Novel automobile LED and laser headlamp electrical framework

An electrical structure and headlight technology, applied in the direction of headlights, light sources, circuit layout, etc., can solve the problems of high wiring harness cost, many wiring harness loops, long installation time, etc., to simplify plastic molds, save installation costs, and save materials. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

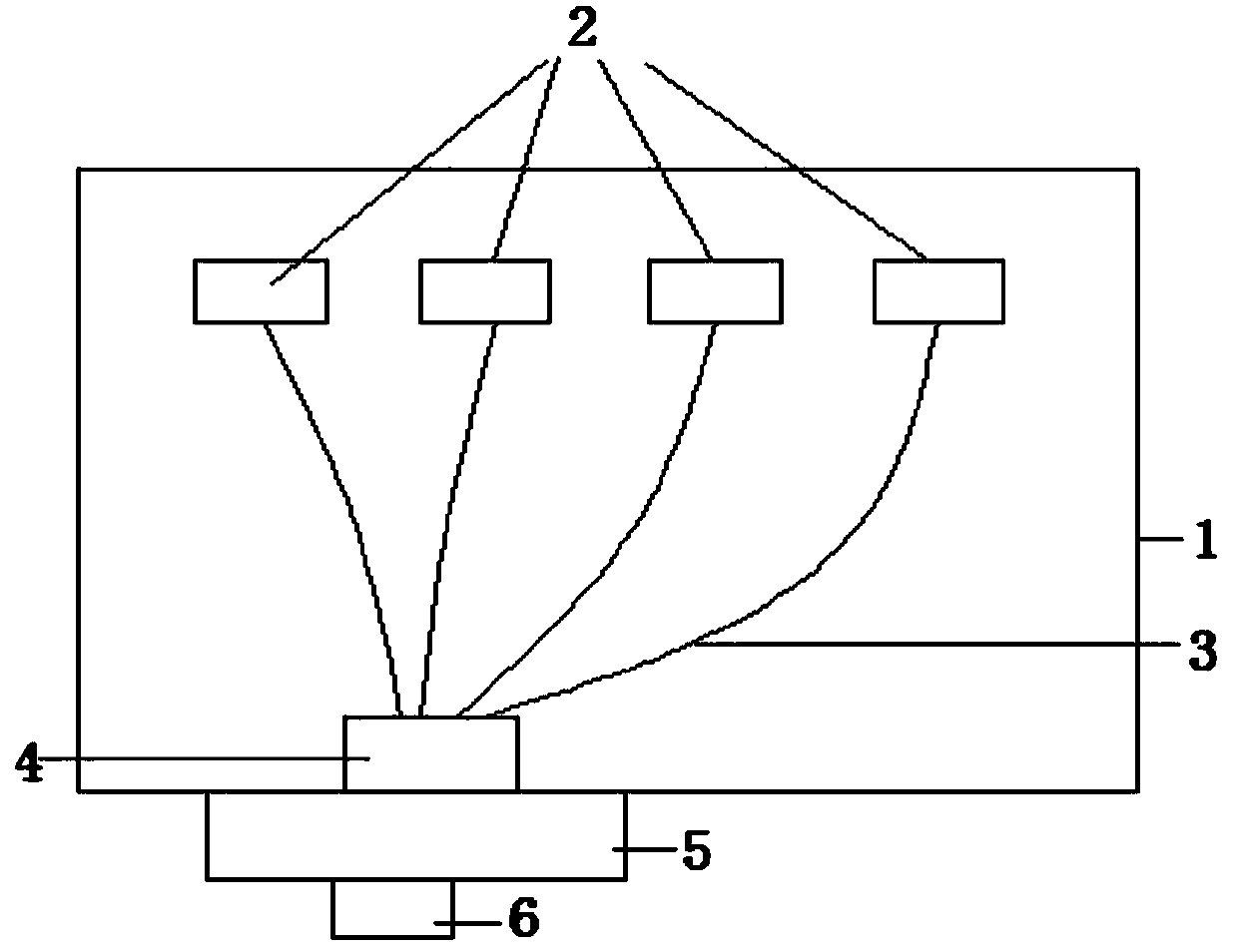

[0012] Such as figure 1 The electrical structure of a new type of automotive LED and laser headlight shown includes an automotive lamp body 1. A lamp panel 2 is installed inside the automotive lamp body 1, and the lamp panel 2 is connected to the lamp through a lamp harness 3. The controller internal connector 4 is installed on the vehicle light controller 5, and the vehicle light controller 5 is also directly equipped with a vehicle light to vehicle connector 6.

