A Control Method for Reducing Transverse Thickness Difference of Hot-rolled Strip Steel

A technology of hot-rolled strip and control method, which is applied in the direction of rolling mill control device, rolling force/roll gap control, metal rolling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Utilize a kind of control method of reducing the lateral thickness difference of hot-rolled strip steel of the present invention, produce W20P, concrete control comprises:

[0064] ① Slab thickness:

[0065]

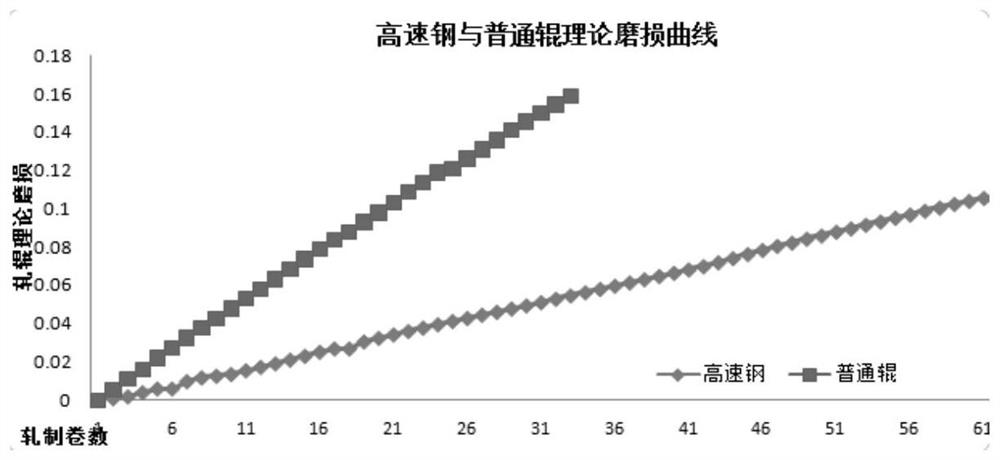

[0066] ②Finish-rolled high-speed steel configuration:

[0067] frame F5 F6 F7 material high speed steel high speed steel high speed steel

[0068] ③Work roll cooling water volume:

[0069] Variety frame F5 F6 F7 W20P amount of water 90% 90% 90%

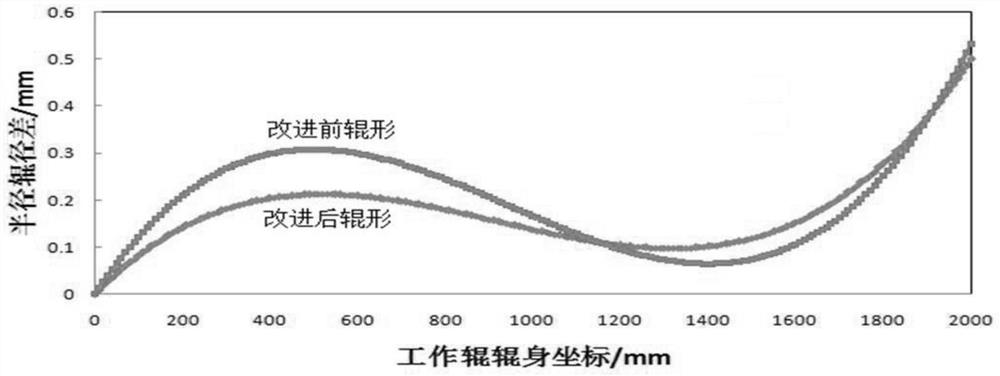

[0070] ④Work roll shape:

[0071] frame a1 a2 a3 F5 / F6 / F7 9.49688e-04 -1.3750e-06 5.0000e-10

[0072] ⑤Vertical roller pressure:

[0073]

[0074] ⑥Rolling oil parameters:

[0075] Variety frame F2 F3 F4 F5 F6 W20P oil quantity 40 40 40 45 45

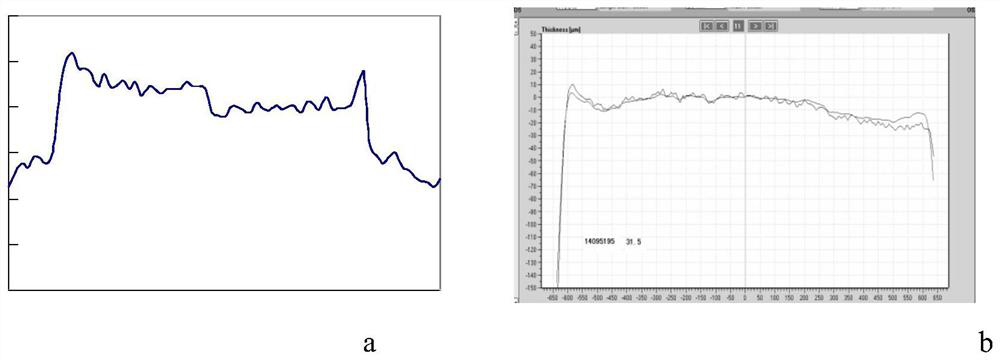

[0076] ⑦ Effect:

[0077]

Embodiment 2

[0079] Utilize a kind of control method of reducing the lateral thickness difference of hot-rolled strip steel of the present invention, produce W23P, concrete control comprises:

[0080] ① Slab thickness:

[0081]

[0082] ②Finish-rolled high-speed steel configuration:

[0083] frame F5 F6 F7 material high speed steel high speed steel high speed steel

[0084] ③Work roll cooling water volume:

[0085]

[0086]

[0087] ④Work roll shape:

[0088] frame a1 a2 a3 F5 / F6 / F7 9.49688e-04 -1.3750e-06 5.0000e-10

[0089] ⑤Vertical roller pressure:

[0090]

[0091] ⑥Rolling oil parameters:

[0092] Variety frame F2 F3 F4 F5 F6 W20P oil quantity 50 50 50 60 60

[0093] ⑦ Effect:

[0094]

Embodiment 3

[0096] Utilize a kind of control method of reducing the lateral thickness difference of hot-rolled steel strip of the present invention, produce W30P, specific control includes:

[0097] ① Slab thickness:

[0098]

[0099] ②Finish-rolled high-speed steel configuration:

[0100] frame F5 F6 F7 material high speed steel high speed steel high speed steel

[0101] ③Work roll cooling water volume:

[0102] Variety frame F5 F6 F7 W30P amount of water 90% 90% 90%

[0103] ④Work roll shape:

[0104] frame a1 a2 a3 F5 / F6 / F7 9.49688e-04 -1.3750e-06 5.0000e-10

[0105] ⑤Vertical roller pressure:

[0106]

[0107] ⑥Rolling oil parameters:

[0108] Variety frame F2 F3 F4 F5 F6 W20P oil quantity 50 50 50 60 60

[0109] ⑦ Effect:

[0110]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com