Method for configuring shape of supporting roll of four-high mill and shape of working roll thereof

A four-high mill and back-up roll technology, applied in the direction of rolls, metal rolling, manufacturing tools, etc., to reduce roll consumption, improve shape control accuracy, and reduce steel rolling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

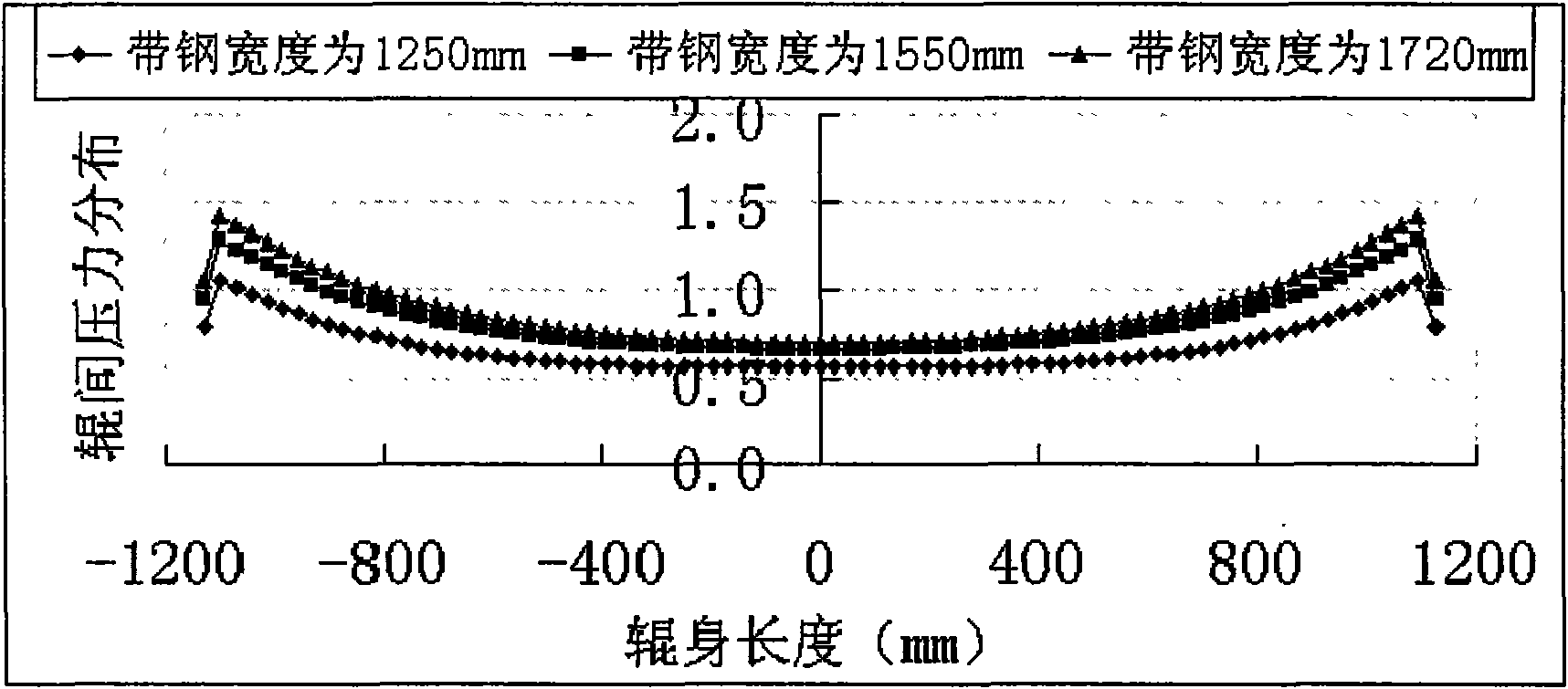

[0084] The 2160mm hot-rolled wide-band steel production line of Shougang Qiangang was put into operation at the end of 2006. During the production process in 2007, there were many times when the back-up rolls and work rolls on the rough rolling and finishing rolling units peeled off or Breakage leads to production accidents in which rolls are scrapped early during service, causing large economic losses. In 2008, after the smooth production, there were many accidents of roll surface peeling and roll breakage, especially the rough rolling R2 stand. Because there are a lot of camber feedback in the cold-rolled material, and there are shape defects such as waves and wedges, the hit rate of strip shape control is relatively low and needs to be further improved.

