Phase-change temperature-regulating microcapsule, preparation method and application thereof

A technology of microcapsules and temperature regulation, applied in the field of materials, can solve the problems of mechanical properties of composite fibers affecting spinning performance, easy clogging, poor phase change performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also provides a preparation method of the above-mentioned phase-change thermoregulation microcapsules, comprising the following steps:

[0059] adding ethylenediamine to distilled water to obtain an ethylenediamine solution, adding sodium lauryl sulfate to the ethylenediamine solution, and heating to obtain an aqueous solution of ethylenediamine and sodium lauryl sulfate;

[0060] The paraffin wax is slightly heated until it melts, the aqueous solution of ethylenediamine and sodium lauryl sulfate is placed under high shear conditions, and the melted paraffin wax and toluene-2,4-diisocyanate are added rapidly, and emulsified Liquid, emulsified, emulsified to obtain a stable dispersed emulsion;

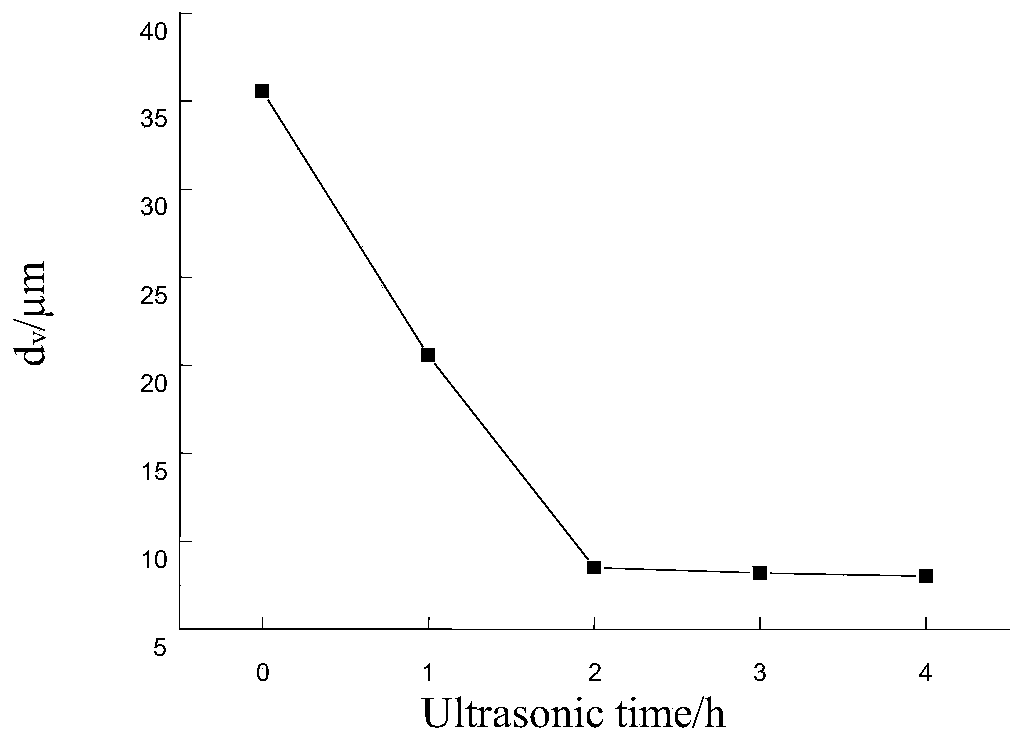

[0061] Under the condition of stirring and refluxing, the emulsion is ultrasonically shaken and reacted. After the reaction is completed, it is suction filtered, washed and dried to obtain the phase-change temperature-regulating microcapsules.

[0062] As a...

Embodiment 1

[0081] A preparation method of the above-mentioned phase-change temperature-regulating microcapsules, comprising the following steps:

[0082] adding ethylenediamine to distilled water to obtain an ethylenediamine solution, adding sodium lauryl sulfate to the ethylenediamine solution, and heating to obtain an aqueous solution of ethylenediamine and sodium lauryl sulfate;

[0083]The paraffin wax is slightly heated until it melts, the aqueous solution of ethylenediamine and sodium lauryl sulfate is placed under high shear conditions, and the melted paraffin wax and toluene-2,4-diisocyanate are added rapidly, and emulsified Liquid, emulsified, emulsified to obtain a stable dispersed emulsion;

[0084] Under the condition of stirring and refluxing, the emulsion is ultrasonically shaken and reacted. After the reaction is completed, it is suction filtered, washed and dried to obtain the phase-change temperature-regulating microcapsules.

