Silicon controlled rectifier light modulation Bleeder circuit

A dimming control circuit and silicon dimming technology, applied in the field of LED dimming, can solve the problems of poor compatibility, poor dimming performance of thyristor, insufficient dimming depth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

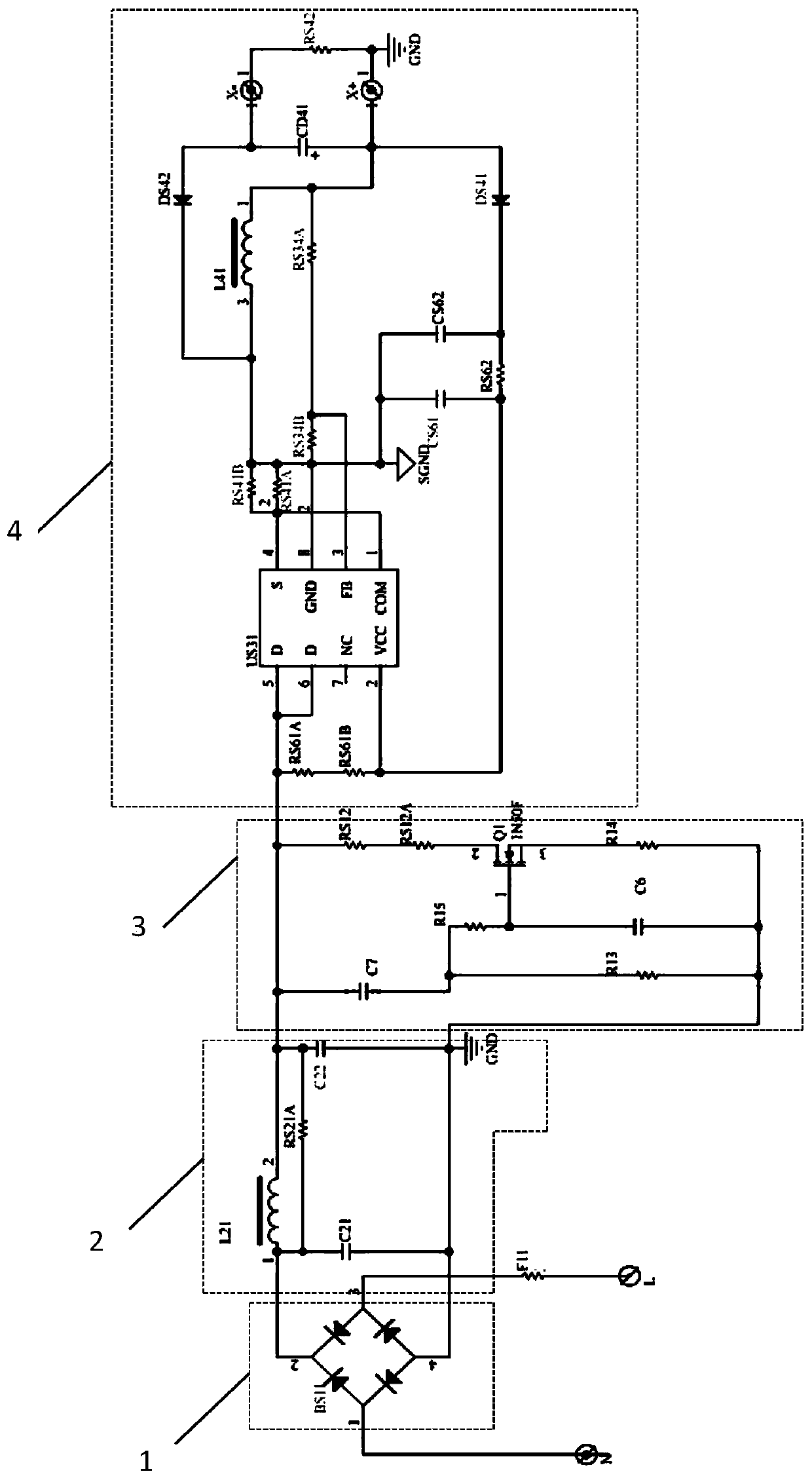

[0024] Example: such as figure 1 As shown, a schematic diagram of a thyristor dimming Bleeder circuit 3 is composed of a rectifier circuit 1, a filter circuit 2, a Bleeder circuit 3 and a dimming control circuit 4. The dimming control circuit 4 is composed of a driver U31 and a driver U31 respectively. The peripheral control circuit is composed of pins connected electrically. The driver U31 is MP4088LED driver. The MP4088LED driver has fast start-up speed, low delay, and the power derating at high temperature makes the system flicker-free when the ambient temperature is high. The input end of the rectification circuit 1 is electrically connected to the power supply, the output end of the rectification circuit 1 is electrically connected to the input end of the recording and broadcasting circuit, the output end of the filter circuit 2 is electrically connected to the input end of the Bleeder circuit 3, and the output end of the Bleeder circuit 3 is electrically connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com