PCB and preparation method thereof

A kind of PCB board, process edge technology, applied in the field of PCB board and its preparation, can solve the problem of spending a lot of time and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

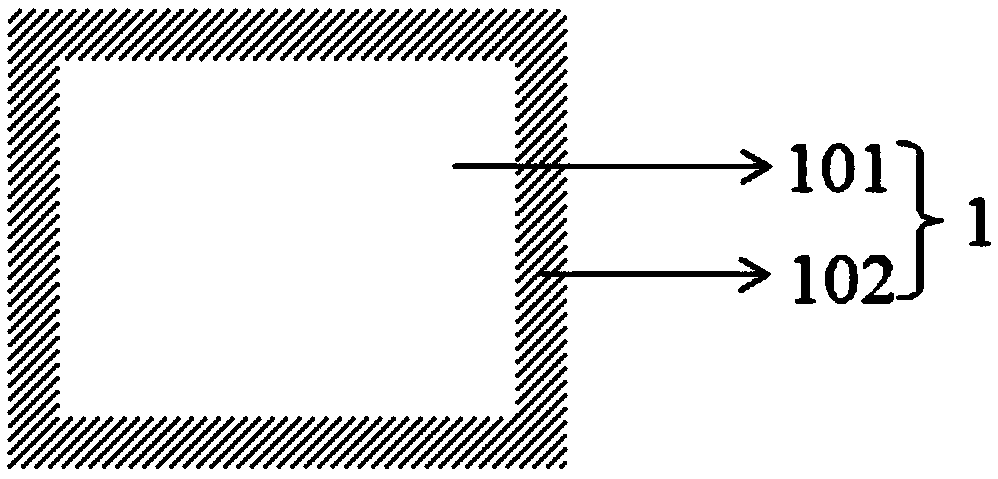

[0030] like figure 1 As shown, this embodiment provides a PCB board, which is composed of a PCB graphic area 101 and a process edge 102 .

[0031] Among them, the width of the process side is 10mm, and it is composed of four processing parts connected to each other from the end to the end. The processing part has a copper foil layer, and two air guide grooves with a width of 5cm are arranged on the copper foil layer.

[0032] The preparation method is as follows: the copper clad laminate is sequentially cut, drilled, copper plated, exposed and developed, etched and washed, browned, laminated, pressed, and the outer layer PCB pattern is made to obtain the PCB board.

[0033] Wherein, the film pattern used in the exposure and development process has a process edge structure.

Embodiment 2

[0035] like figure 1 As shown, this embodiment provides a PCB board, which is composed of a PCB graphic area 101 and a process edge 102 .

[0036] Among them, the width of the process side is 50 mm, and it is composed of four processing parts connected end to end. The processing part has a copper foil layer, and five air guide grooves with a width of 2 cm are arranged on the copper foil layer of the processing part.

[0037] The preparation method is as follows: the copper clad laminate is sequentially cut, drilled, copper plated, exposed and developed, etched and washed, browned, laminated, pressed, and the outer layer PCB pattern is made to obtain the PCB board.

[0038] Wherein, the film pattern used in the exposure and development process has a process edge structure.

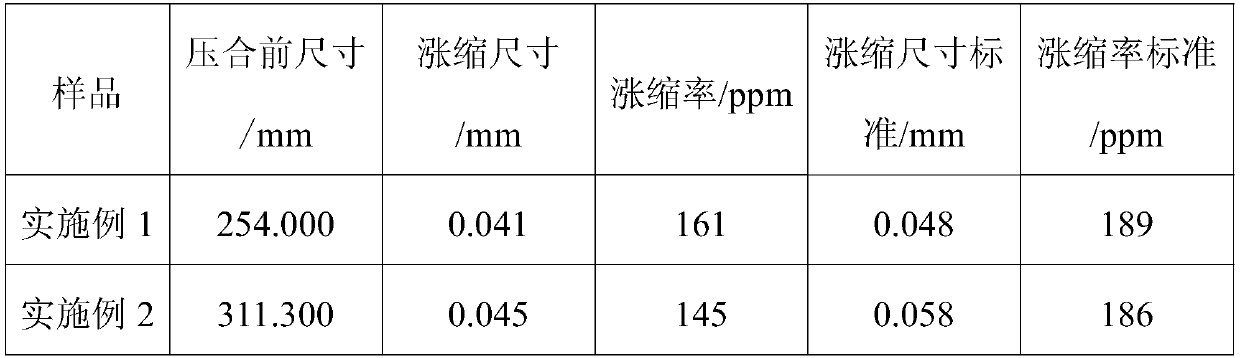

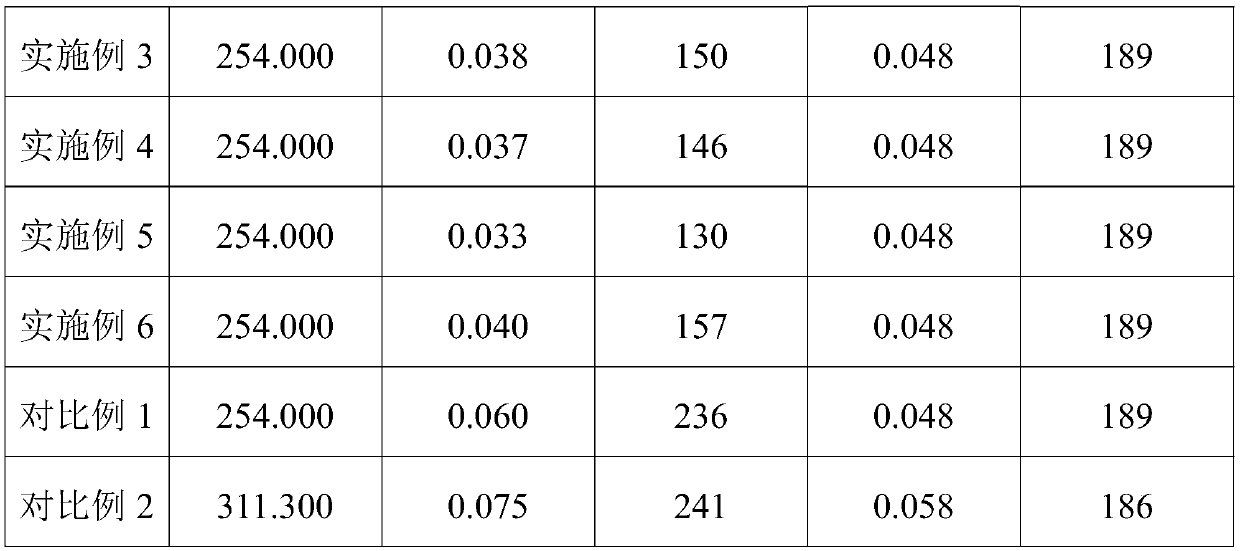

[0039] During the preparation process of the PCB board prepared above, the film pattern has a process edge structure, so the copper foil layer in the process edge is retained during the etching and washing...

Embodiment 3-5

[0041] The only difference from Embodiment 1 is that in this embodiment, the width of the process side is 20mm (Example 3), 25mm (Example 4), and 40mm (Example 5).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com