Adjustable range hood and adjusting method thereof

A range hood and adjustable technology, which is applied in the fields of removing oil fume, heating mode, and household heating, can solve the problems of inconvenient cleaning, increased cleaning difficulty, and laboriousness, and achieve the effect of convenient treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

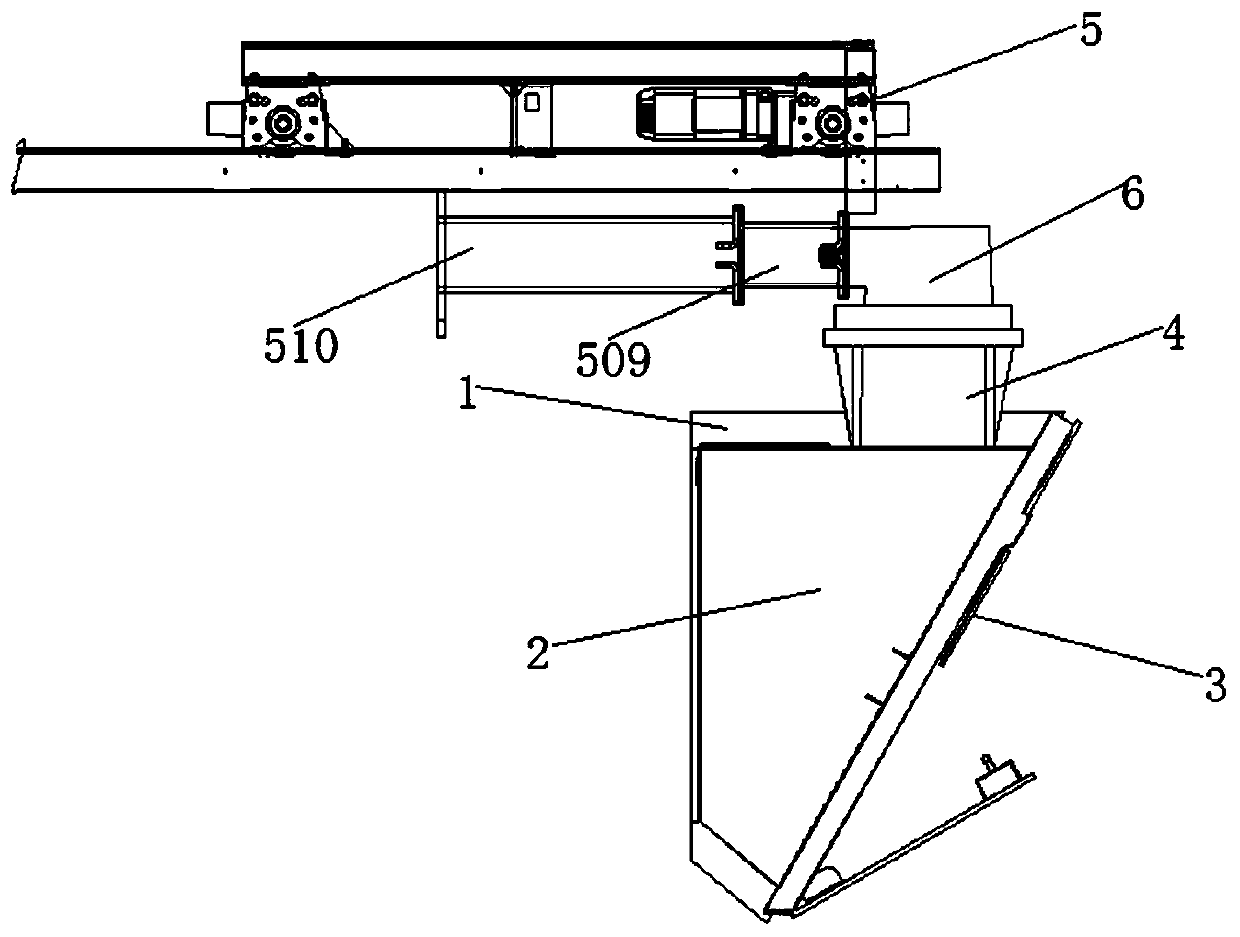

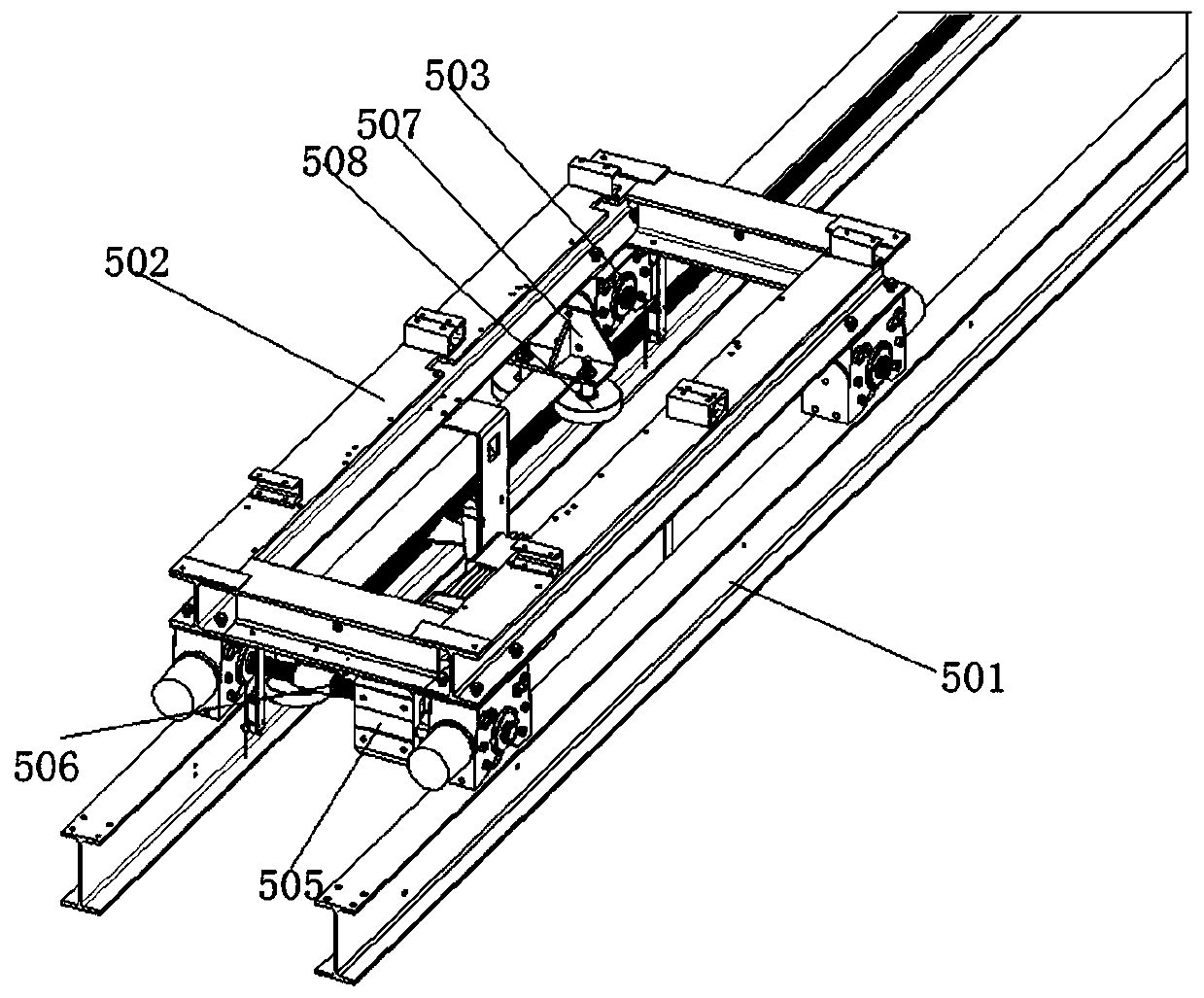

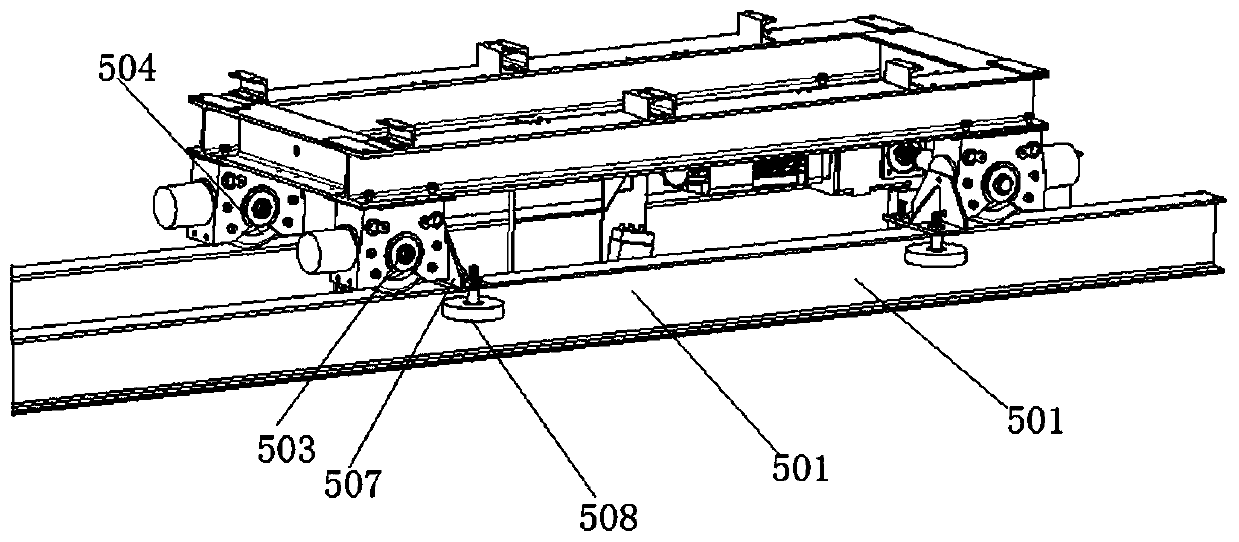

[0054] First, if figure 1 As shown, the adjustable range hood includes: a housing 1 , an exhaust box 2 , a smoke collecting hood 3 , a smoke exhaust pipe 4 and a moving mechanism 5 . The fume collecting hood 3 is fixed obliquely at the front and lower side of the can, and the exhaust box 2 is fixedly installed inside the housing 1 and corresponds