TDI macromolecular gel decontaminating agent

A molecular gel decontaminant, D230 technology, which is applied in the field of post-treatment of dangerous chemical products, can solve the problems of secondary pollution of decontamination products, large dosage of chemicals, long disposal time, etc., and achieves convenient follow-up treatment and fast response speed , the effect of rapid recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

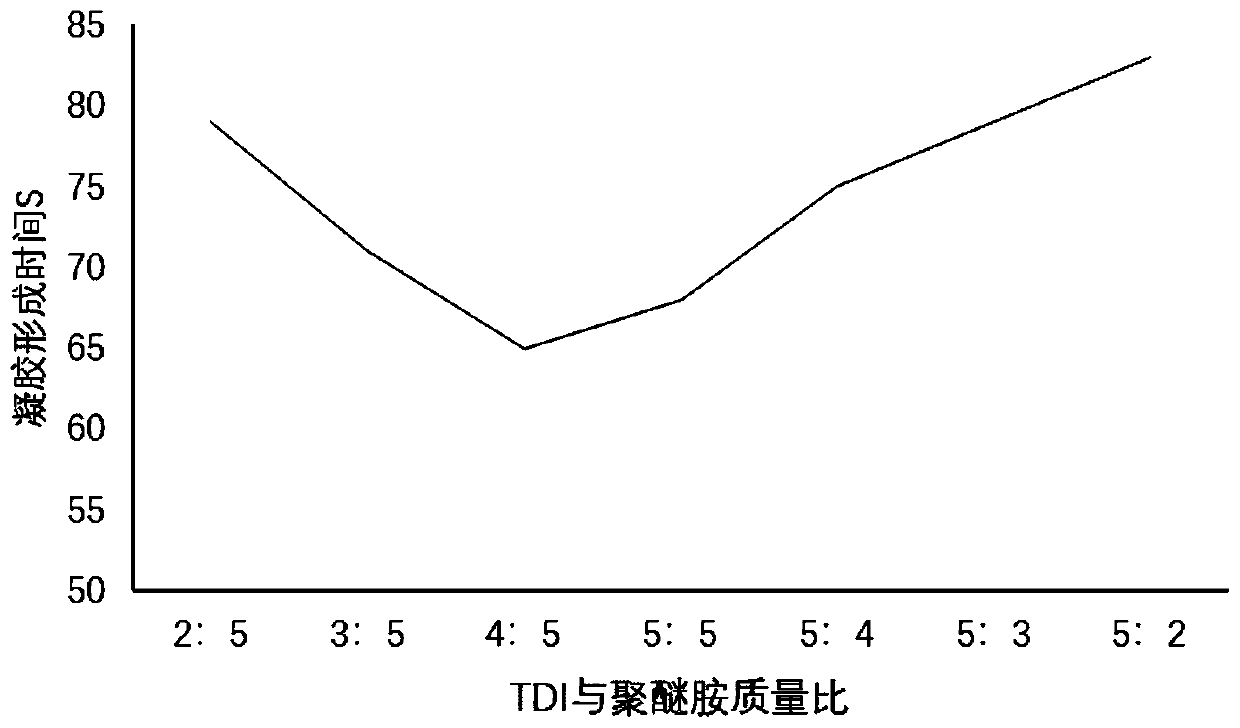

[0023] Embodiment 1 Toluene diisocyanate and polyether amine dosage ratio optimization

[0024] For the configuration of TDI macromolecular gel decontaminant, take 15g of isopropanol, 90g of the total mass of toluene diisocyanate and polyetheramine D230, and set the gradient of the dosage ratio of toluene diisocyanate and polyetheramine D230 to 2:5, 3:5 , 4:5, 5:5, 5:4, 5:3, 5:2; Prepare 700g of toluene to be decontaminated, and put it in a container with a surface area of 0.2 square meters, and set up 7 containers in total.

[0025] Mix polyetheramine D230 and isopropanol evenly and sprinkle it evenly on the surface of the container, then sprinkle toluene diisocyanate evenly on the surface of the container, start timing, when the mixture in the container appears as figure 1 When the gel state is shown, stop timing and calculate the time (s) for gel formation.

[0026] Measurement results such as figure 2 As shown, when the mass ratio of toluene diisocyanate and polyether...