Embodiment 2

[0014] Such as figure 1 The electrical structure of a new type of automotive LED and laser headlight shown includes an automotive lamp body 1. A lamp panel 2 is installed inside the automotive lamp body 1, and the lamp panel 2 is connected to the lamp through a lamp harness 3. The controller internal connector 4 is installed on the vehicle light controller 5, and the vehicle light controller 5 is also directly equipped with a vehicle light to vehicle connector 6.

[0015] Preferably, the vehicle light-to-vehicle connector 6 is directly welded on the PCB of the vehicle light controller 5 .

[0016] Preferably, the vehicle light-to-vehicle connector 6 is externally connected to a headlight power supply, a communication information module, and left and right light identification signal lights.

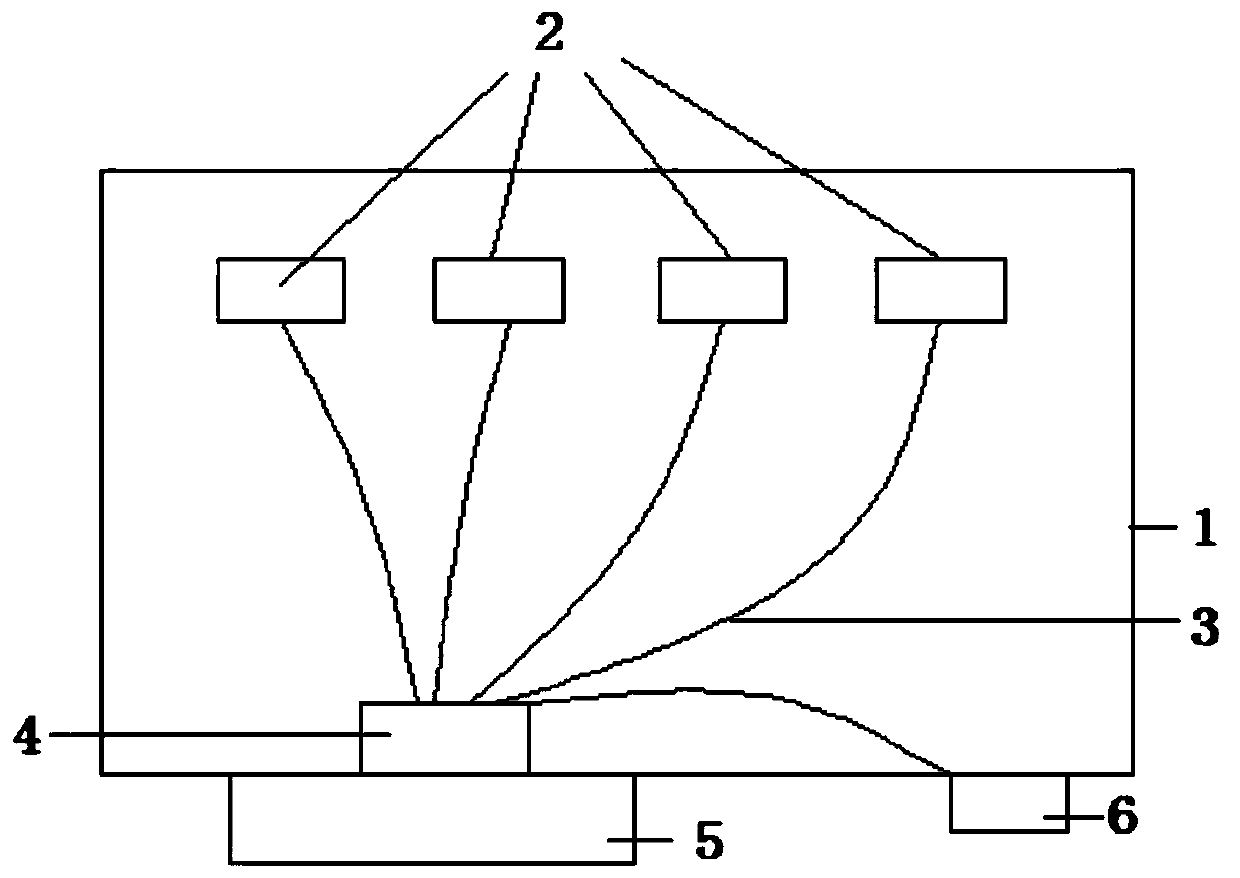

[0017] Process flow and working principle of the present invention are: as figure 2 In the electrical architecture of the existing automotive LED and laser headlights, the car light-to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com