to the fume collecting hood 3 for collecting oil fumes. The smoke exhaust pipe 4 is fixed above the housing 1 and communicates with the exhaust box 2 for discharging the collected oil fumes from the smoke exhaust pipe 4 . In order to regulate the distance between the casing 1 and the user, a moving mechanism 5 is fixedly arranged on the wall, and the moving mechanism 5 is connected to the top of the casing 1 by transmission. The moving mechanism 5 Used to control the distance between the housing 1 and the user; when the range hood is in use, the housing 1 is located at the end of the moving mechanism 5, that is, the rear wall of the ...

Embodiment 2

[0074] Based on the above-mentioned embodiment 1, the range hood is pushed to the front of the stove for cleaning. However, in the existing cleaning process, the internal exhaust box 2 is often wiped by taking off the fume collecting hood 3, and this cleaning method needs very frequent processing at first, and if the interval is longer, it will lead to the accumulation of oil fumes. The oil accumulated in the fume collecting hood 3 inside, plus the accumulation of time and the effect of gravity, the oil will drip out, causing the growth of bacteria on the stove. Therefore, the above cleaning is not thorough enough.

[0075] Utilizing the idea of bringing the range hood close to the user proposed in Embodiment 1, a corresponding exhaust box 2 is designed that can collect and treat oil stains well.

[0076] Specifically, such as Figure 5 to Figure 6 As shown, the exhaust box 2 is provided with a smoking mechanism, and the smoking mechanism includes: a housing 101, the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com