Planar jewelry shape follow-up measurement processing control method

A control method and jewelry technology, applied in the direction of metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of low scrap rate, engraving pattern error, high product scrap rate, etc., so as to save material cost and improve Effects of machining accuracy and reduction in scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solution in the embodiment of the invention in conjunction with the accompanying drawings in this embodiment,

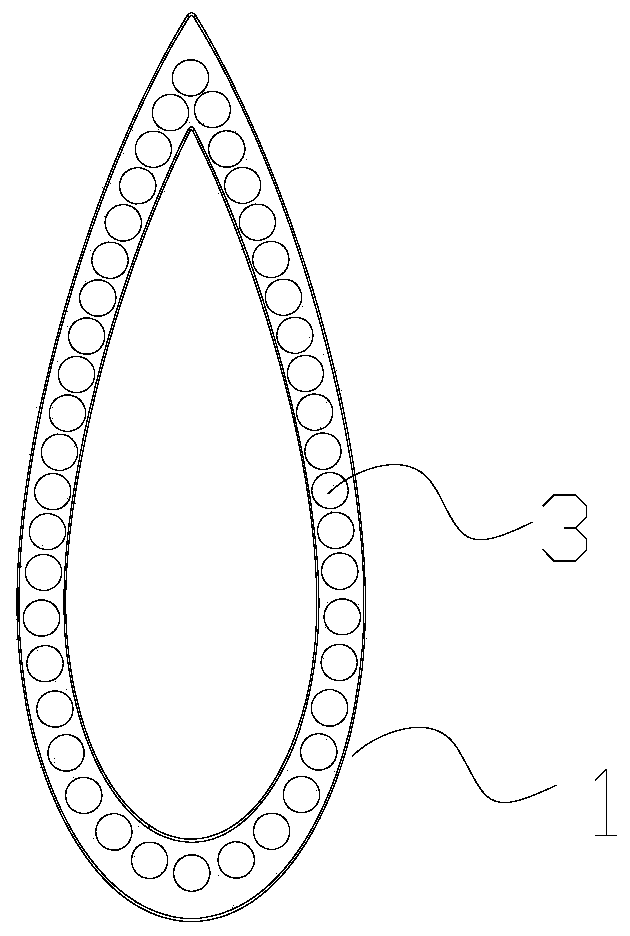

[0029] At present, CNC machine tools are only used to process hard metal materials such as stainless steel and cast iron, and have not been found to be used in large-scale industrialized unified automatic production in the field of jewelry processing. This is because the shape, size, texture, and inner and outer patterns of different jewelry are different, and because each jewelry rough body has a difference in thickness and size at the millimeter level. Therefore, at present, jewelry processing usually relies on manual processing and simple electric polishing tools. The appearance of such jewelry is not bright, and the patterns are not dense and beautiful.

