Two-dimensional array low-pollution combustion device without traditional cyclone

A combustion device, two-dimensional array technology, applied in combustion chambers, combustion methods, combustion equipment, etc., can solve the problems of low pollutant emission levels, difficulty in achieving, and increase NOx pollutant emissions, so as to reduce nitrogen oxide emissions, Avoid the effect of local high temperature and local low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

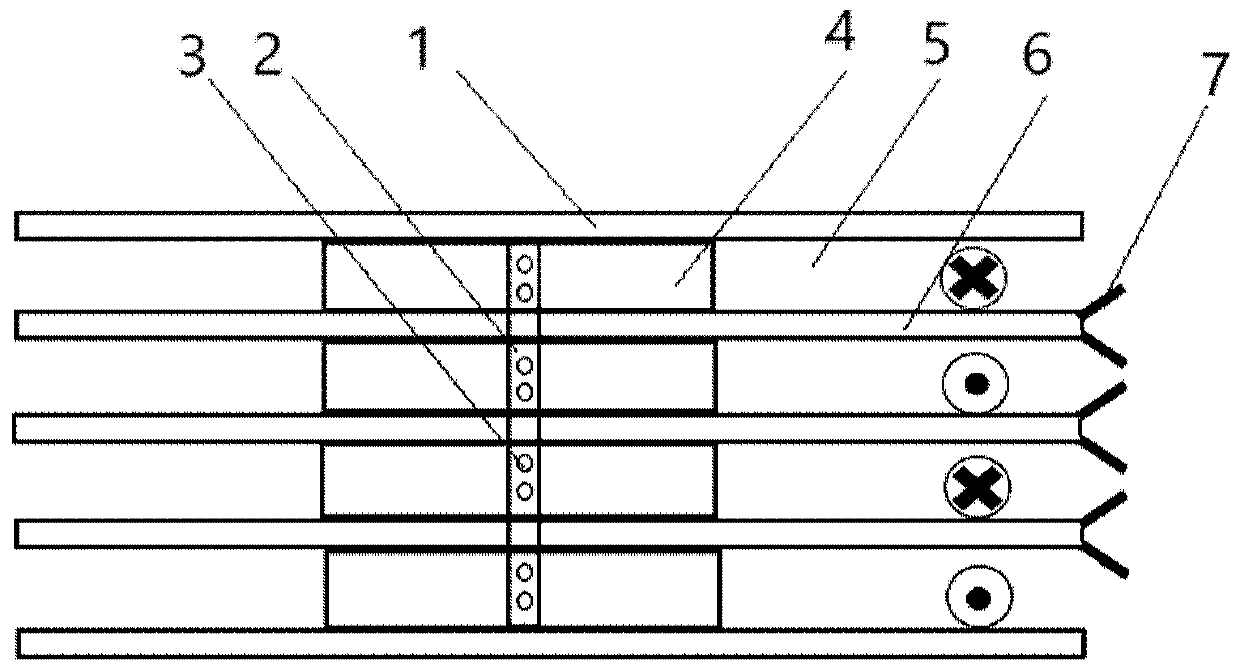

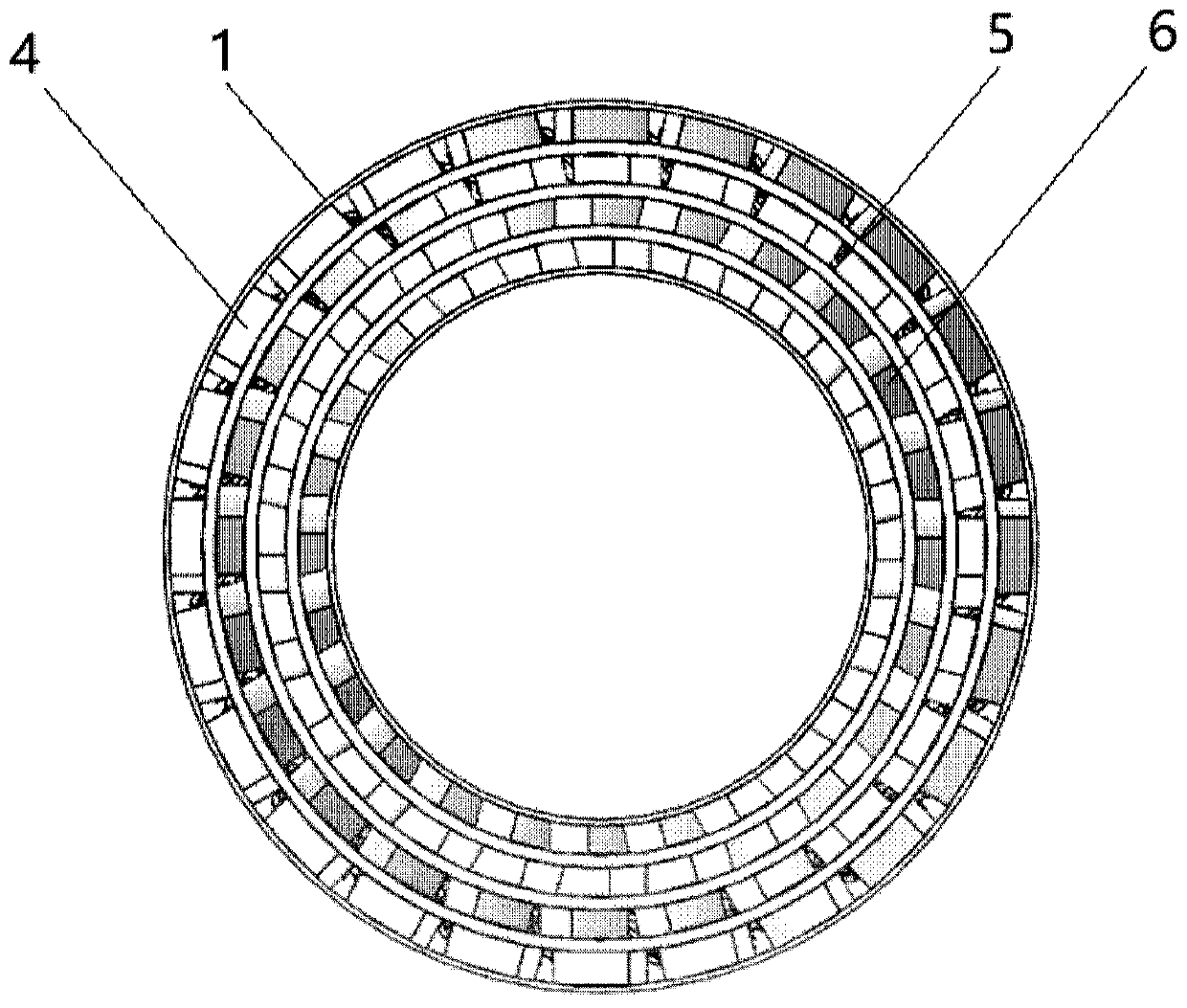

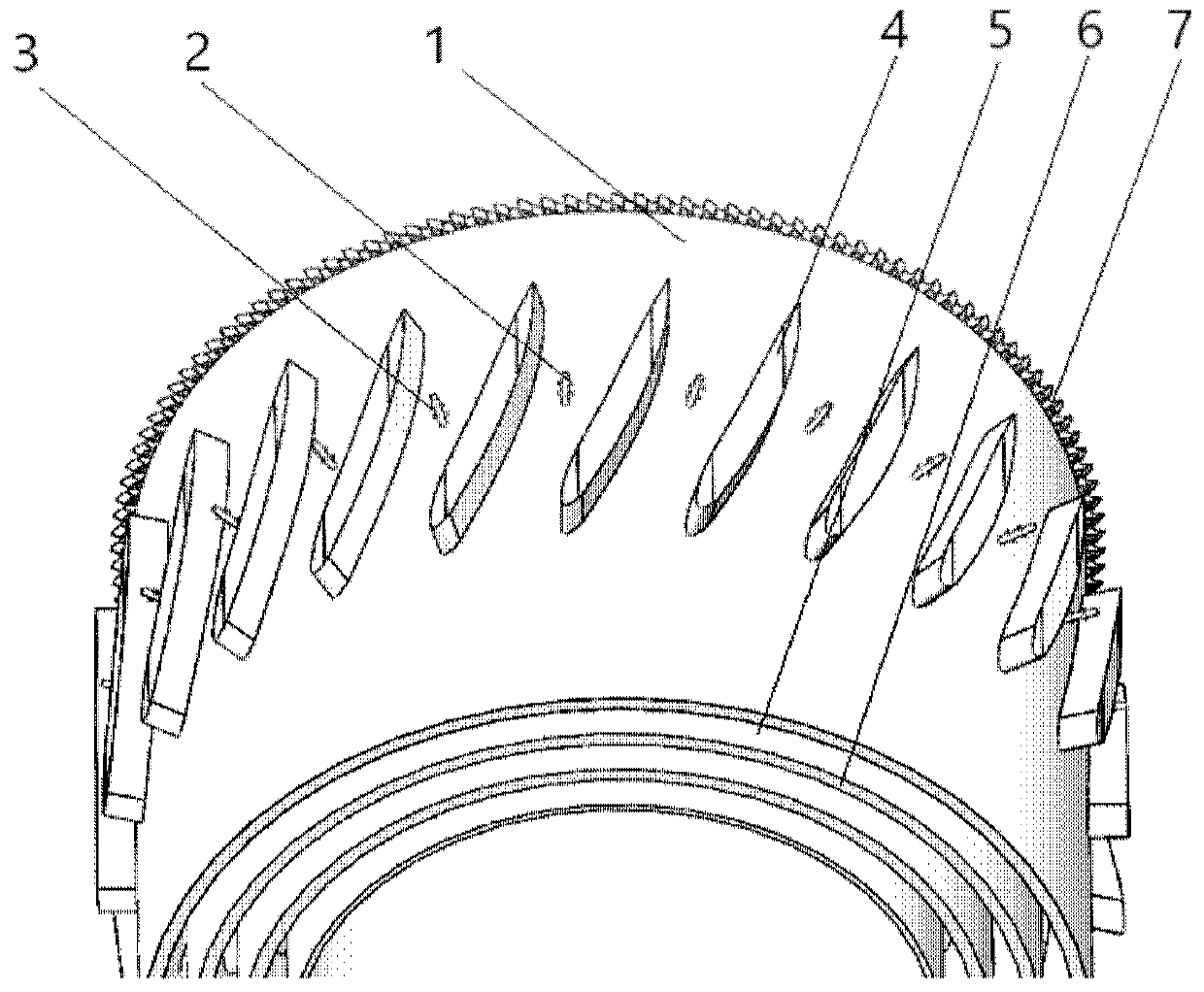

[0017] The invention discloses a two-dimensional array low-pollution combustion device without a traditional swirler, which comprises an annular combustion chamber head, the annular combustion chamber head is divided into a plurality of annular air flow channels, and the outlet of the annular air flow channel is provided with a flame stabilizing structure; a plurality of guide vanes are circumferentially distributed in each annular air flow channel; fuel pipes are arranged between the guide vanes.

[0018] In some embodiments of the present invention, the airflow in the annular airflow channel flows independently;

[0019] In some embodiments of the present invention, the guide vanes in adjacent annular air flow passages ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com