Multi-angle in-pipe dredging device

A dredging device, multi-angle technology, applied in the direction of cleaning hollow objects, cleaning methods and appliances, fixed/solidified sludge treatment, etc., can solve the problems of pipeline wall damage, failure to be taken away in time, blockage, etc., and achieve crushing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

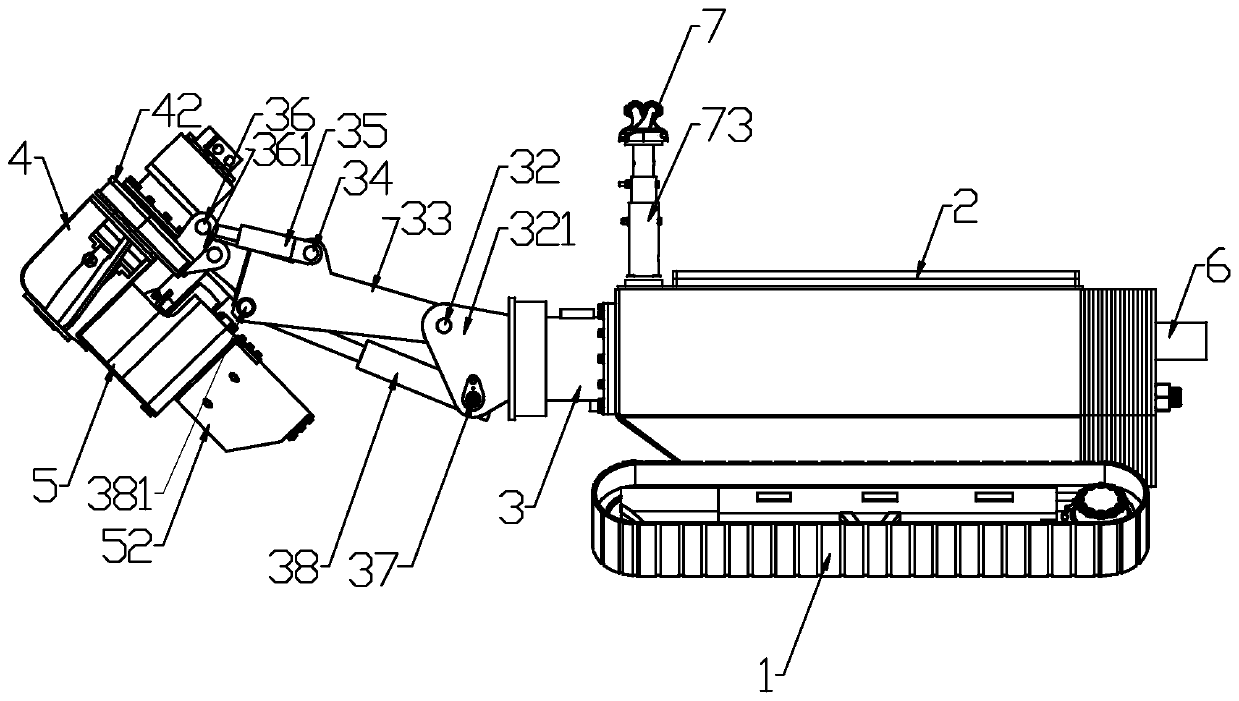

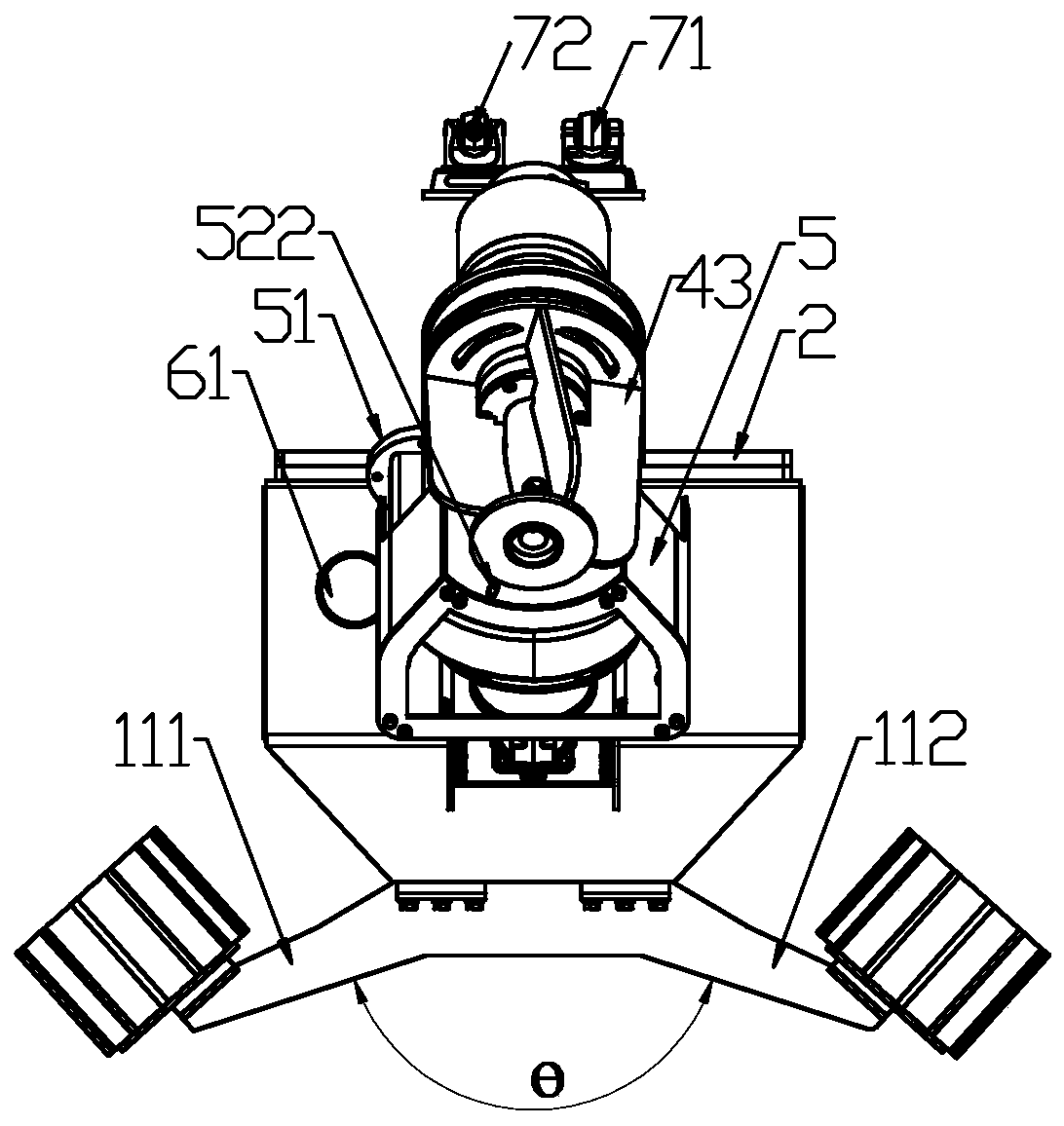

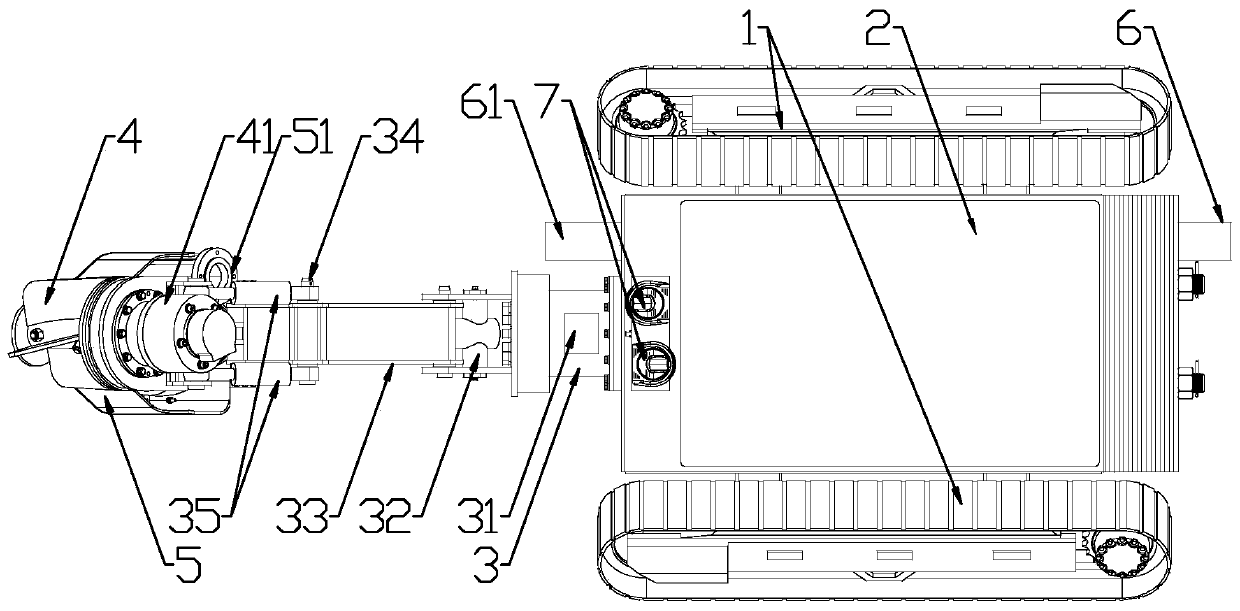

[0020] In this case, the multi-angle pipe dredging device, combined with figure 1 , figure 2 and image 3 , including walking wheel 1 (set according to use needs), main shaft 3, rotating gear 4, mud suction tank 5, mud discharge port 6, camera unit 7 (as a signal input part, which can be set according to use needs) and central control (Fig. not shown in ), the travel wheel 1 is connected with a travel drive (such as a motor, not shown in the figure), the main shaft 3 is located on the travel wheel 1, and is driven by the main shaft (such as a motor, etc., in the figure Not shown) to drive it to rotate (rotate itself, and drive the subsequent rotating gear 4 to rotate accordingly), a multi-stage telescopic arm is arranged between the main shaft 3 and the rotating gear 4, and each telescopic arm is driven by a telescopic arm (such as a cylinder, Hydraulic cylinders and other forms, not shown in the figure), are driven separately. The walking driver, main shaft driver, telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com