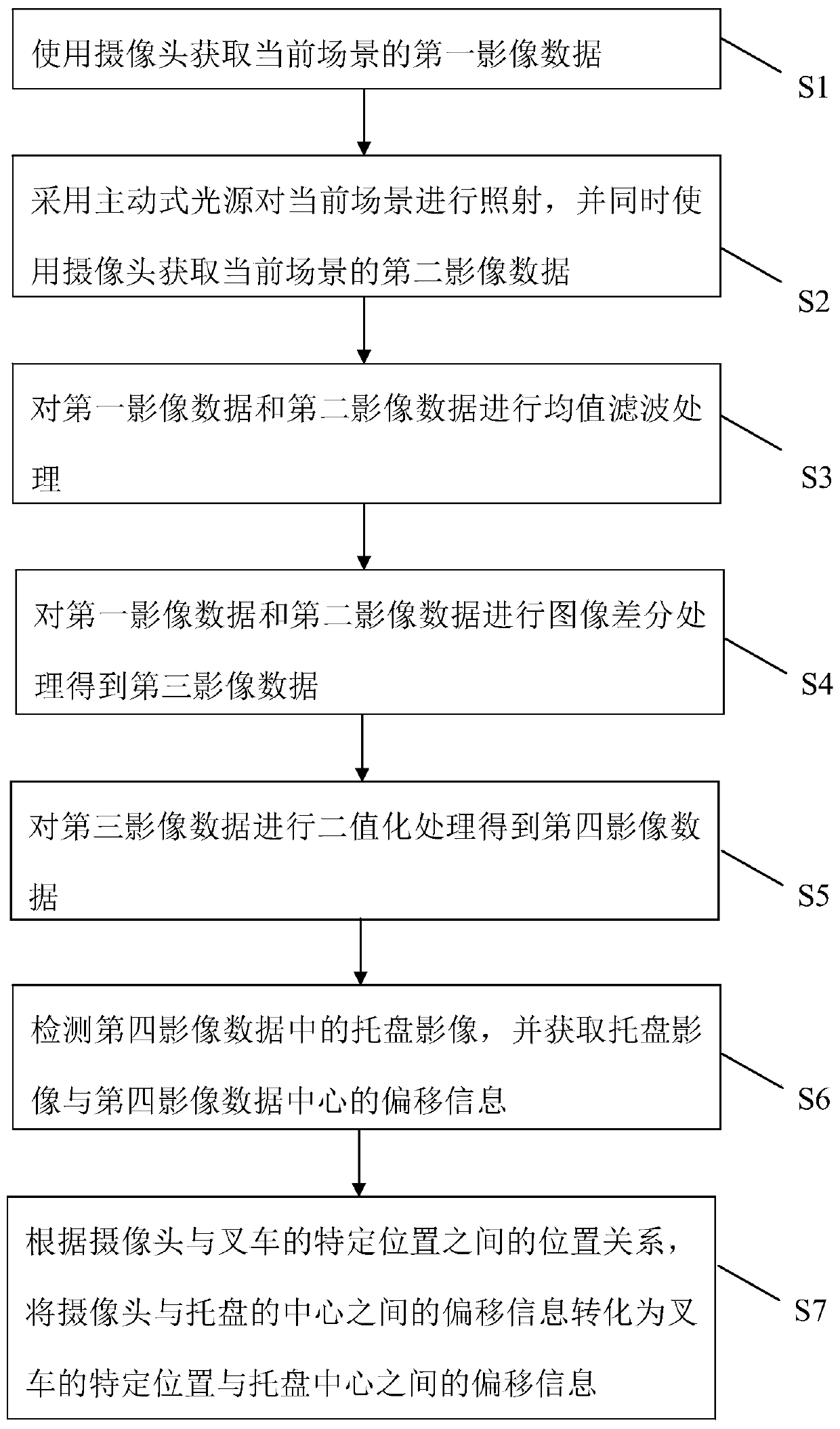

[0041] Such as figure 1 As shown, this embodiment discloses a pallet positioning detection method, the steps of which include:

[0042] S1. Use a camera to acquire first image data of a current scene.

[0043] Specifically, the current scene includes an image of the pallet, and specifically, in the image of the pallet, the side where the fork opening of the pallet is located is a rectangle with a known height.

