Method for assembling a water pump

A technology of water pumps and pump wheels, which is applied in the field of assembling water pumps and can solve problems such as loss of rare earth metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

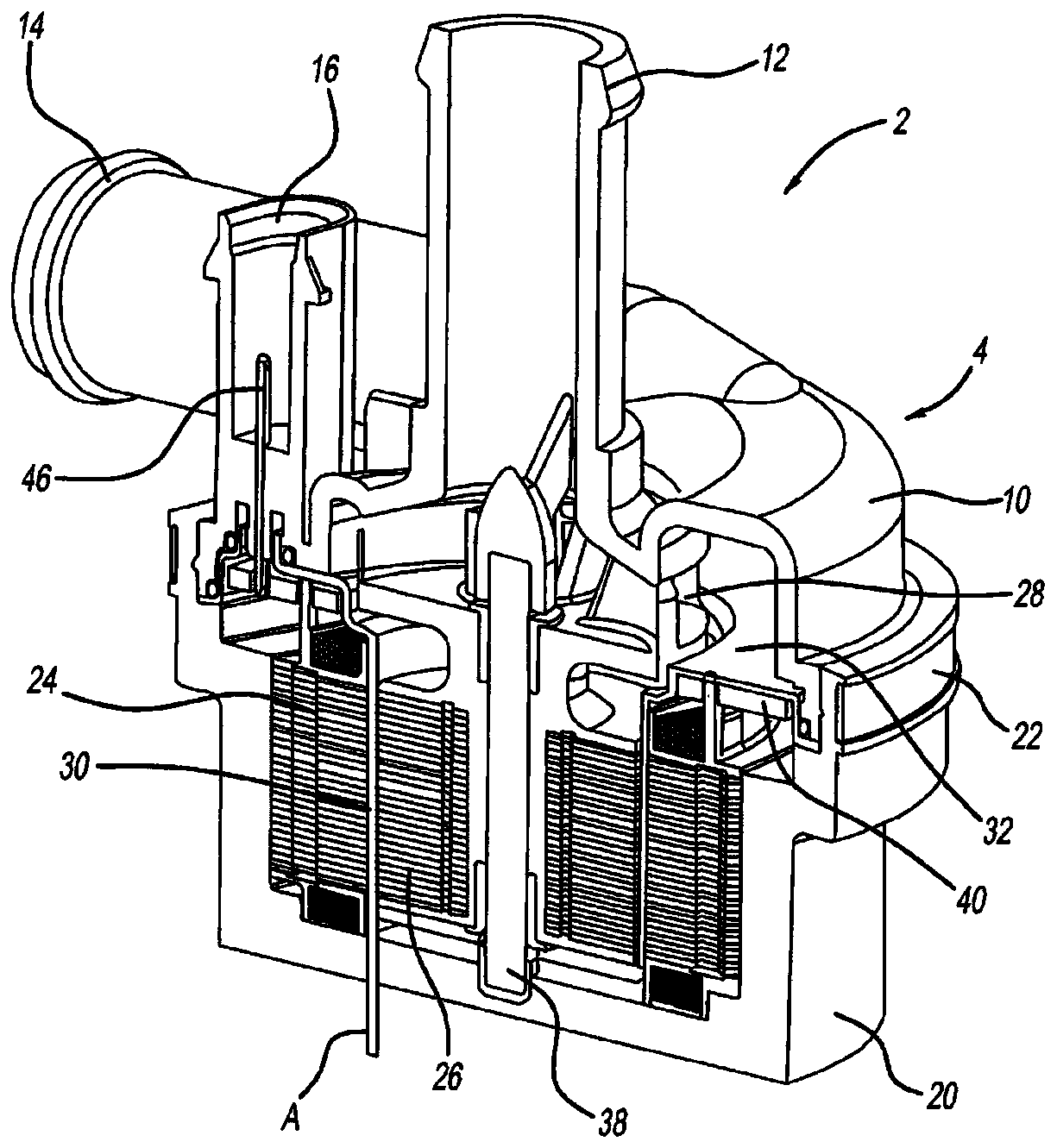

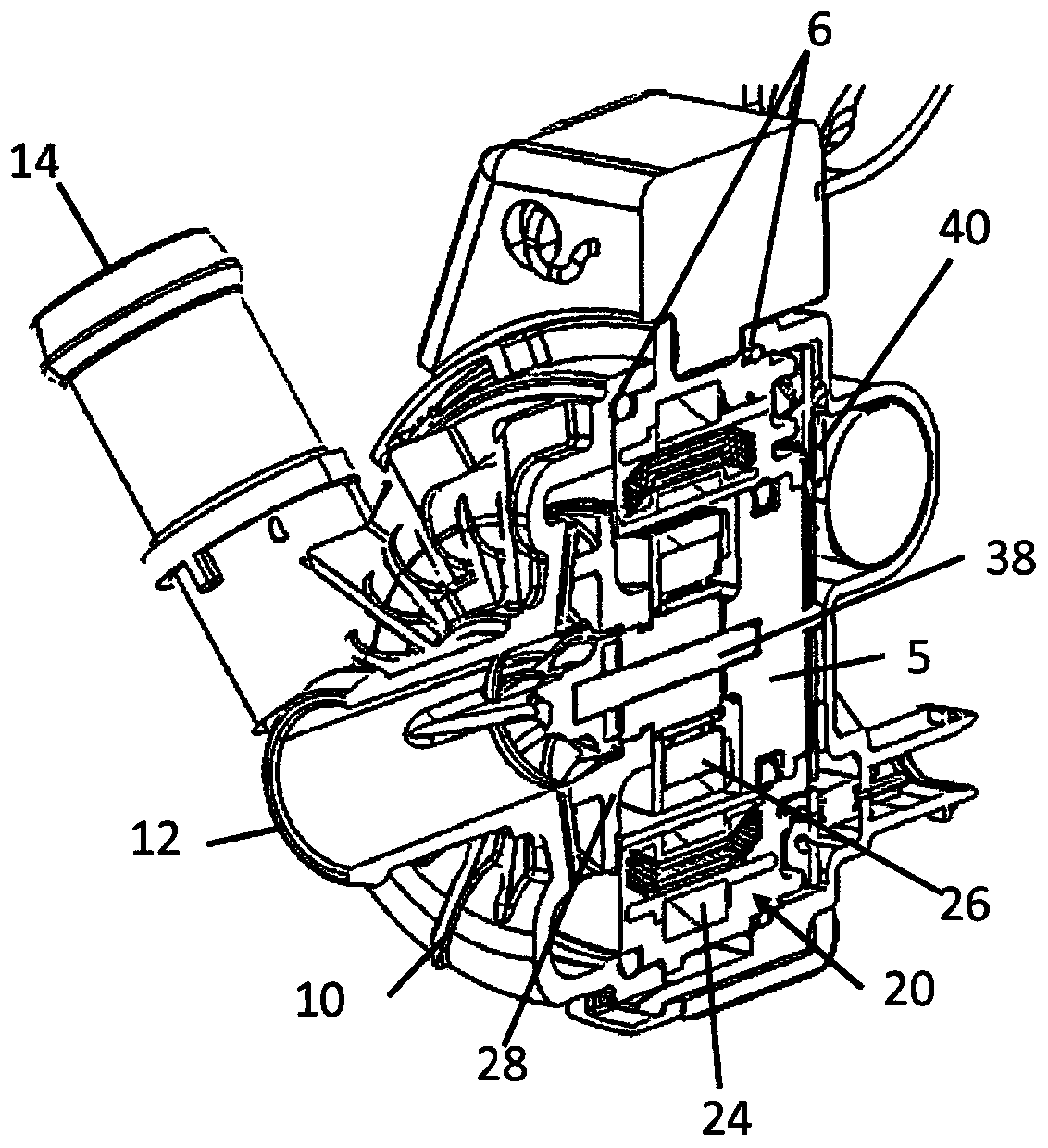

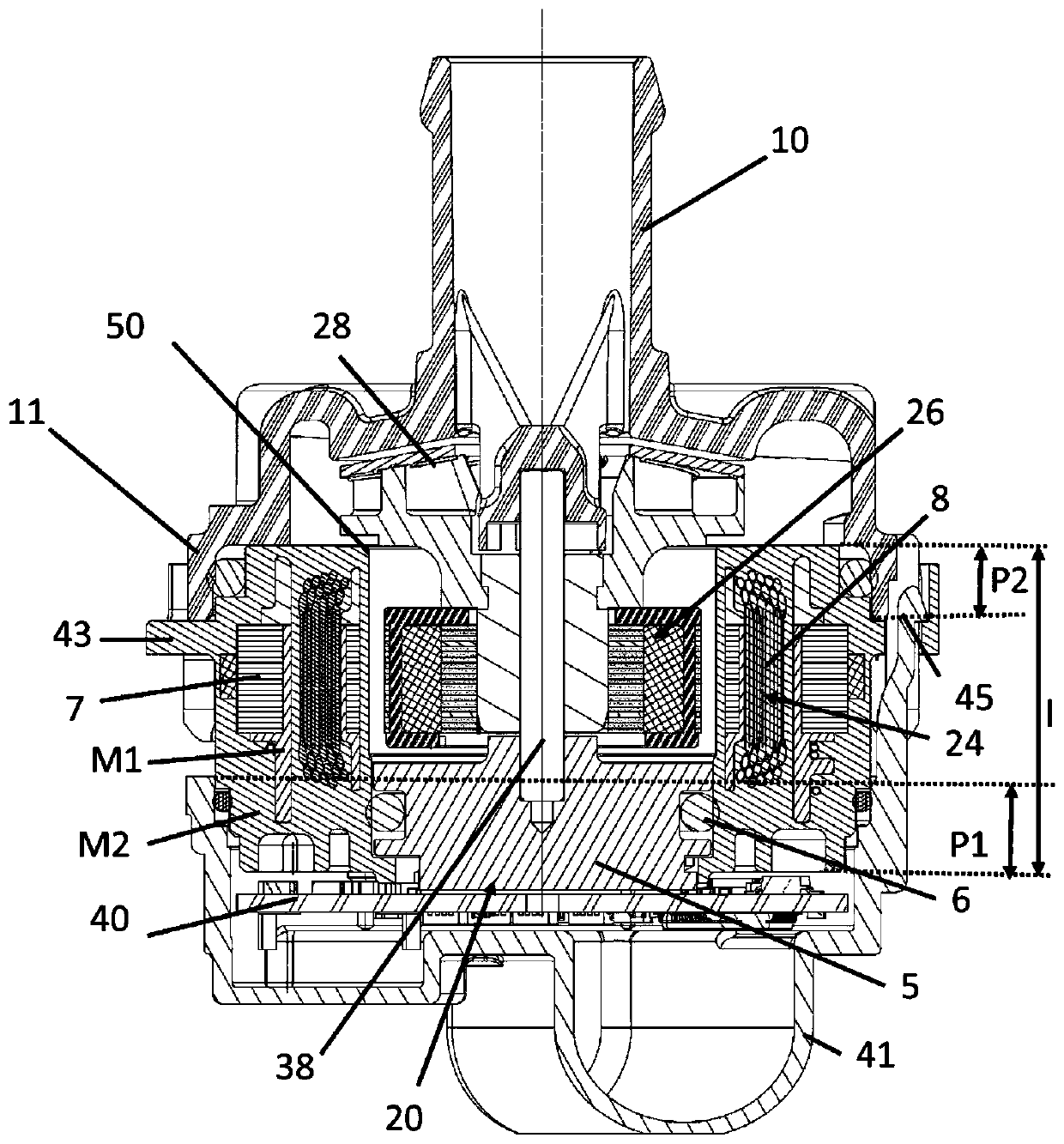

[0017] The water pump 2 comprises a screw housing 10 , a collar 20 and a band 22 which fixes the collar 20 and the screw housing 10 . The spiral housing 10 includes an inlet 12 and an outlet 14 . The screw housing includes current supply terminals 16 . The spiral housing 10 is connected to a collar 20 by means of a strap 22 and forms a cover 4 which surrounds the inner components and encloses the current supply connection 16 for accommodating a current supply line 46 . The internal components of the housingless water pump 2 include the stator 24 which is pressed into the collar 20 . A stator 24 surrounds a rotor 26 . The rotor 26 is separated from the stator 24 by a wet bush. The rotor 26 and the stator 24 are separated by a distance (A) by a magnetic air gap. Wet liner 30 prevents fluid from contacting stator 24 . The rotor 26 includes a shaft 38 and an impeller 28 for moving the fluid as it enters through the inlet 12 . The impeller 28 moves fluid through the outlet 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com