Flowmeter support welding fixture

A technology for welding tooling and flowmeters, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low production efficiency, inability to solve mass production of flowmeter brackets, and reduced product productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

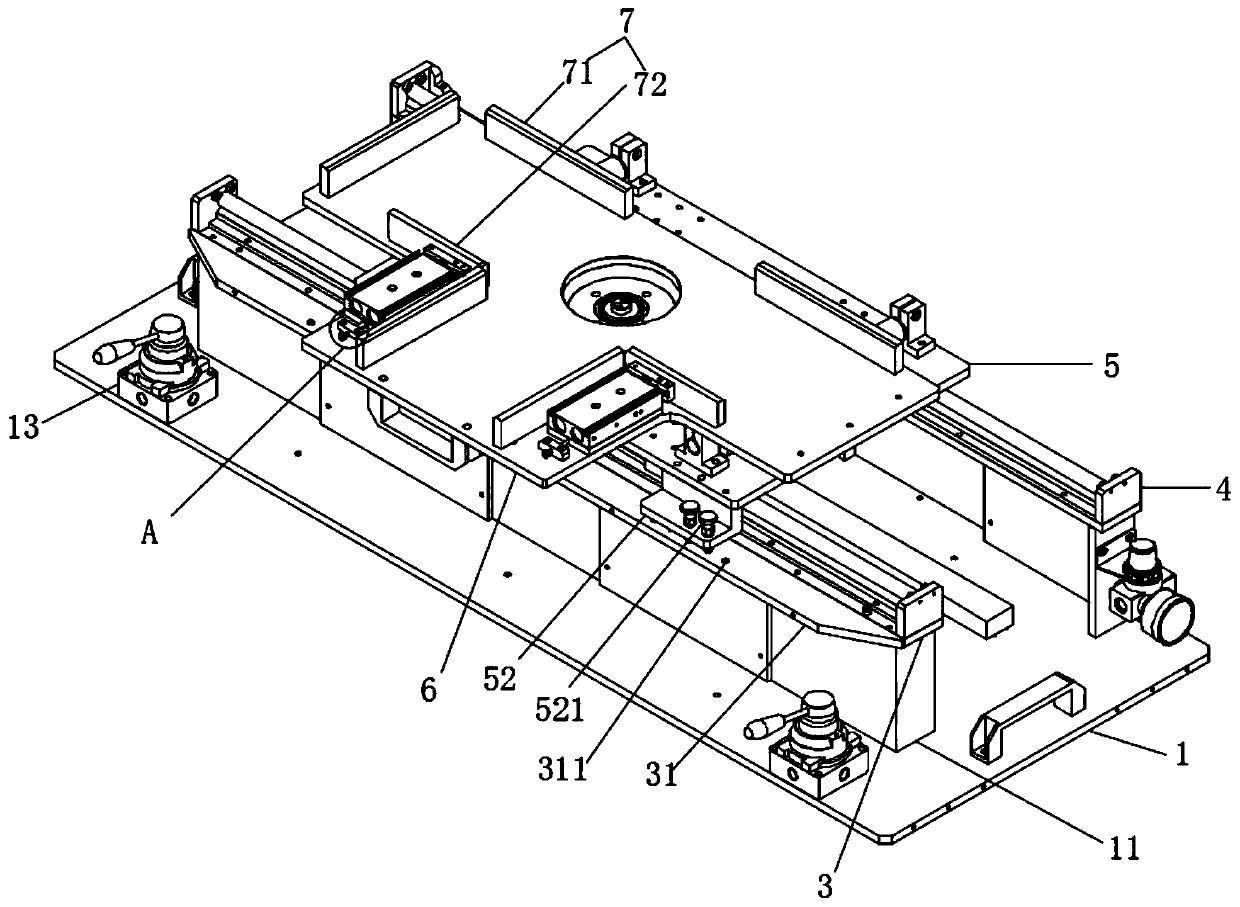

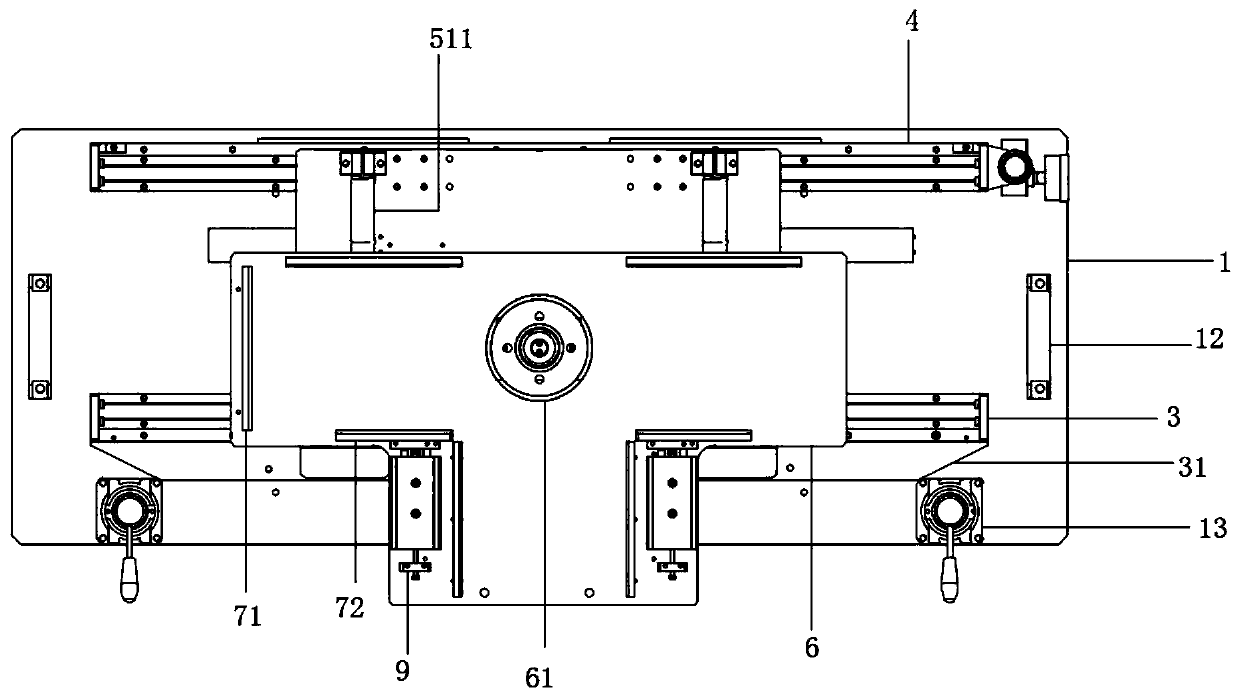

[0025] see Figure 1 to Figure 5 , the figure shows a flowmeter bracket welding tool provided by Embodiment 1 of the present invention, mainly provided with a bottom plate 1, and supporting plates 11 are respectively arranged on both sides of the bottom plate 1, and the two supporting plates 11 are arranged in parallel along the length direction of the bottom plate 1 , the first slide rail 3 and the second slide rail 4 are respectively arranged on the two supporting plates 11, the first slide rail 3 and the second slide rail 4 are slidably connected with the slide seat 5, and the slide seat 5 is provided with two parallel first slide rails. Three slide rails 51, two third slide rails 51 are slidably connected with a positioning plate 6, the positioning plate 6 is T-shaped at a top view angle, and the positioning plate 6 is provided with several limiting plates 7, and several limiting plates 7 are arranged along the The circumferential direction of the positioning plate 6 is ar...

Embodiment 2

