Laminator for sandwich ham sausages

A sausage laminator and ham technology, which is applied in the field of sandwich ham sausage laminators, can solve the problems of inconsistent appearance, slow artificial lamination efficiency, and less processing at one time, and achieves simple structure, high production efficiency and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

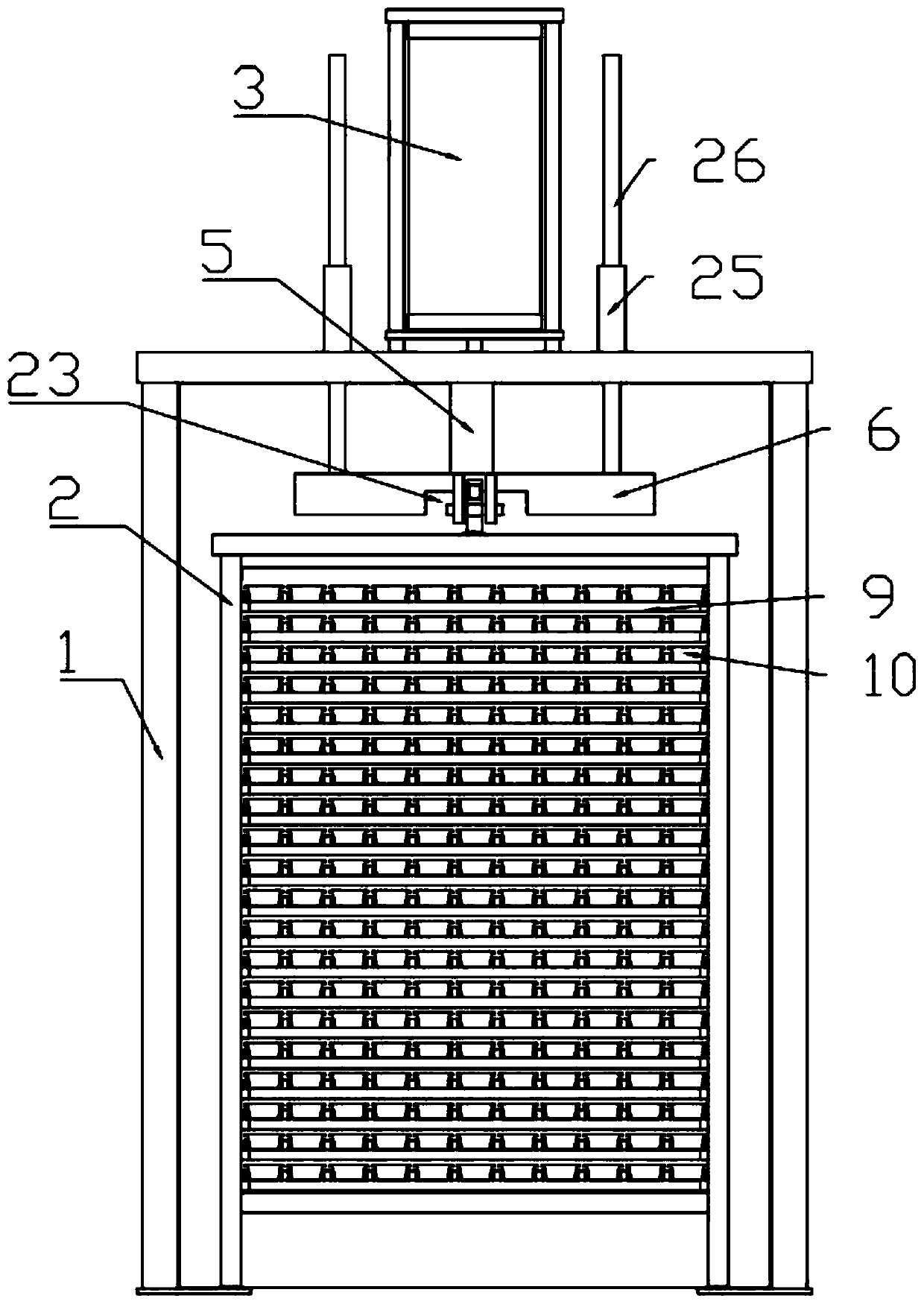

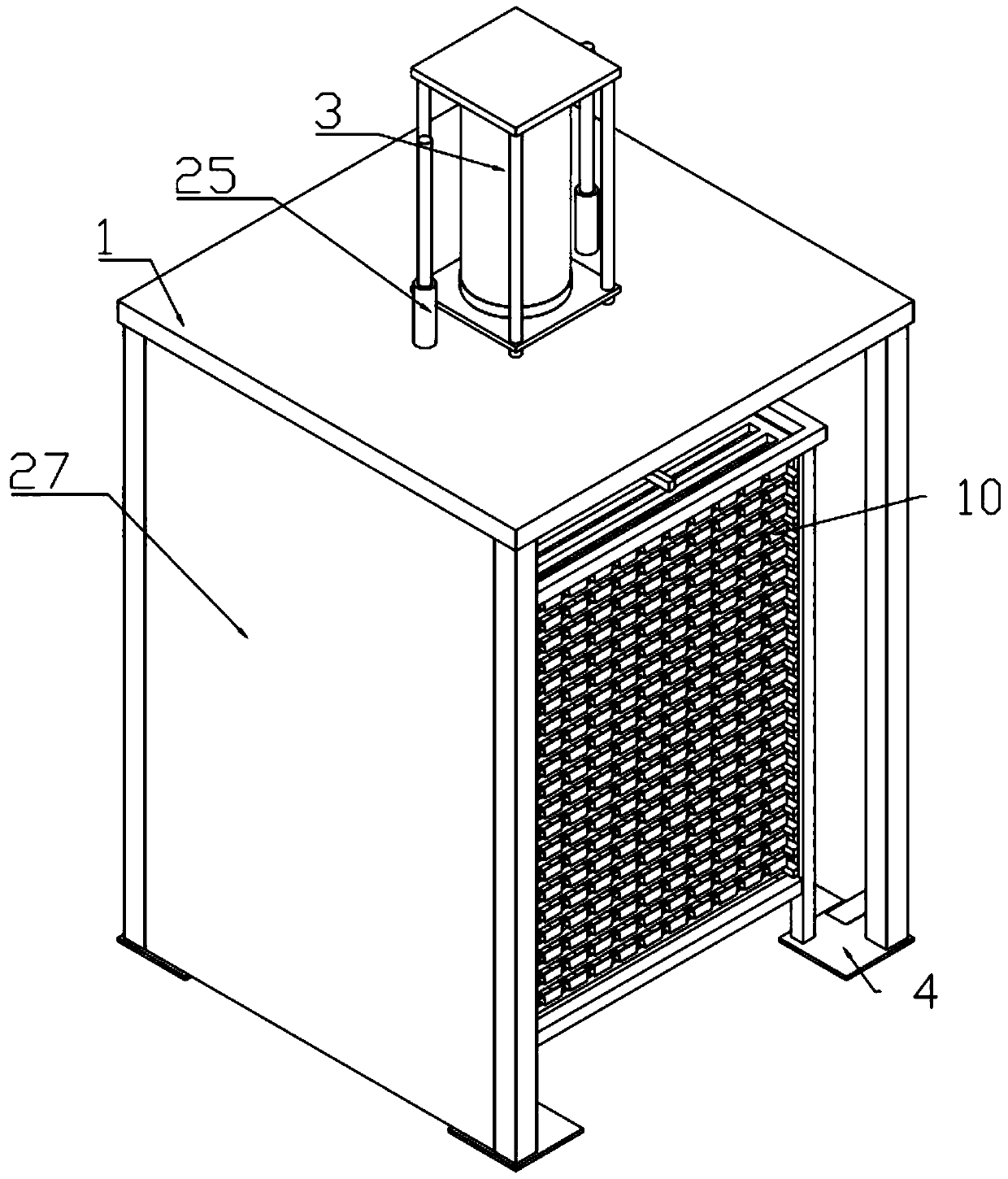

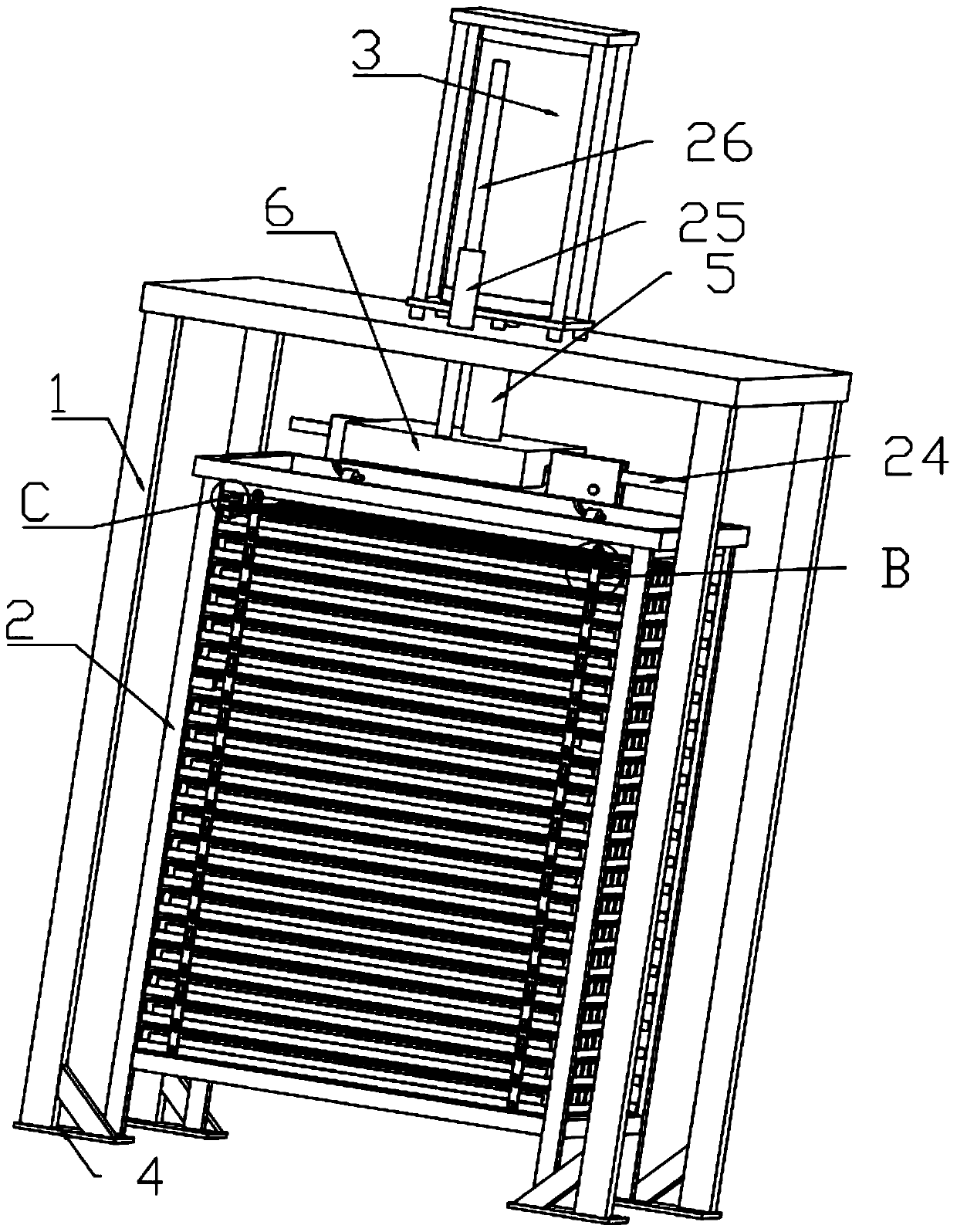

[0025] The following is a detailed description of the sandwich ham sausage film pressing machine of the present invention with reference to the accompanying drawings.

[0026] Attached Figure 1-9 , A sandwich ham sausage film pressing machine, comprising a frame 1, a support frame 2, a pneumatic cylinder 3 and a partition frame device. The lower end of the frame 1 is provided with a bottom plate 4, and the support frame 2 is arranged on the bottom plate 4, The pneumatic cylinder 3 is arranged at the upper end of the frame 1, the partition frame device is arranged in the support frame 2, and the partition frame device and the support frame 2 are in sliding fit;

[0027] The lower end of the pneumatic cylinder 3 is provided with a pneumatic rod 5, the pneumatic rod 5 passes through the frame 1 and extends into the frame 1, and one end of the pneumatic rod 5 in the frame 1 is provided with a pressure plate 6, and the pressure plate 6 is symmetrical With suspension device;

[0028] Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap