A kind of graphene oxide airgel, reduced graphene oxide airgel and its preparation method and application

A graphene airgel and graphene technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of complex process, difficulty in large-scale production, long preparation cycle, etc., and achieve high compression resilience, Effect that contributes to the dispersion of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

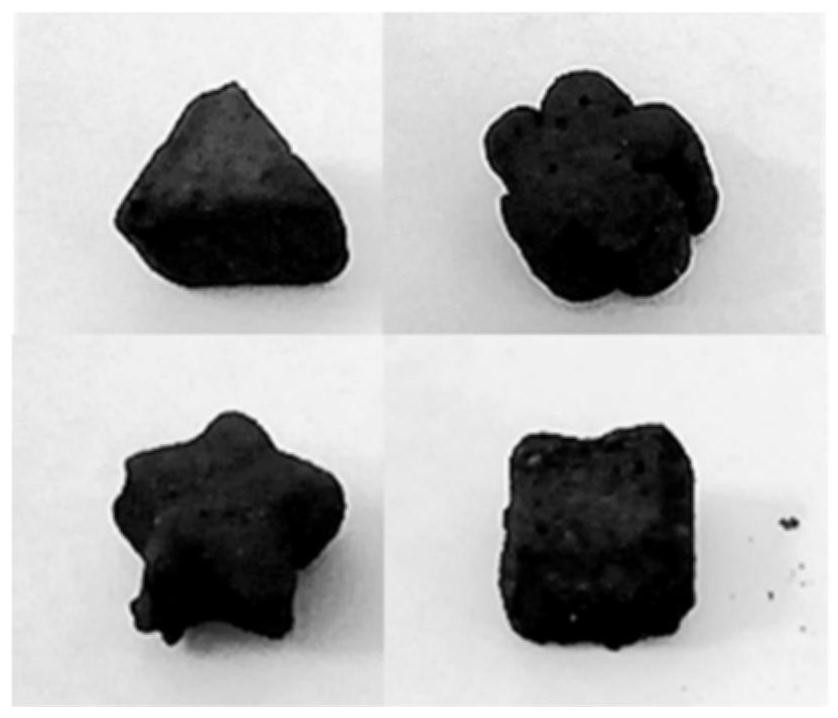

Image

Examples

Embodiment 1

[0076] (1) prepare graphene oxide:

[0077] Prepare graphene oxide by improving the Hummers method: Pour 2g of natural graphite, 120mL of concentrated sulfuric acid and 6g of potassium permanganate into a 250mL three-neck flask, place in an ice-water bath, and stir for 2h below 4°C; raise the temperature of the system to 50°C ℃, heat preservation reaction for 6 hours; after the reaction, add 240mL distilled water and 2-5mL hydrogen peroxide, continue to stir for 30min, then perform centrifugal washing to remove excess acid and impurities to obtain a graphene oxide suspension, and place it in a 4℃ refrigerator for later use , the carbon to oxygen ratio of graphene oxide is 0.96.

[0078] (2) Preparation of dual-electricity chitin nanofibers:

[0079] First, mix 10g of chitin powder with 200mL of 35% sodium hydroxide, stir and heat at 90°C for 1 hour, wash and remove the sodium hydroxide with ethanol, and dry to obtain deacetylated chitin powder. Utilize the titration method t...

Embodiment 2

[0087] (1) prepare graphene oxide: with embodiment 1;

[0088] (2) Preparation of dual-electricity chitin nanofibers: same as Example 1;

[0089] (3) Preparation of a suspension of graphene oxide-chitin nanofiber hybrid particles: same as Example 1;

[0090] (4) prepare graphene oxide airgel: with embodiment 1;

[0091] (5) Preparation of reduced graphene oxide airgel:

[0092] The graphene oxide airgel obtained in step (4) was thermally reduced at 800° C. for 1 h to obtain a reduced graphene oxide airgel with a density of 2.193 mg / cm 3 .

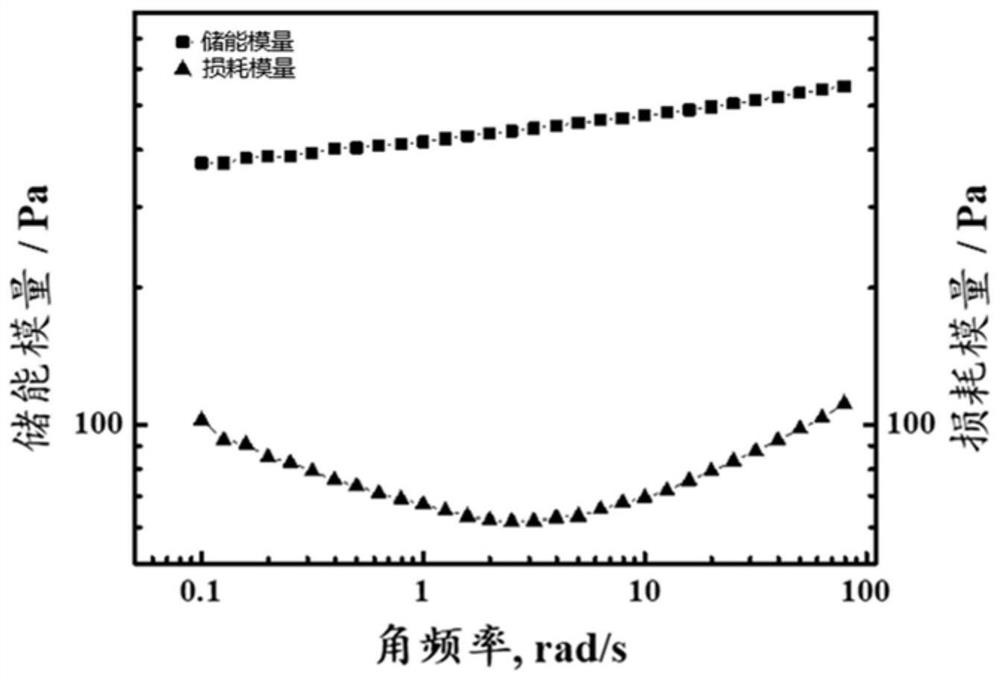

[0093] Thermal reduction treatment can reduce the defects of graphene oxide airgel: there are a large number of oxygen-containing groups such as epoxy groups, carboxyl groups, hydroxyl groups, etc. on the edge and surface of graphene oxide. During the thermal reduction step, these oxygen-containing groups will The removal begins to occur, so that the graphene oxide sp 2 The structural reconstruction improves the properties of the reduc...

Embodiment 3

[0095] Same as Example 1, the difference is that the mass ratio of graphene oxide to double-electric chitin nanofibers is changed to 99:1.

[0096] The obtained graphene oxide airgel has a density of 6.42 mg / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com