Sock body of novel sock shoe and sock body manufacturing process of sock shoe

A sock and sock body technology, applied in the field of socks and shoes, can solve the problems of no massage function and achieve good massage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

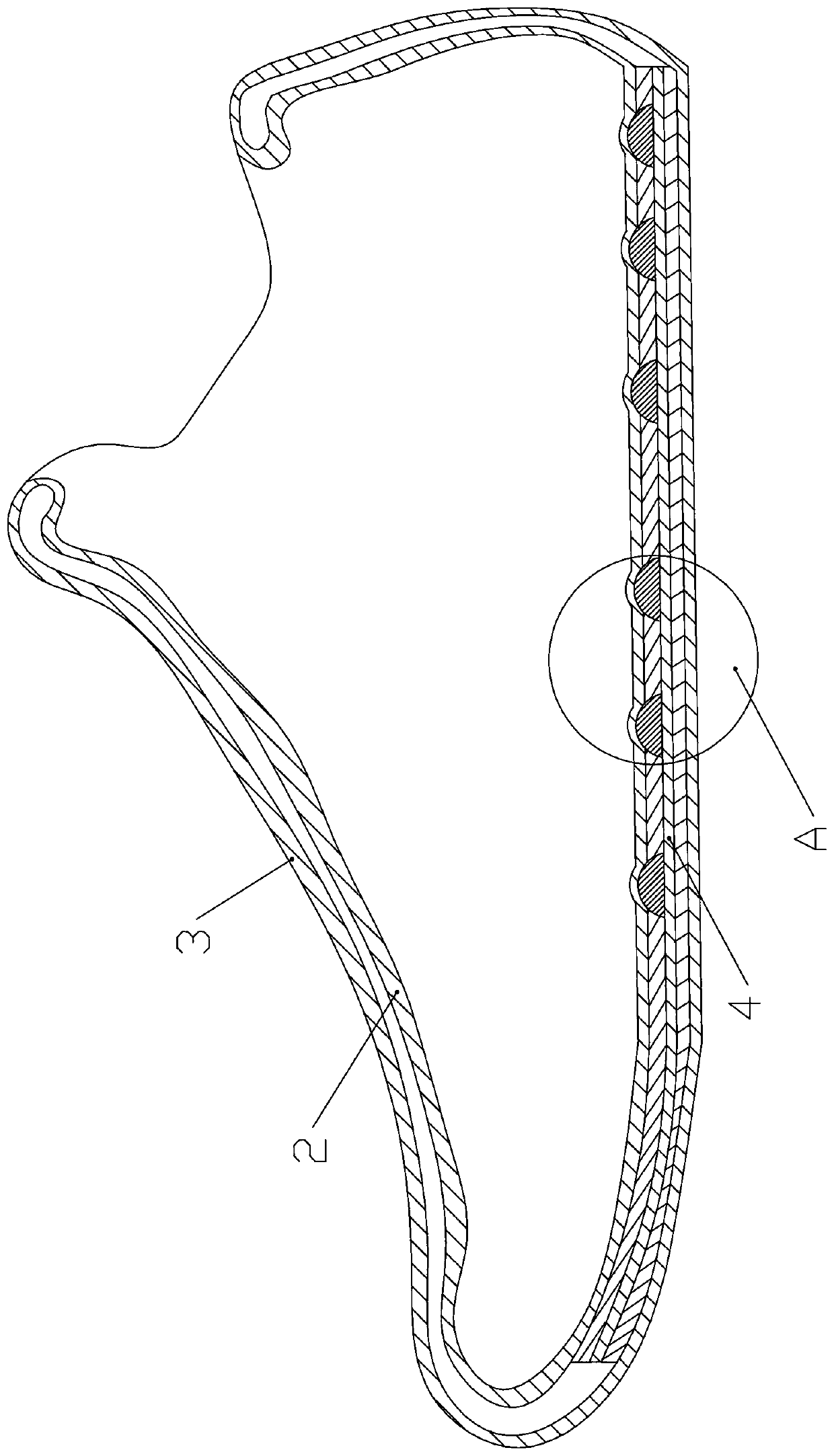

[0033] combine figure 1 and figure 2 , it can be known that a sock body of a new type of sock shoe includes a main body 1, wherein the main body 1 includes an inner layer 2 and an outer layer 3, wherein the inner layer 2 and the outer layer 3 can be stitched or integrally formed, that is, formed by a piece of textile cloth. Floor. The former may be easier to operate than the latter, but the latter is more comfortable in terms of appearance and comfort, because there are not too many connection ports, only one connection port and located at the bottom, so it has a better look and feel.

[0034] When the inner layer 2 and the outer layer 3 are integrally formed, the actual manufacturing process of the structure is to first put the textile cloth on the foot mold to form the inner layer 2, and then turn it over from the opening and then put it on the foot in reverse. On the mold, thereby forming two layers, and the second layer is the outer layer 3, and then the sewing of the ...