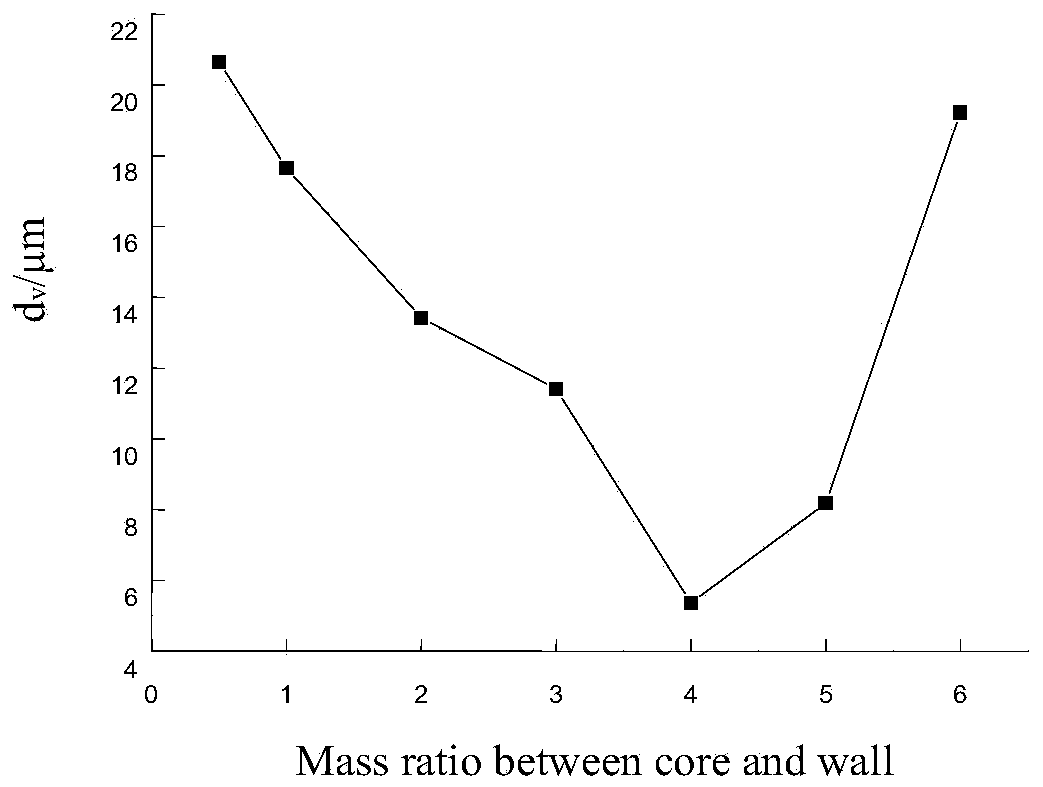

[0085] The mass ratio of the core material...

PUM

| Property | Measurement | Unit |

|---|---|---|

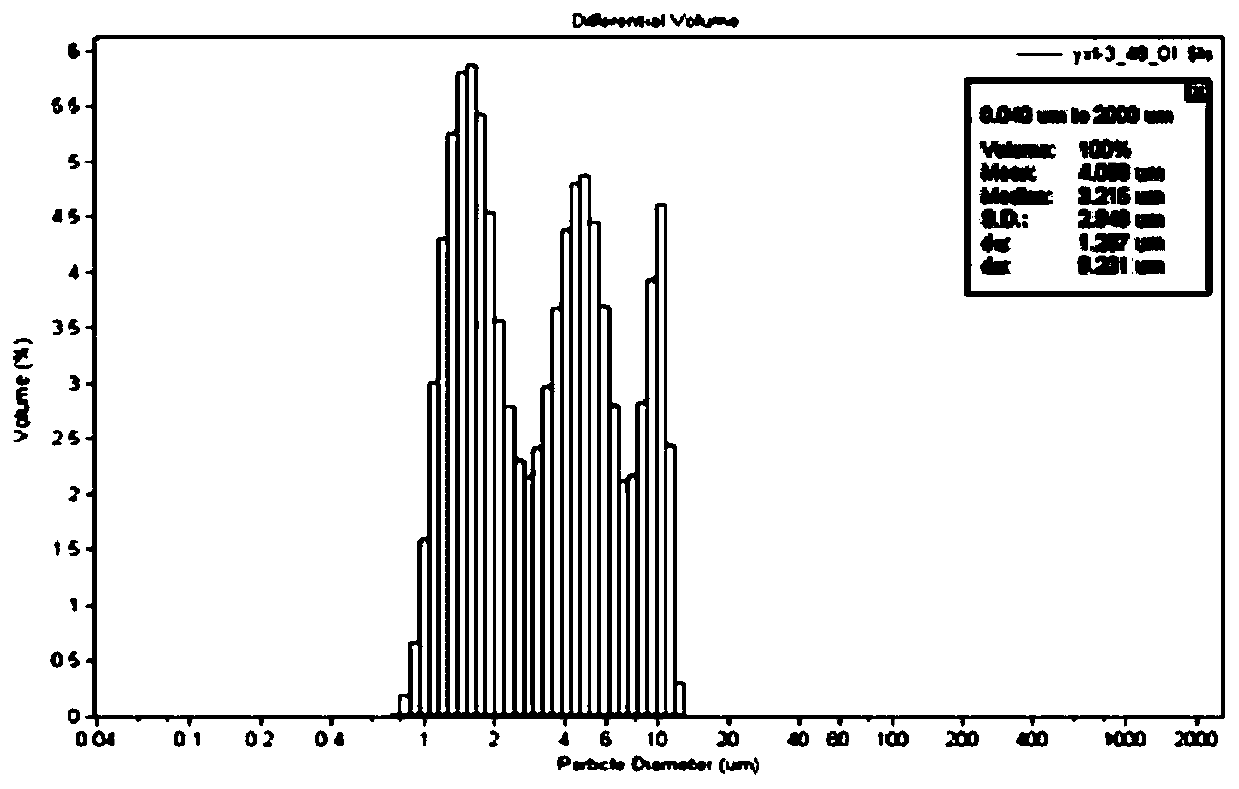

| Particle size | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap