Method and equipment for manufacturing thin-wall plough disc harrow blade

A disc harrow, thin-walled technology, applied in the field of farming plows, can solve the problems of not too large tool feed, workpiece vibration, low processing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

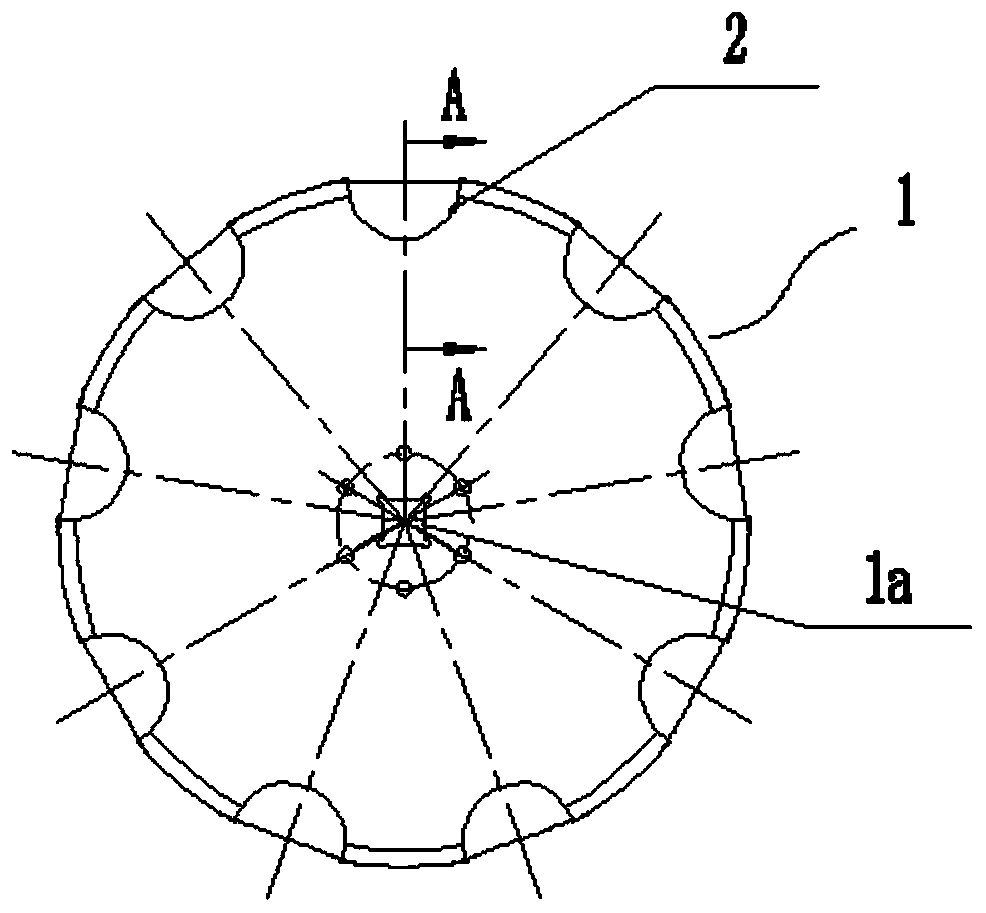

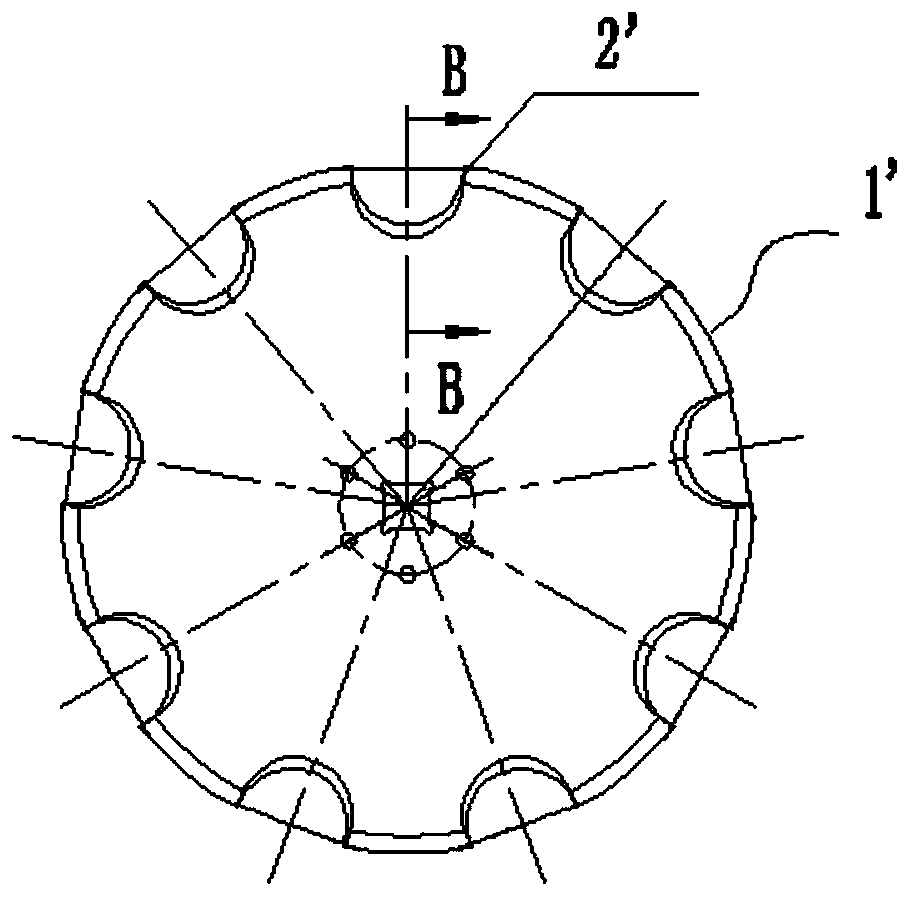

[0033] Such as Figure 5-Figure 7 Shown is a schematic diagram of the structure of the device for making thin-walled plough disc harrow blades provided by the present invention, in which, Figure 5 , Image 6 Shows the blank to be ground on the positioning disc, Figure 7 The blank to be ground is not shown.

[0034] by Figure 5-Figure 7 It can be seen that the equipment of the present invention includes: a grinding mechanism with a grinding wheel for grinding the to-be-ground arc gap of the thin-walled plough disc harrow blade blank to make it into a crescent-shaped cutting edge; and a positioning mechanism , With a positioning disc on one side of the grinding wheel for fixing the blank, with an arc hole used to coincide with the arc gap of the blank to be ground; wherein the blank is a thin-walled and stamped The blank disc harrow blade with the arc notch to be ground on the edge, preferably, the blank part is a thin-walled steel part formed by stamping; wherein, when the bla...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap