Composite geotextile and drainage reinforcing structure

A technology of composite geotextile and reinforcement structure, applied in the field of composite geotextile and drainage reinforcement structure, can solve the problems of low soil strength, fiber stripping, safety, etc., achieve high CBR bursting strength, low elongation at break, improve the use of effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

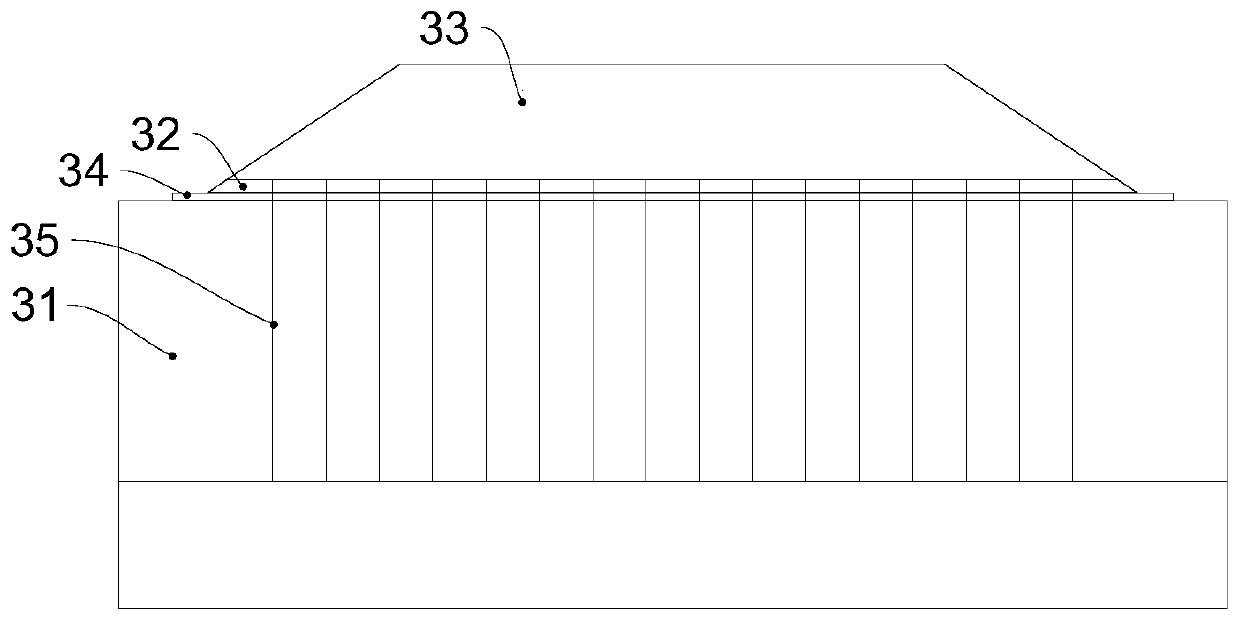

[0047] see image 3 , the drainage reinforcement structure of this embodiment is applied to embankment reinforcement and lateral drainage on soft ground. The bottom drainage of the embankment and the construction platform layer are generally made of coarse sand or gravel, and the drainage reinforcement structure of this embodiment can also be made of natural drainage materials such as medium sand or clay with poor drainage performance.

[0048] The drainage reinforcement structure includes a soft soil base 31, a construction platform layer 32, an embankment filler layer 33, a third drainage reinforcement layer 34 and a plurality of drainage channels 35, and the third drainage reinforcement layer 34 is made of composite geotextile as above. The construction platform layer 32 is arranged on the soft soil base layer 31, the third drainage reinforcement layer 34 is horizontally arranged between the construction platform layer 32 and the soft soil base layer 31, and the end of the ...

Embodiment 3

[0051] see Figure 4 , The drainage reinforcement structure of this embodiment is applied to the reinforcement and lateral drainage of steep slopes and earth walls.

[0052] The drainage reinforcement structure includes undisturbed soil 41, backfill soil 42, fourth drainage reinforcement layer 43, two fifth drainage reinforcement layers 44, multiple reinforcement fabric layers 45, multiple soil bags 46 and multiple sixth drainage reinforcement layers 47 , the fourth drainage reinforcement layer 43, the fifth drainage reinforcement layer 44 and the sixth drainage reinforcement layer 47 are all made of the above-mentioned composite geotextile.

[0053] The undisturbed soil 41 comprises a steep slope and a ground layer. The steep slope is obliquely arranged on the ground layer. The steep slope is provided with a first inclined surface 412 on the side of the bottom surface layer. The ground layer is provided with a first plane 411. The first plane 411 and the first inclined surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com