[0033] see Figure 1 to Figure 5 , the figure shows a flowmeter bracket welding tool provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first slide rail 3 A fixed plate 31 extends outward from one side of the fixed plate 31 , and a plurality of positioning holes 311 are opened on the fixed plate 31 , and the plurality of positioning holes 311 are arranged along the length direction of the fixed plate 31 . The fixing plate is integrated with the base of the first slide rail, which is convenient for installation, and the positioning hole is a screw hole, which can fix the slide seat after the slide seat is adjusted, thereby improving the welding quality. The two ends of the fixed plate have bevels, which can provide the operation space of the pneumatic clamp.

Embodiment 3

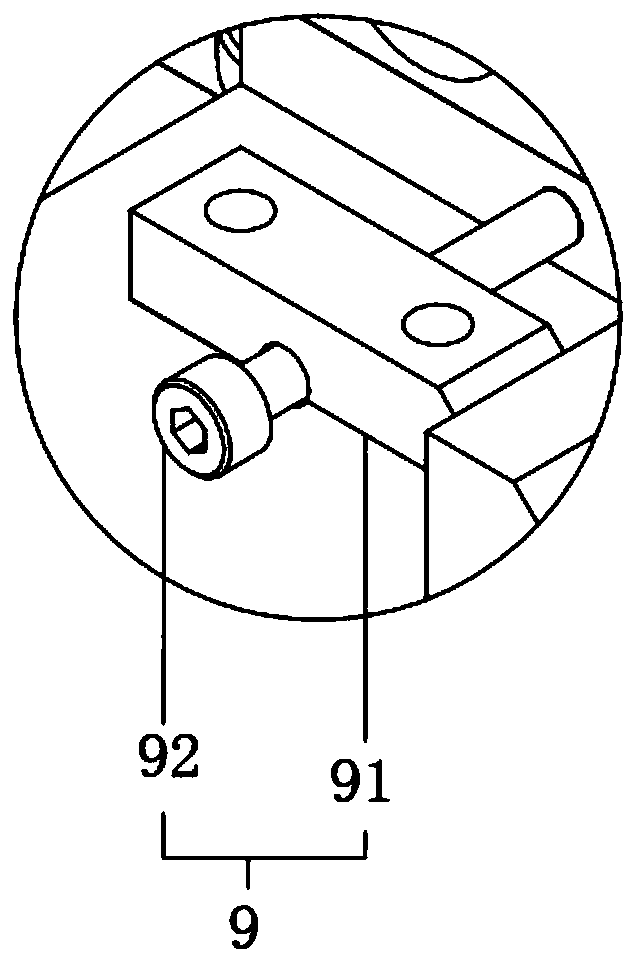

[0035] see Figure 1 to Figure 5 , the figure shows a flowmeter bracket welding tool provided by the third embodiment of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: the sliding seat 5 is close to the first One side of a slide rail 3 is provided with at least one fixing block 52 , and a fixing rod 521 matching the positioning hole 311 is detachably connected to the fixing block 52 . The cross section of the fixing block 51 is L-shaped. The fixed rod is a screw rod, so that the fixed rod matches the positioning hole, so that the fixed rod can be easily disassembled, so that the position of the positioning plate can be adjusted conveniently, and the work efficiency can be improved. Moreover, the bottom of the L-shaped fixing block can resist the slide rail, and can also play the role of supporting the slide seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com