Embodiment 2

[0044] A kind of manufacturing process of sock body, the steps of making the sock body of embodiment one are as follows:

[0045] 1) Put the tubular textile cloth with an open end on the foot mold first, so that the textile cloth covers the surface of the foot mold evenly, and use this part of the textile cloth covering the surface of the foot mold as the inner layer of the sock body 2 ;

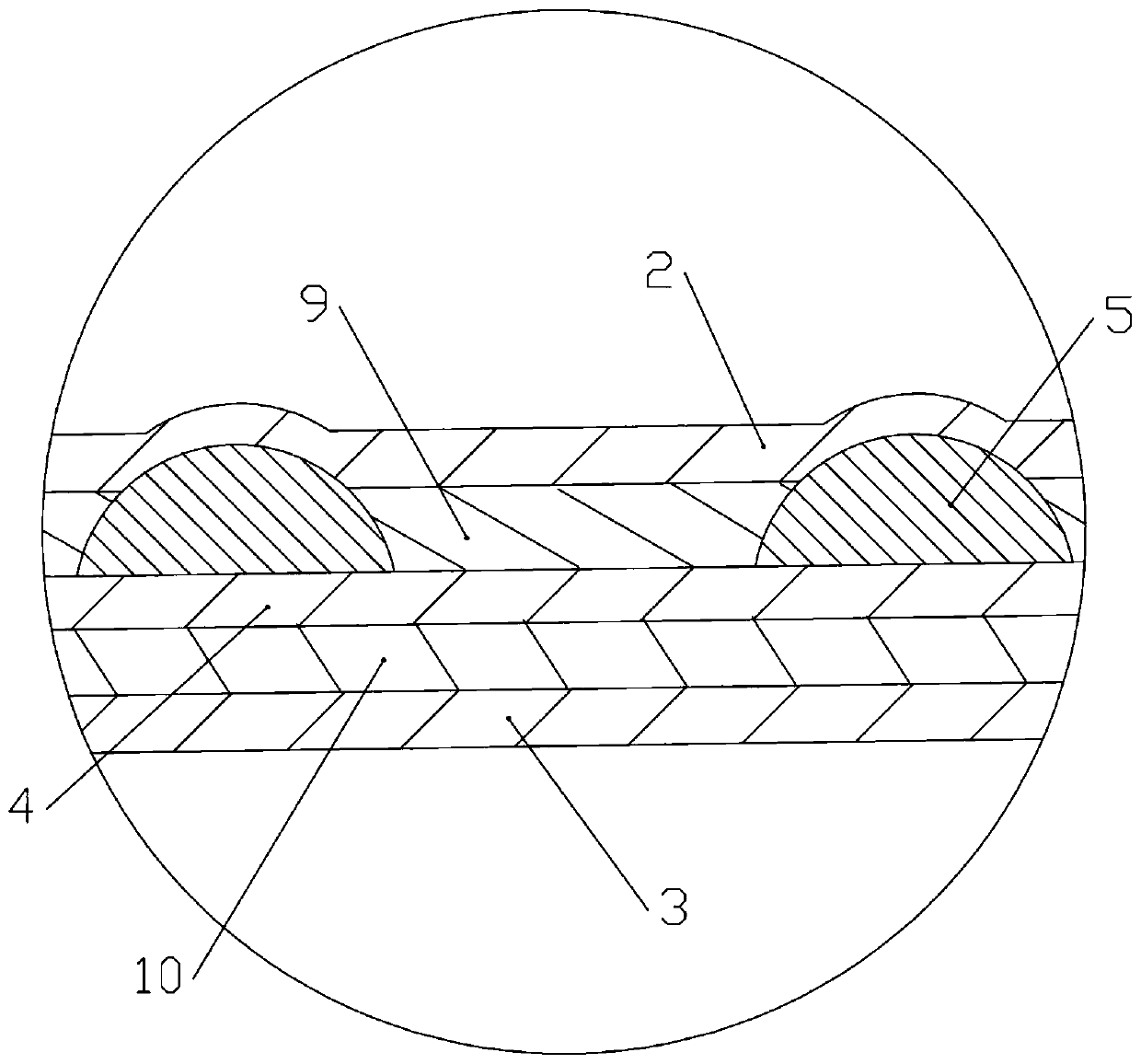

[0046] 2) An inner pad 4 is placed on the outer side of the inner layer 2 at the bottom of the foot mold, and a first thermal fuse layer 9 is placed between the inner pad 4 and the inner layer 2;

[0047] 3) A second thermal fuse layer 10 is placed outside the inner pad 4;

[0048] 4) Fold the textile cloth at the ankle of the foot mold, and put it on the foot mold in reverse, so that the opening of the textile cloth is gathered at the bottom of the foot mold and is located outside the second thermal fuse layer 10, Thereby forming the outer layer 3 of the sock body, and the woven cloth inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com