pneumatic tire

一种充气轮胎、轮胎的技术,应用在特殊轮胎、轮胎零部件、胎沿等方向,能够解决刚性变低等问题,达到提高刚性、减轻轮胎重量、维持行驶性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

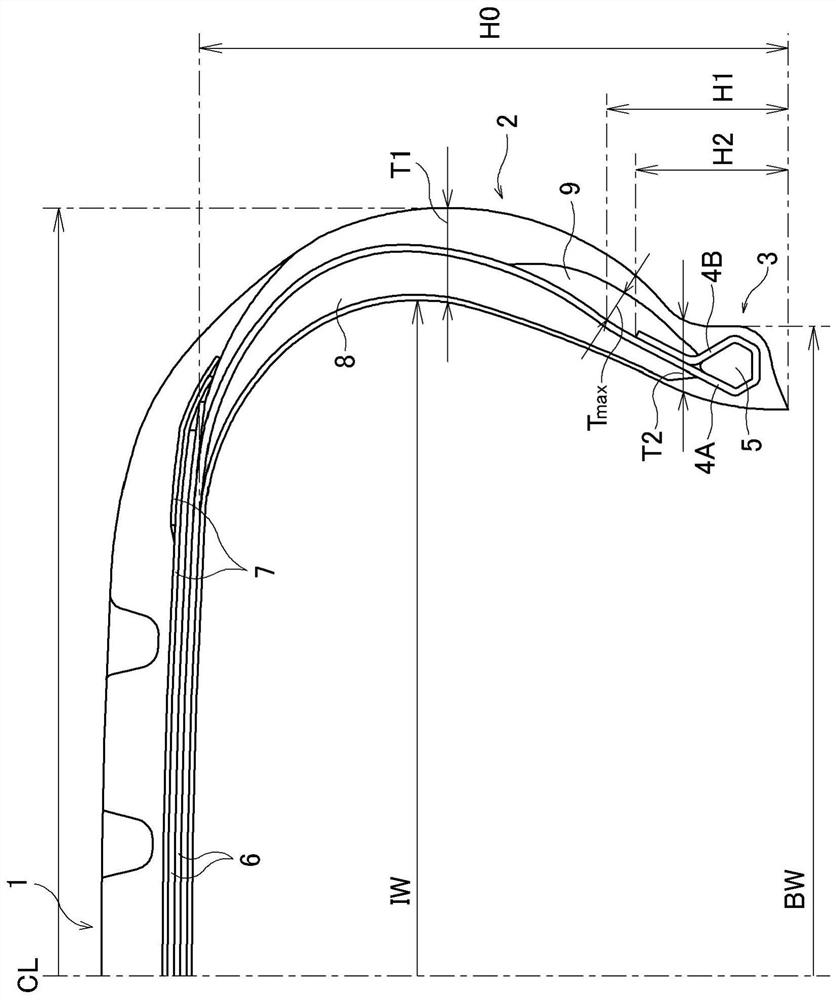

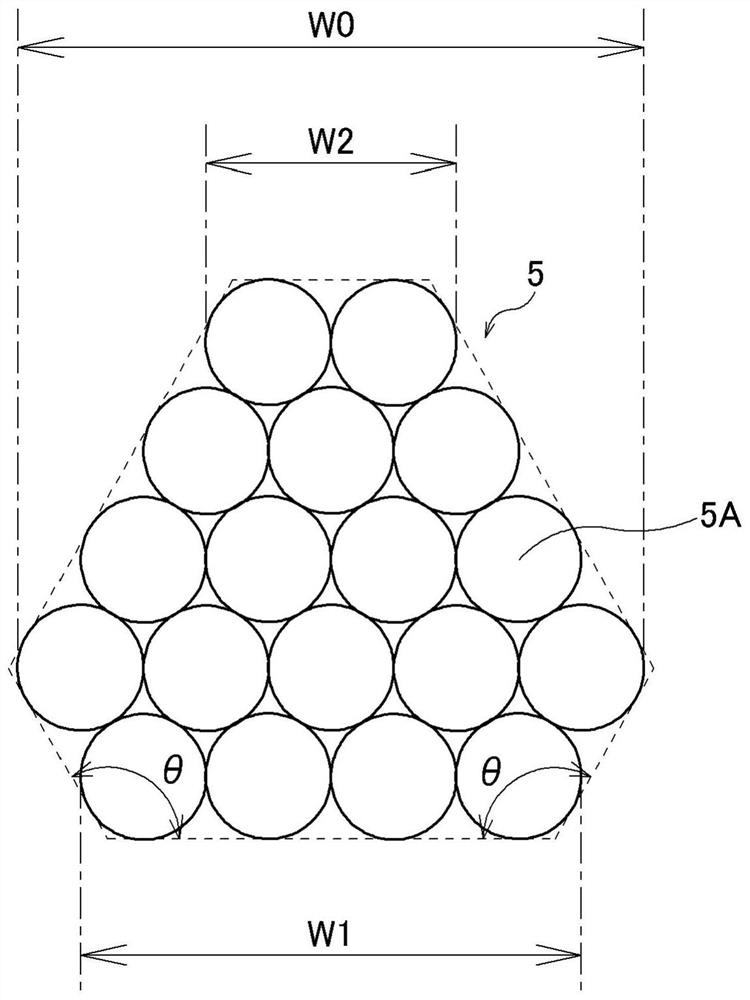

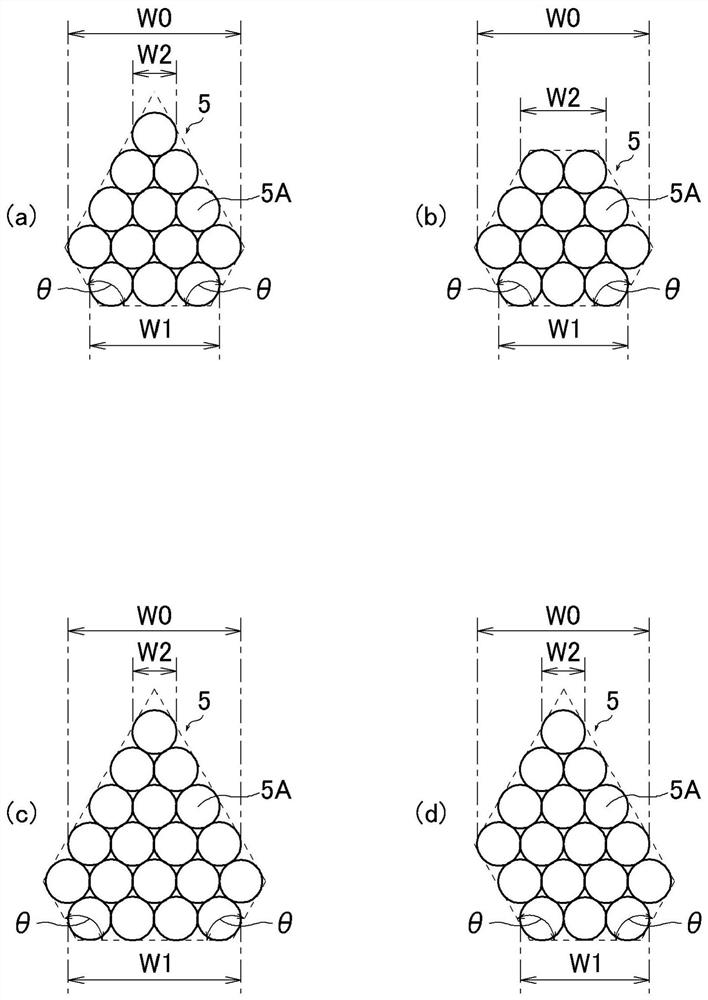

[0052] The tire size is 205 / 55R16 with figure 1 In the basic structure shown, the presence or absence of bead filler arranged between the main body portion of the carcass layer and the turnback portion, and the presence or absence of a filler layer arranged outside the main body portion of the carcass layer and the turnback portion in the tire width direction , the structure of the bead core, the maximum width W0 of the bead core, the width W1 of the innermost layer of the bead core in the tire radial direction, the width W of the outermost layer of the bead core in the tire radial direction, and the difference between the widths W1 and W2 Size relationship, ratio W2 / W0, rubber occupancy in the closed area, cross-sectional area S1 and hardness H1 of the side reinforcement layer, cross-sectional area S2 and hardness H2 of the packing layer, (S2×H2) / (S1×H1), The position of the end of the folded portion of the carcass ply, the ratio IW / BW of the rim width BW to the maximum width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com