Multi-path power supply and clamping positioning coupling device for miniature BOX type laser

A multi-channel power supply, clamping and positioning technology, applied in lasers, laser parts, laser parts and other directions, can solve the problems of disordered tube legs, reduced production efficiency, difficulty in power supply, etc., to reduce production costs and reduce raw material waste. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

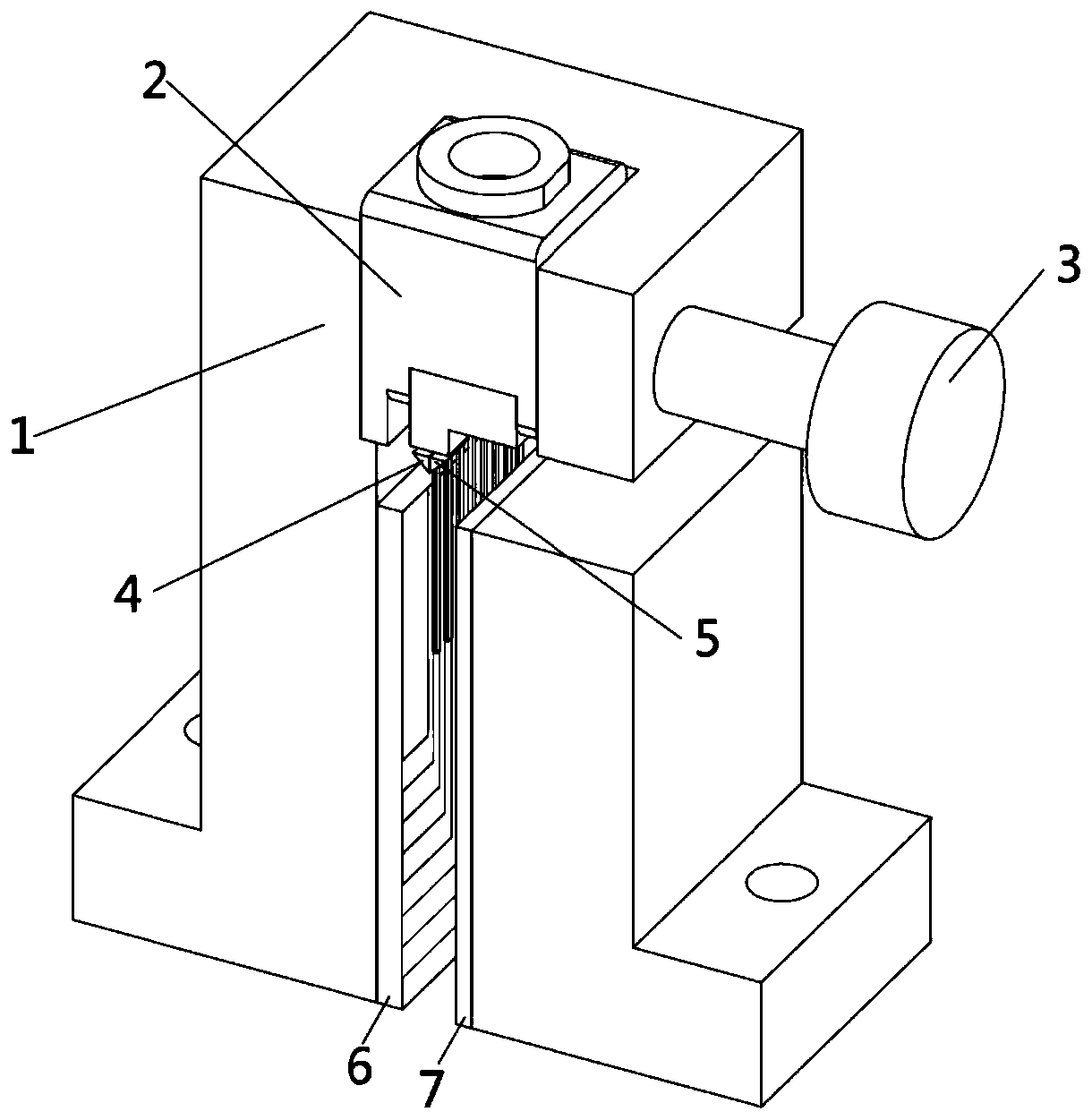

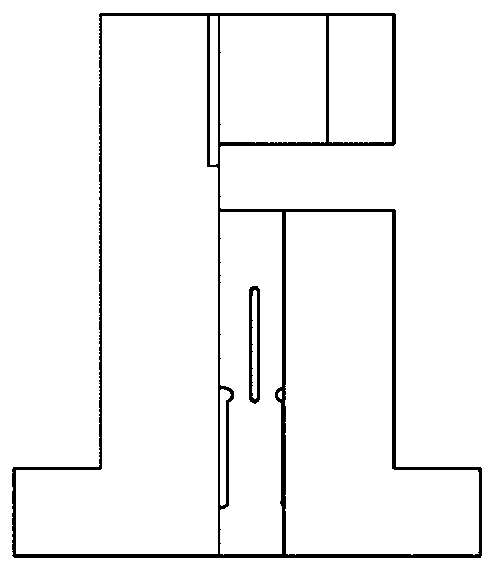

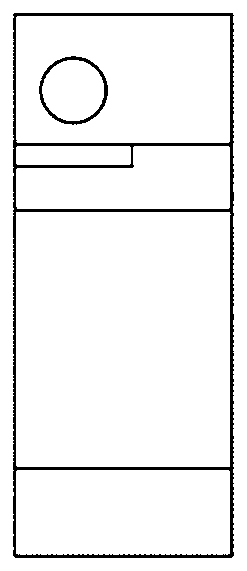

[0027] Such as figure 1 As shown, the present invention is a multi-channel power supply and clamping positioning coupling device for a micro BOX type laser, including a device main body 1, a component to be coupled 2, a top tightening screw 3, a No. 1 smoothing part 4, a No. 2 smoothing part Along the component 5, the No. 1 electrified board 6, the No. 2 electrified board 7. The main body 1 of the device is an integral structure, which is processed by precision numerical control technology, and the parts that may interfere are evacuated to ensure that the actual size meets the design requirements; the main body 1 of the device is in a convex shape as a whole, and each A through hole is set, and the horizontal displacement platform on the coupling machine is connected through two through holes; a vertical t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com