Car loader

A technology of loading machines and packaging devices, which is applied in the directions of conveyors, loading/unloading, transportation and packaging, etc., and can solve problems such as easy deviation of the dropping position and inability to stack neatly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

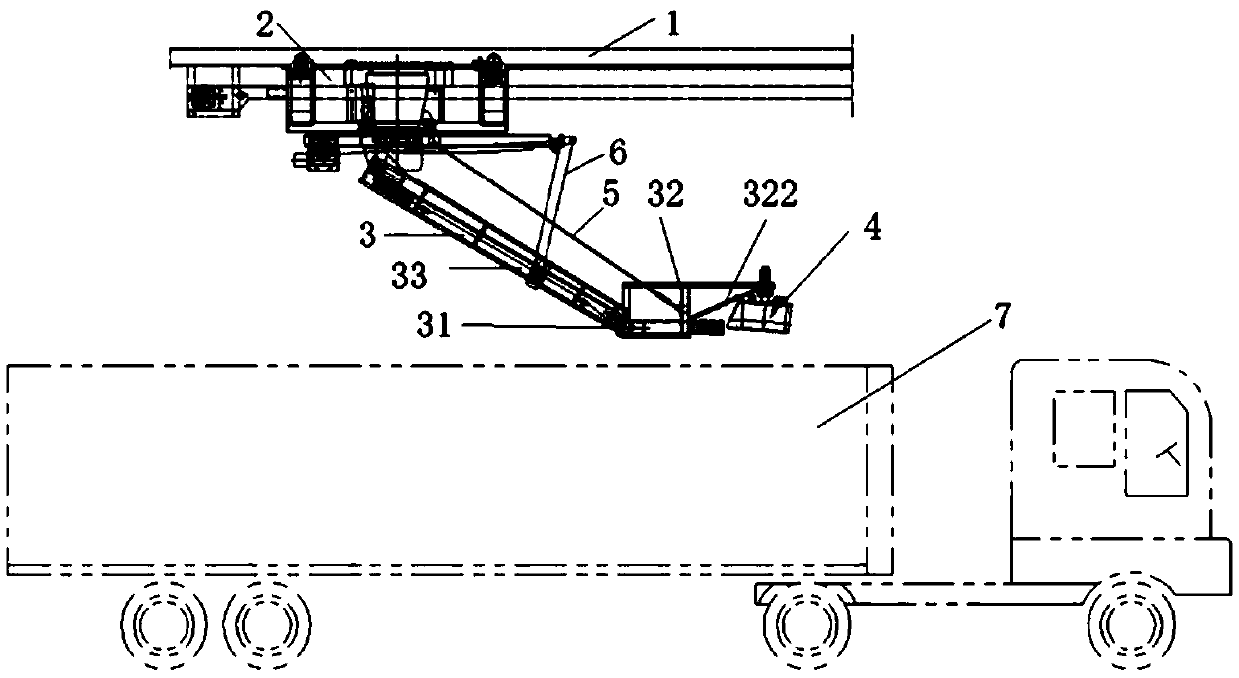

[0025] Such as figure 1 As shown, it includes a guide rail 1, an upper bag receiving device 2 guided and assembled on the guide rail 1, a lower belt conveying device 3 connected to the lower side of the upper receiving device 2, and a bag releasing device 4 connected to the lower side of the lower belt conveying device 3 . During use, the bag in the bag-connecting device 2 enters the bag-releasing device 4 through the sliding belt conveyor 3, and the bag-releasing device 4 packs the bag in the vehicle 7.