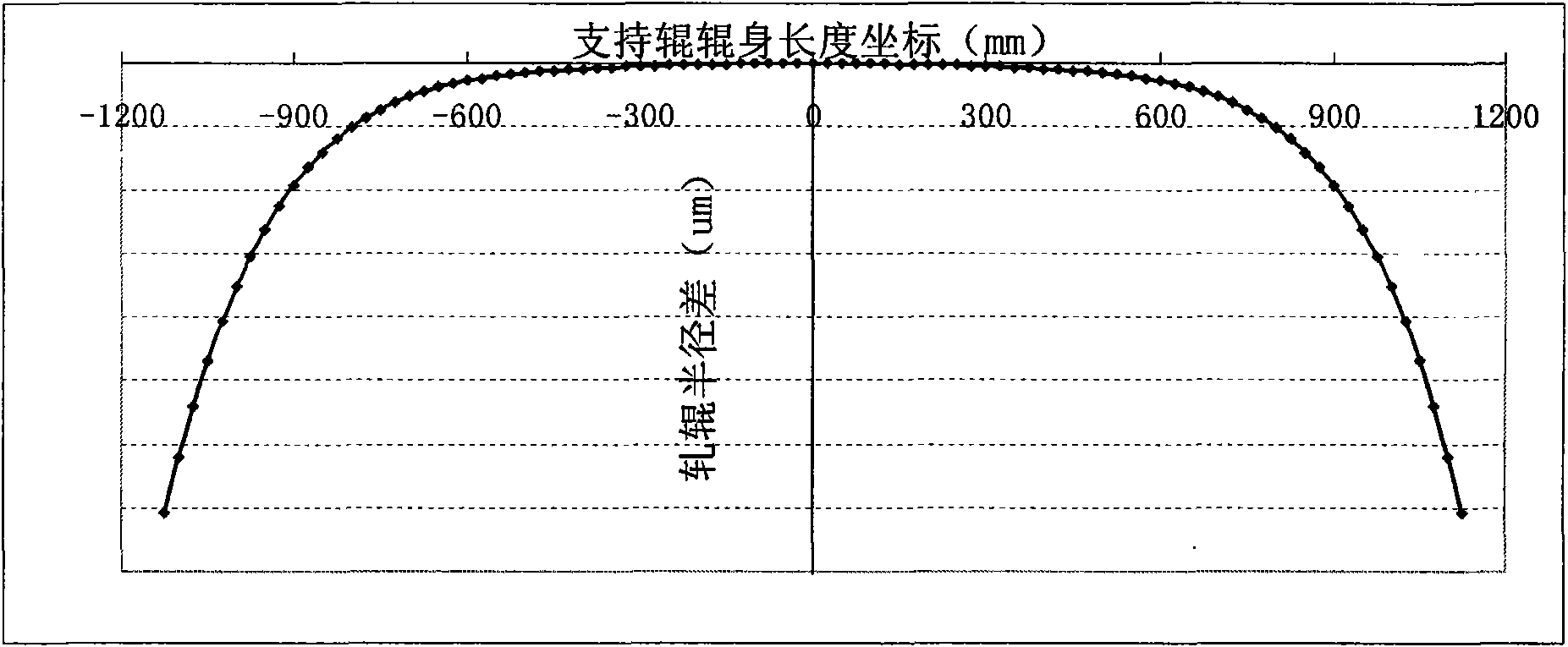

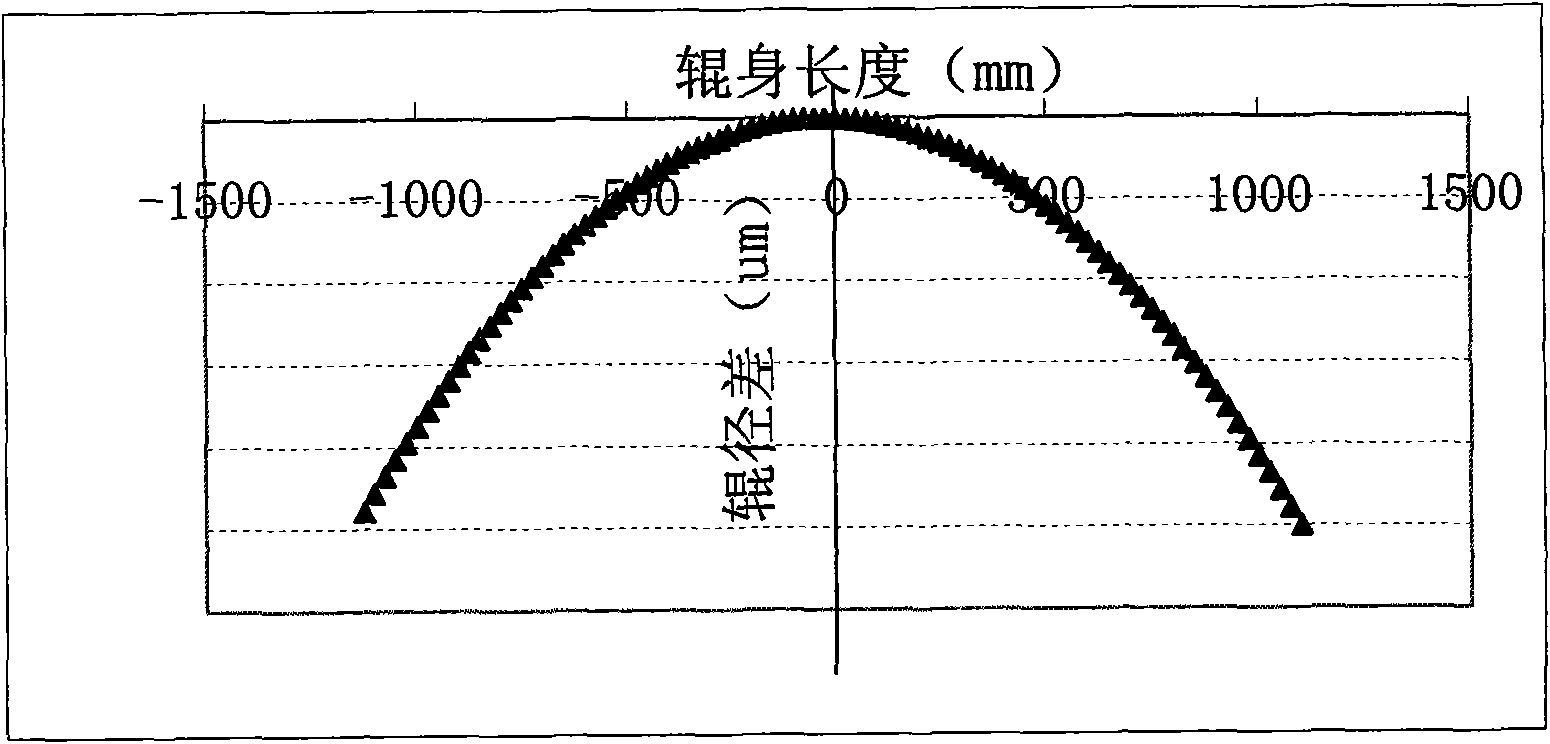

[0085] When designing the 2160mm hot-rolling unit of Qiangang in Shougang Company, the back-up roll did not adopt the roll shape, but the flat roll with edge chamfering method. There are generally three forms of chamferin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com