[0044] S2. Use an active light source to irradiate the current scene, and simultaneously use a camera to acquire second image data of the current scene.

[0045] Specifically, in this embodiment, the active light source emits a laser beam with a fixed pattern to irradiate the current scene. Preferably, the active light source can simultaneously emit two parallel laser beams to irradiate the current scene, so as to enhance the anti-interference ability of the environment.

[0046] S3. Perform mean filtering processing on the first image data and the second image data...

Embodiment 2

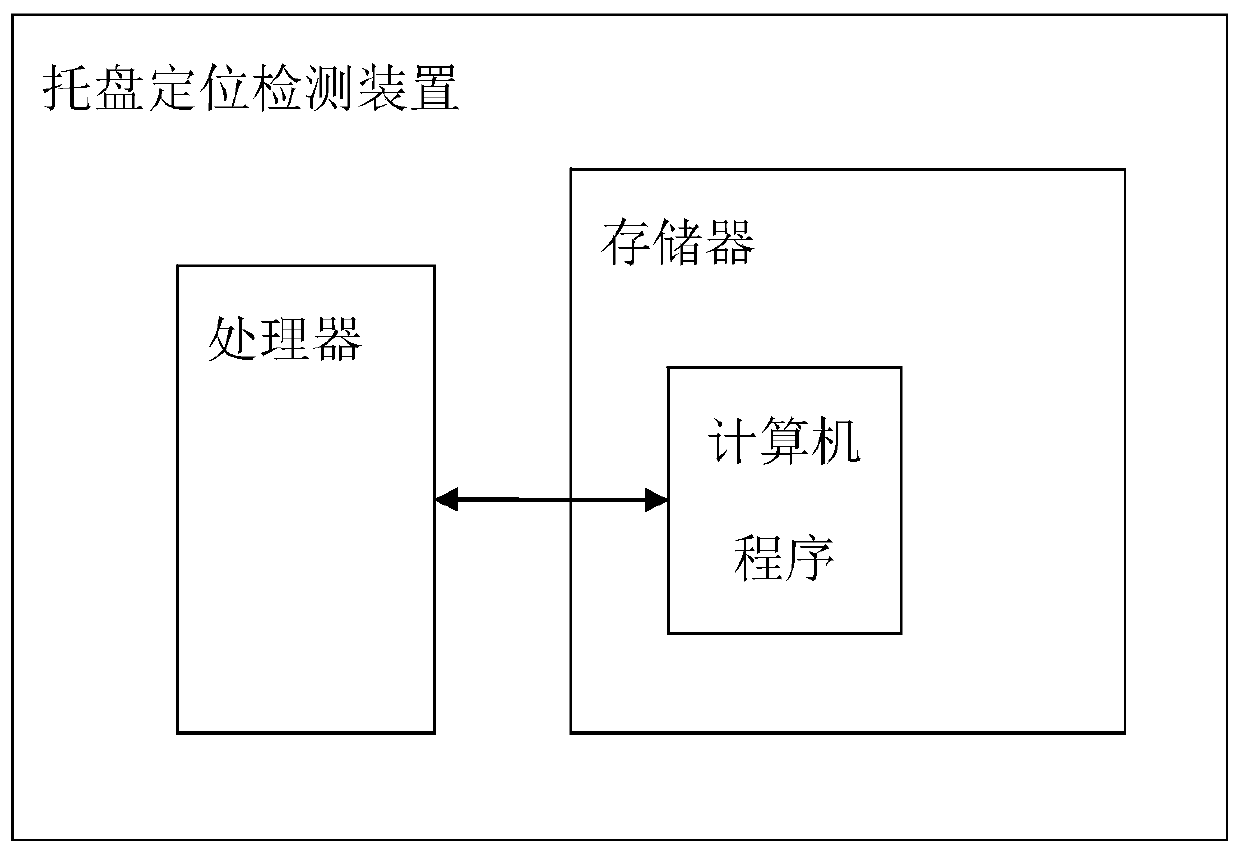

[0071] Such as figure 2 As shown, this embodiment discloses a pallet positioning detection device, including a processor; a memory; and a computer program, wherein the computer program is stored in the memory and is configured to be executed by the processor, and the processor executes the computer program to perform The steps in the pallet positioning detection method as described in Example 1.