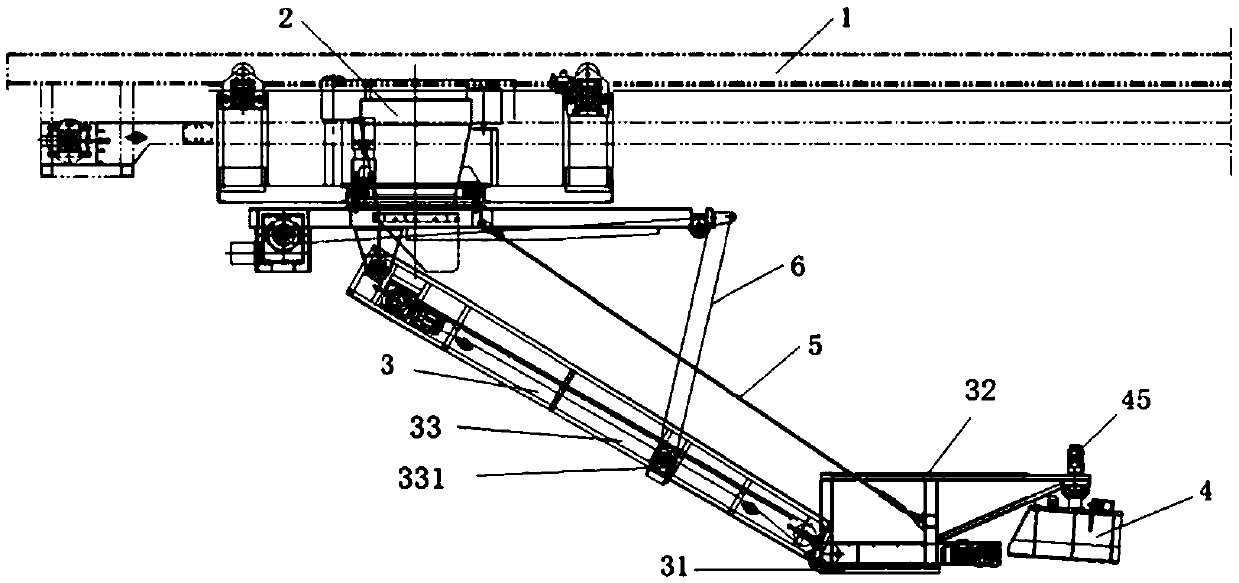

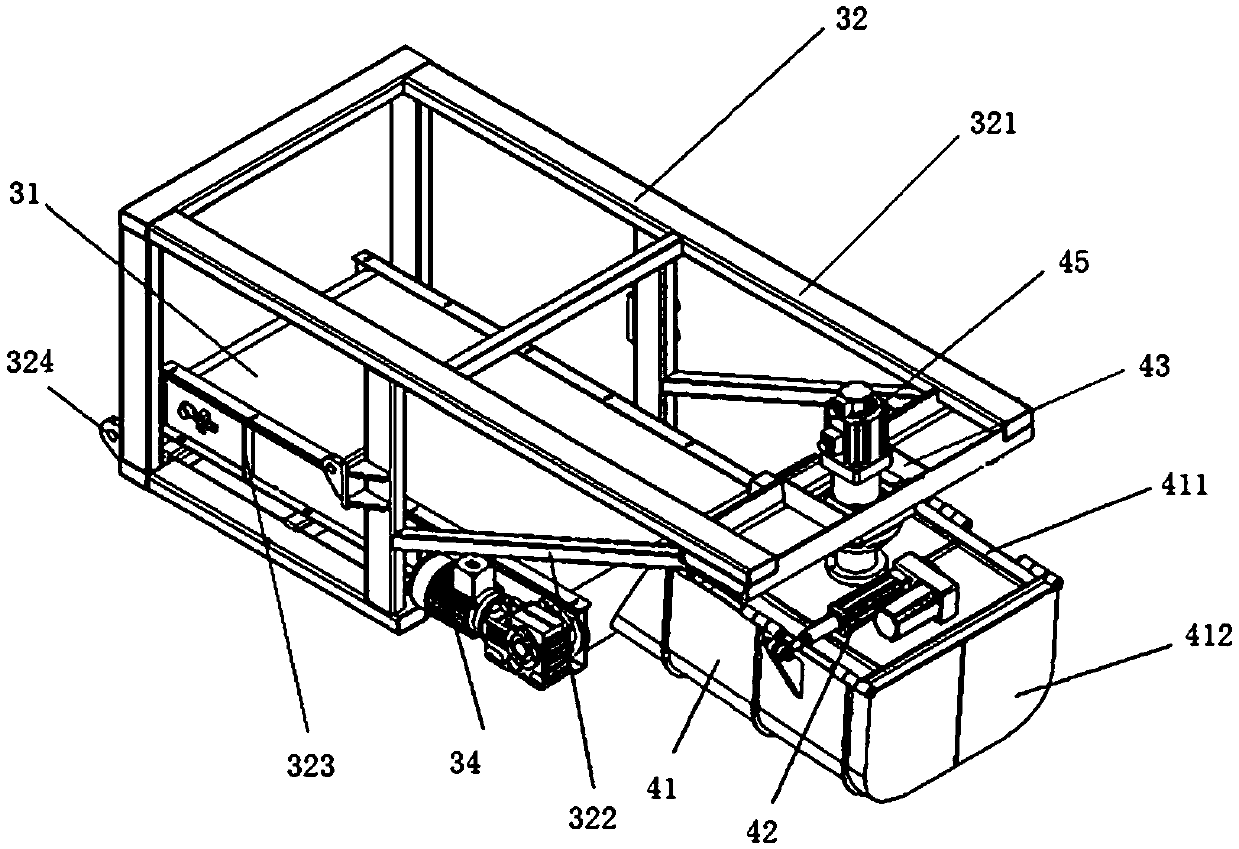

[0026] Such as figure 2 Shown, slide belt conveyer 3 comprises inclined belt conveyer 33 and horizontal belt conveyer 31, the left end of inclined belt conveyer 33 is hinged on the lower side of bag device 2, and the right end of inclined belt conveyer 33 is hinged on horizontal belt The left end of the conveyor 31, and the left end of the conveying part of the inclined belt conveyor 33 corresponds to the outlet of the upper connecting bag device 2 to form the entrance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com