Improved anti-breaking shock absorber

An anti-fracture, improved technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as short service life, low safety factor, and surface damage of piston rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

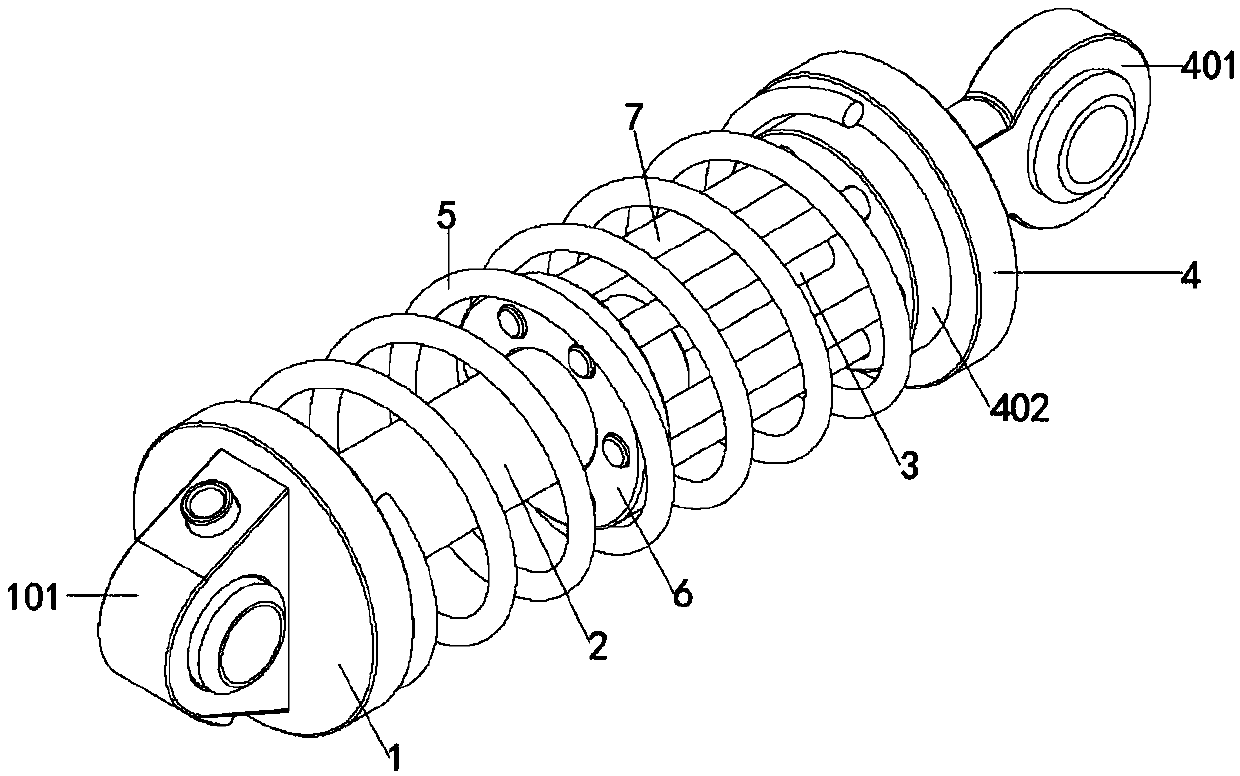

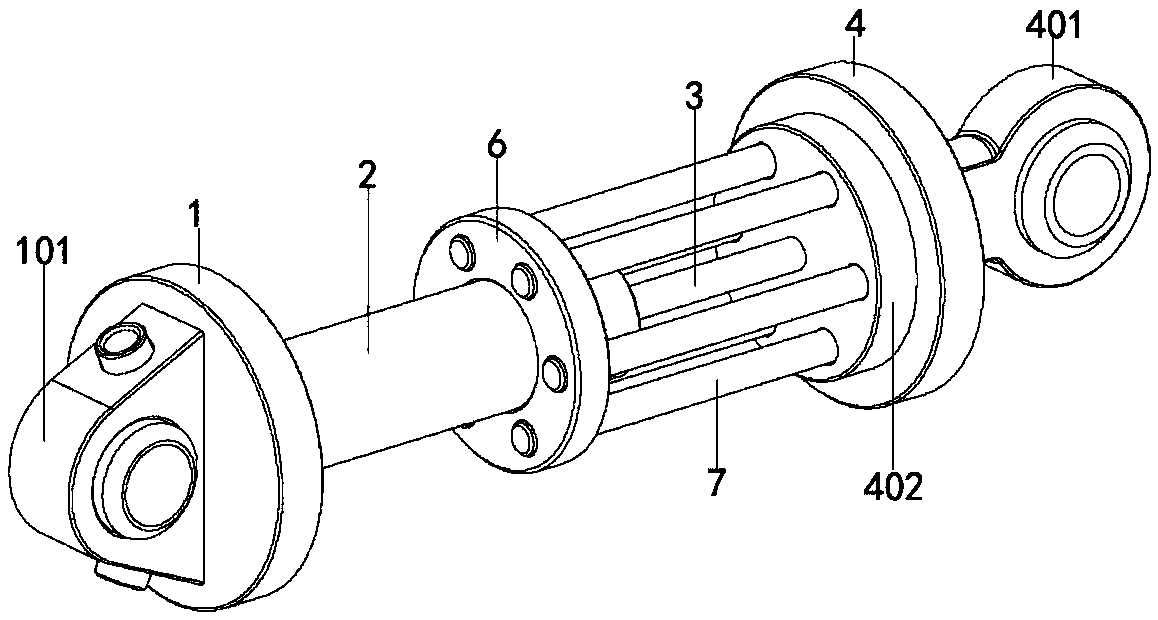

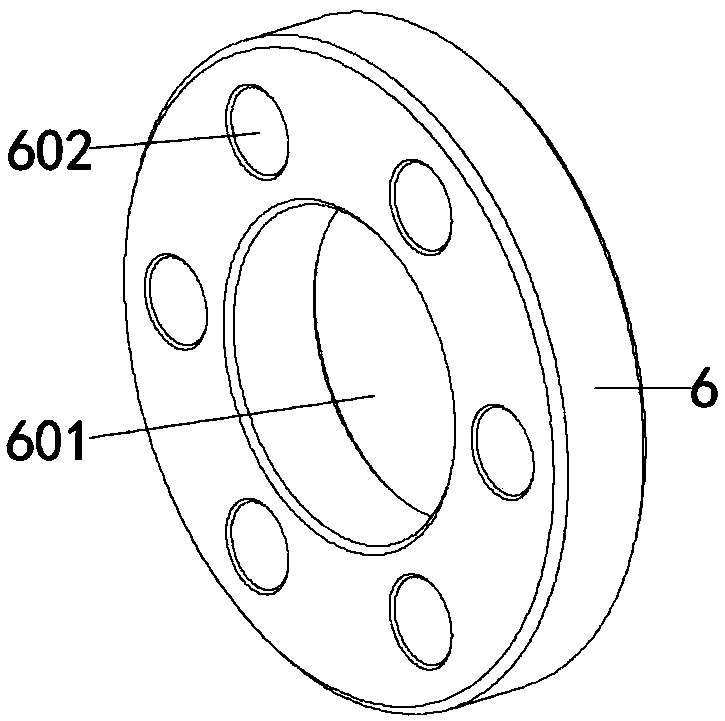

[0027] An improved anti-fracture shock absorber, including: a first fixed block 1, a damping cylinder 2, a piston rod 3, a second fixed block 4, a shock absorbing spring 5, a slip ring 6, a connecting rod 7, and a first installation earring 101 , the second installation earring 401, the inlay seat 402, the sliding matching hole 601, the inlay hole 602; the first fixed block 1 is cylindrical, and the front end of the first fixed block 1 is welded with the first installation earring 101; the first fixed block 1 The rear end of the damping cylinder 2 is welded, and the inside of the damping cylinder 2 is slidingly equipped with a piston rod 3; the rear end of the piston rod 3 is welded with a cylindrical mosaic seat 402, and the rear end of the mosaic seat 402 is welded with a cylindrical first Two fixed blocks 4, and the rear end of the second fixed block 4 is welded with a second installation earring 401; the front end of the mosaic seat 402 is inlaid with a cylindrical connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com