Embodiment 2

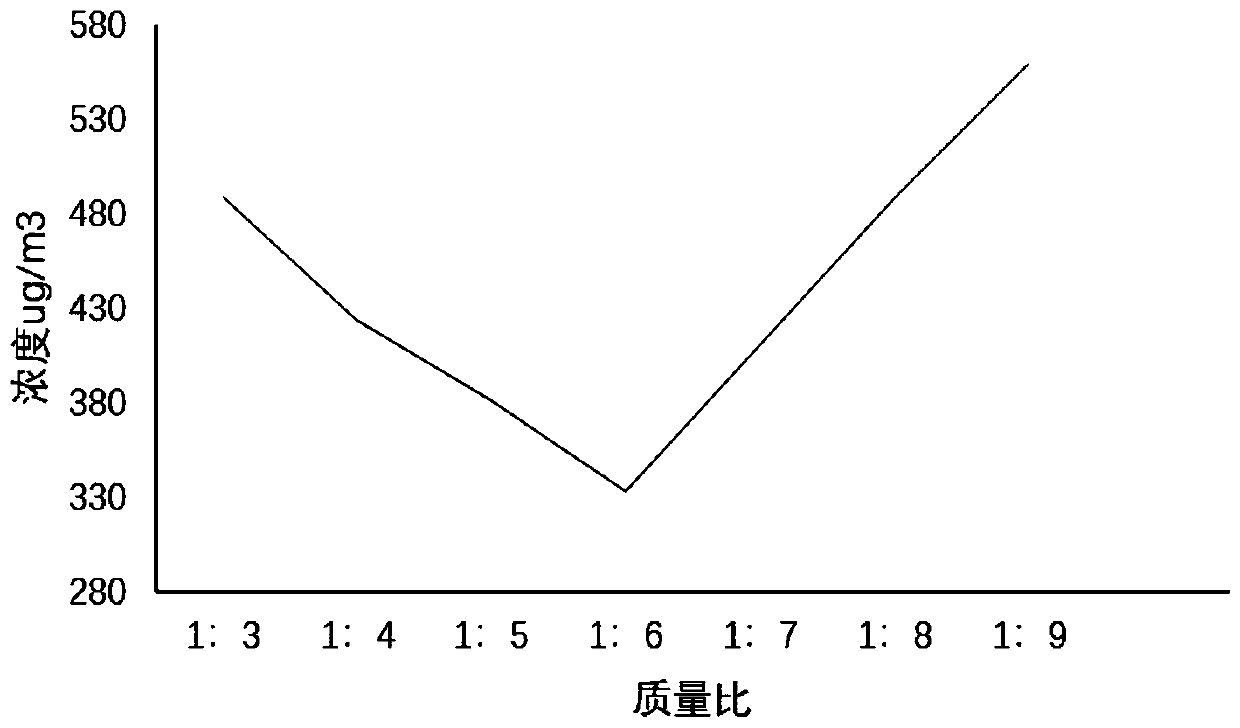

[0027] Example 2 Optimization of the total mass ratio of isopropanol to toluene diisocyanate and polyetheramine D230

[0028] Isopropanol is used as a dispersant, the amount of addition will affect the viscosity, mechanical properties and encapsulation rate of the final gel, and will eventually affect the volatilization of toluene in the gel.

[0029] The configuration of TDI macromolecular gel decontamination agent, the total amount is 100g, the dosage ratio of toluene diisocyanate and polyetheramine D230 is 4:5, the mass ratio of isopropanol to the total mass of toluene diisocyanate and polyetheramine D230, Set the gradient to 1:3, 1:4, 1:5, 1:6, 1:7, 1:8, 1:9; prepare 1000g of toluene to be decontaminated, and place it in a container with a surface area of 0.2 square meters. 7 containers.

[0030] Mix polyetheramine D230 and isopropanol evenly and sprinkle it evenly on the surface of the container, and then sprinkle toluene diisocyanate evenly on the surface of the conta...

Embodiment 3

[0034] The optimum amount optimization of embodiment 3 gel decontamination agent

[0035] For the configuration of TDI macromolecular gel decontamination agent, take 15g of isopropanol, 40g of toluene diisocyanate, 50g of polyetheramine D230, and 50g of polyetheramine D230 in isopropanol; prepare respectively 2100g of toluene to be decontaminated (equivalent to dosage is 5% of toluene mass), 1312.5g (8%), 1050g (10%), 875g (12%), 700g (15%), 583.3g (18%), 525g (20%) are placed on the surface area In a container of 0.2 square meters, a total of 8 containers are set.

[0036] Mix polyetheramine D230 and isopropanol evenly and sprinkle it evenly on the surface of the container, and then sprinkle toluene diisocyanate evenly on the surface of the container, when the mixture in the container appears as figure 1 When the gel state is shown, the gel is formed.

[0037] After the gel was formed, the detection method as in Example 2 was used to detect the volatilization of toluene, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com