Method and device for vibration reduction of arm support

A boom and luffing oil cylinder technology, applied in the field of fire safety, can solve the problems of real-time adjustment of the inoperable state of the slope setting, deviation from the working position, collision with external obstacles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

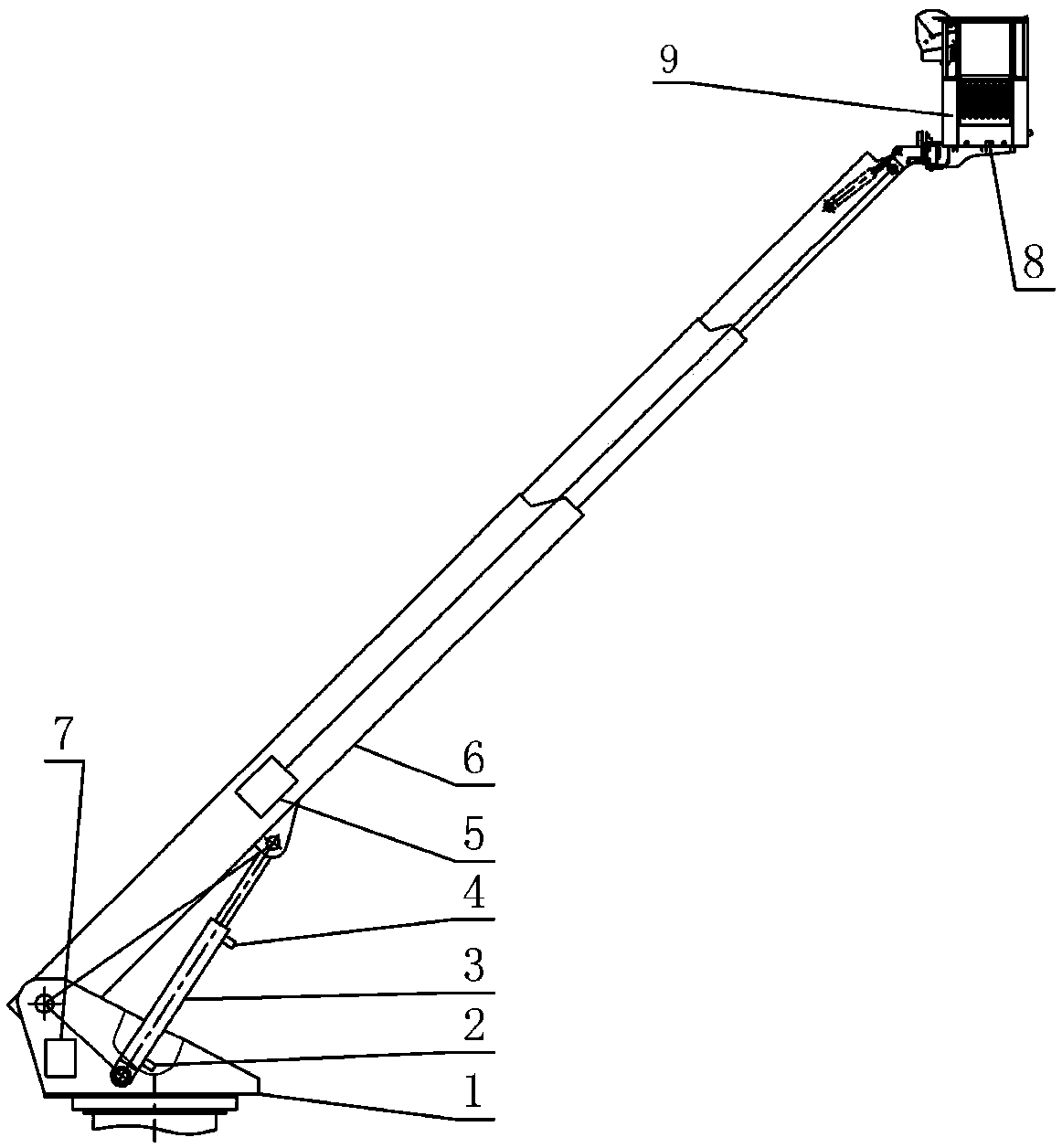

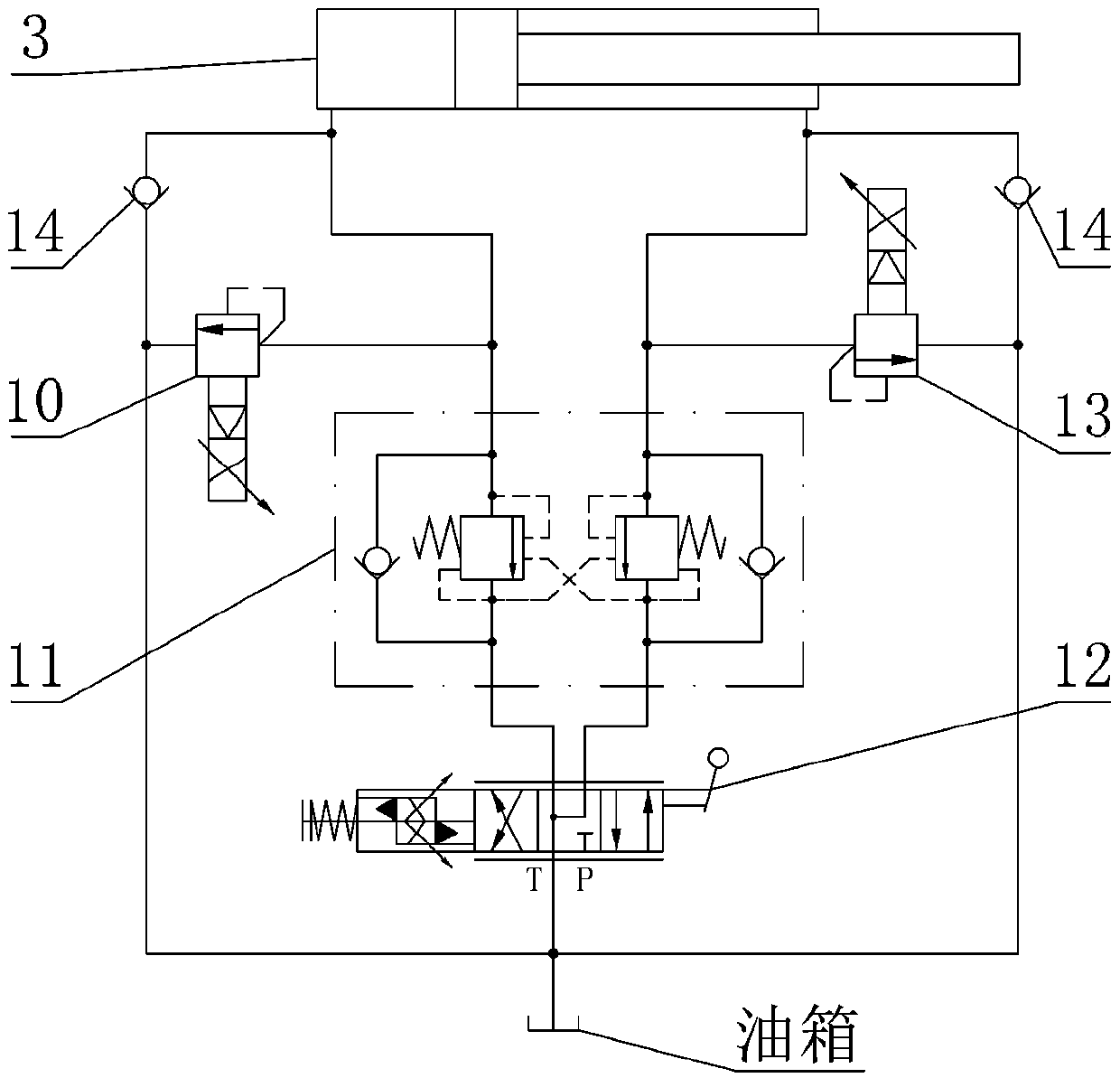

[0029] see figure 1 As shown: a device for boom vibration reduction provided in this embodiment, including a turntable 1, an oil pressure sensor 2, a luffing cylinder 3, an oil pressure sensor 4, a long angle sensor 5, a luffing jib 6, a control Device 7, weighing sensor 8, working platform 9, electro-hydraulic proportional overflow valve 10, two-phase balance valve 11, electro-hydraulic proportional reversing valve 12 and electro-hydraulic proportional overflow valve 13.

[0030] The turntable 1 described in this embodiment is a rotary platform, which is connected with the lower vehicle body through a slewing support. A controller 7 is installed on the turntable 1 to collect sensor signals (such as oil pressure sensor 2, oil pressure sensor 4, long angle sensor 5, weighing sensor 8) and perform analysis and calculation, and output control signals to execute according to the established program. mechanism, such as electro-hydraulic proportional relief valve 10, electro-hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com