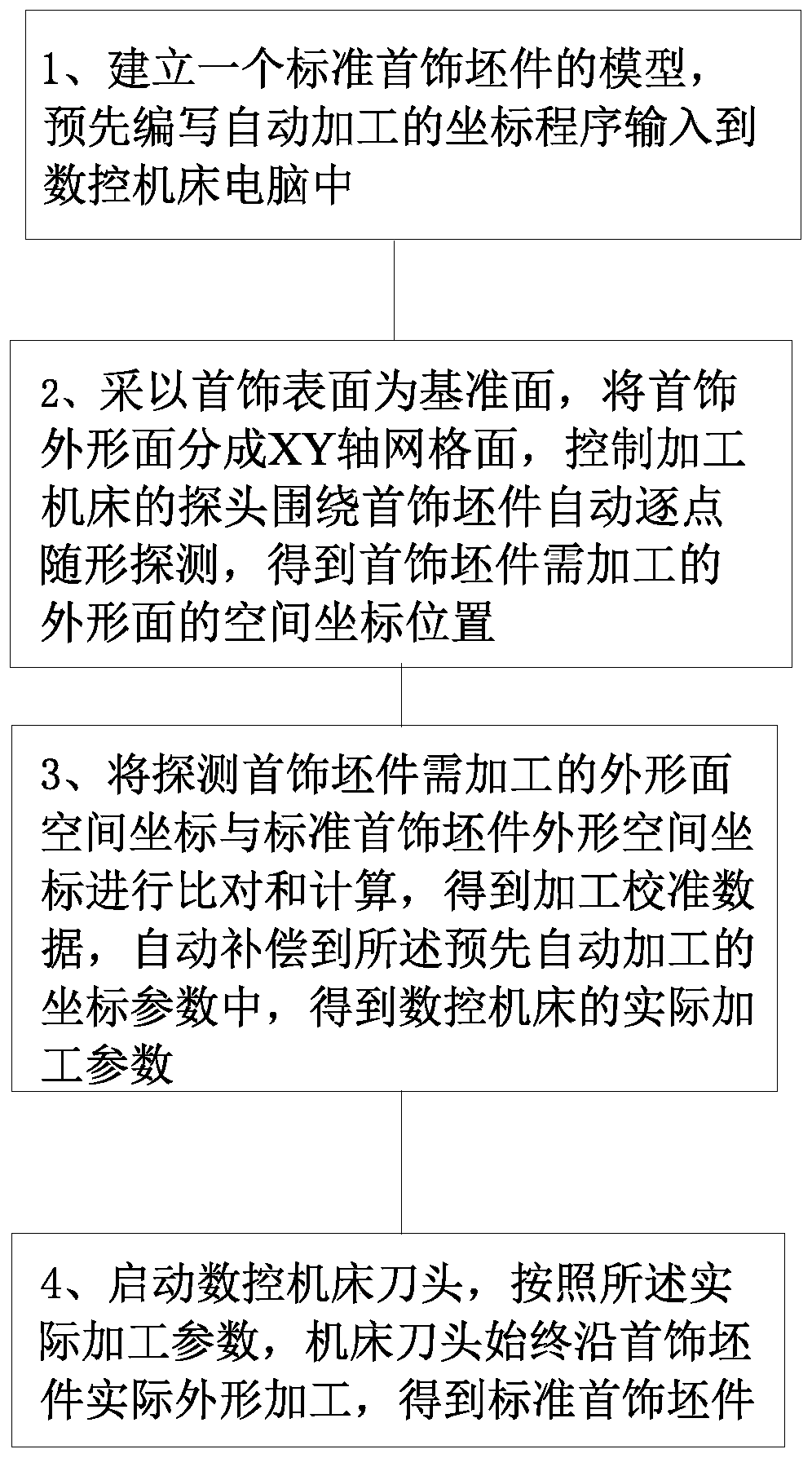

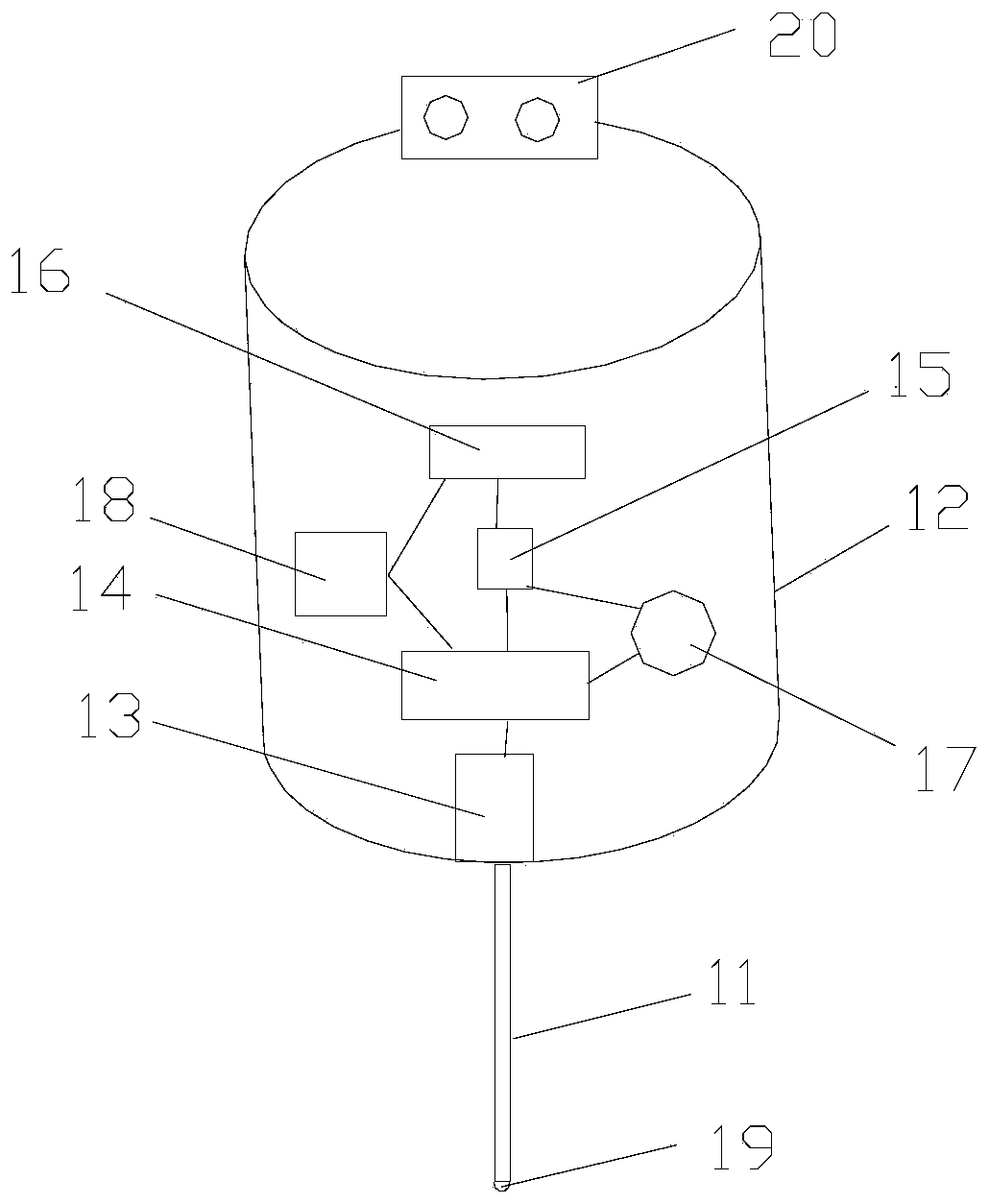

[0030] The invention improves the processing technology. After thousands of development tests, it proposes the application of the conformal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com