Embodiment 3

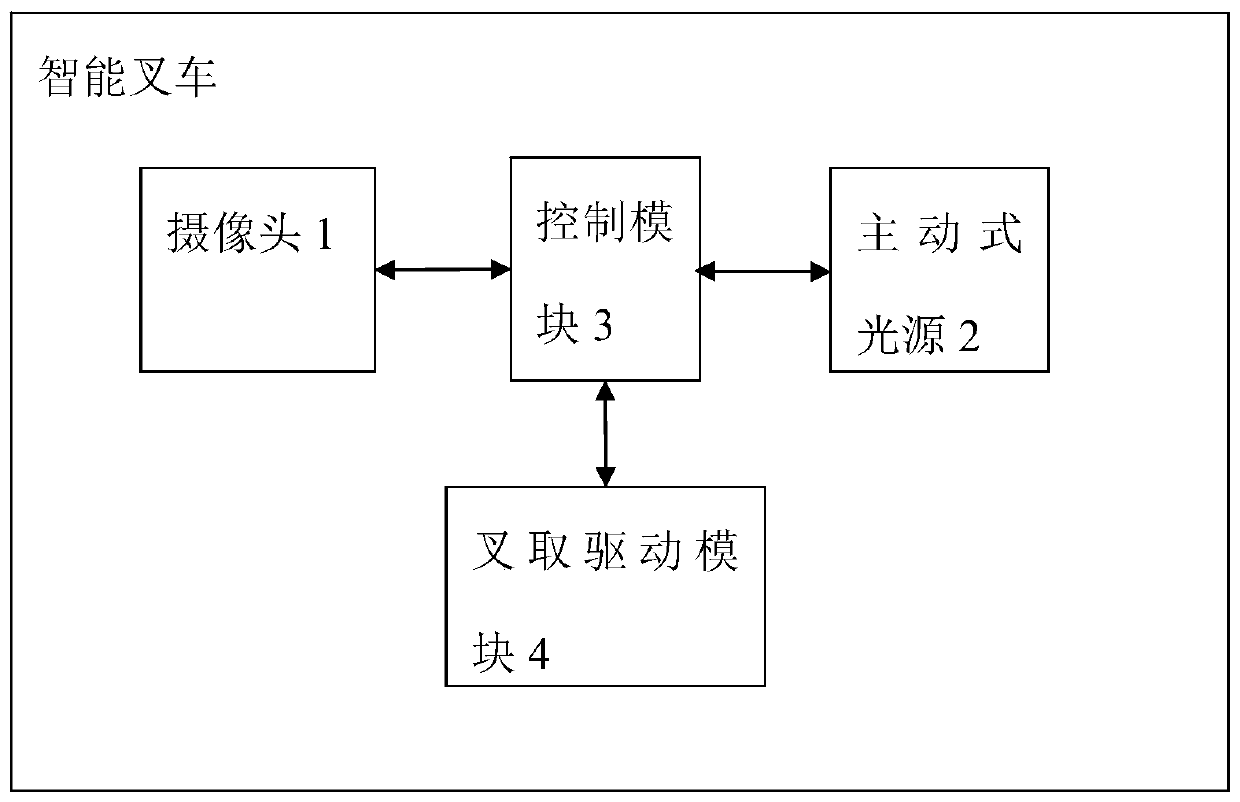

[0073] Such as image 3 As shown, this embodiment discloses an intelligent forklift, which includes a camera 1 , an active light source 2 , a control module 3 and a forklift driving module 4 . Specifically, the camera 1 is used to obtain the image data of the current scene; the active light source 2 is used to illuminate the current scene; the control module 3 is electrically connected to the camera 1, the active light source 2 and the fork drive module 4, and is used to execute such as The steps in the pallet positioning detection method described in Embodiment 1 are to obtain offset information, and generate a control command according to the offset information and transmit it to the fork-taking drive module 4; the fork-take drive module 4 is used to fork the pallet according to the control command Pick.

[0074] Specifically, the forklift driving module 4 may include a driving part of the forklift and an up and down driving part of the fork rod. Specifically, the control m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com