Automatic shoelace tying machine

An automatic technology for tying shoelaces, applied in clothing, applications, hangers, etc., can solve problems such as difficult to tie shoelaces, not suitable for home use, complex structure, etc., and achieve the effect of stable function, simple structure and efficient action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

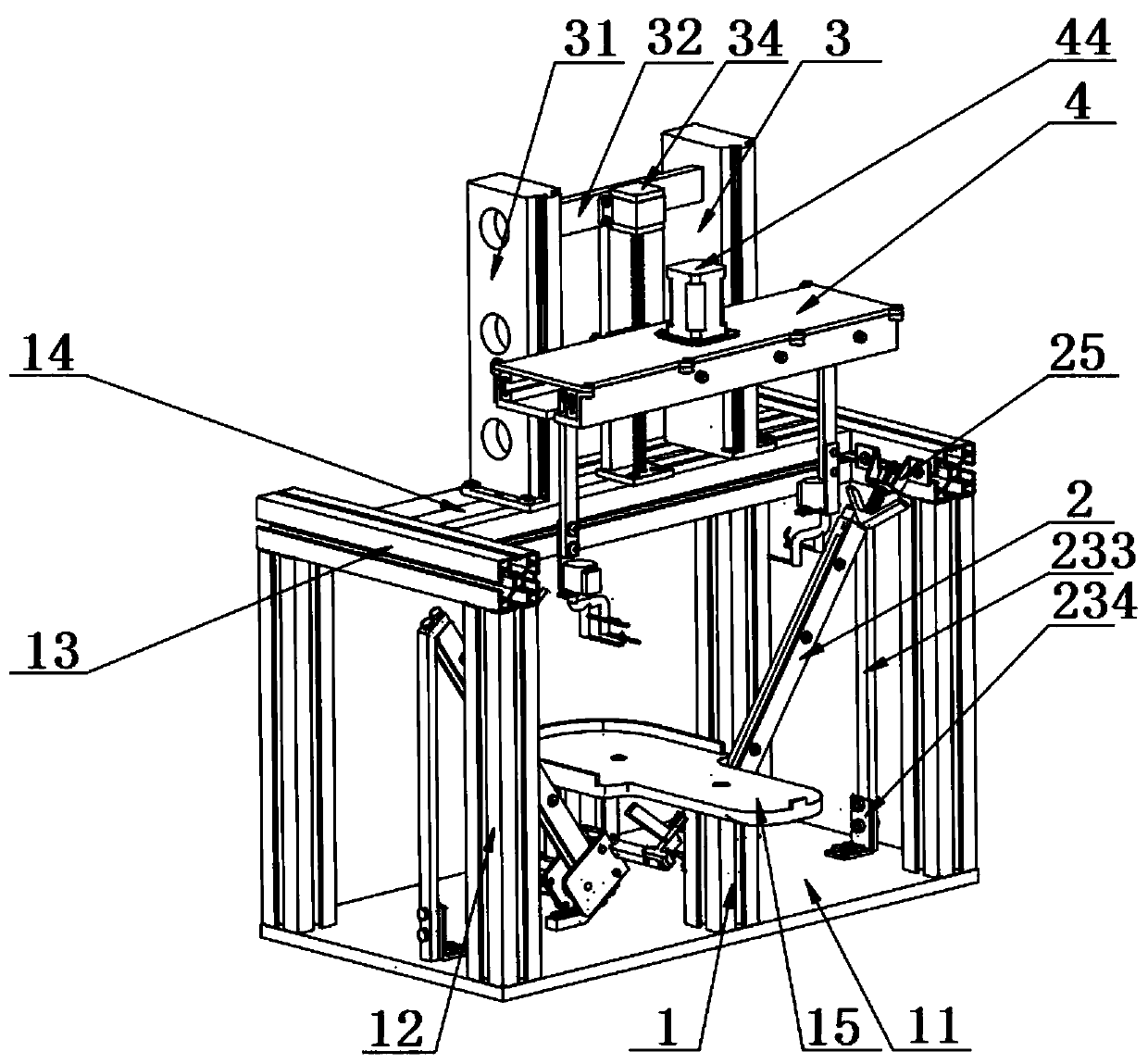

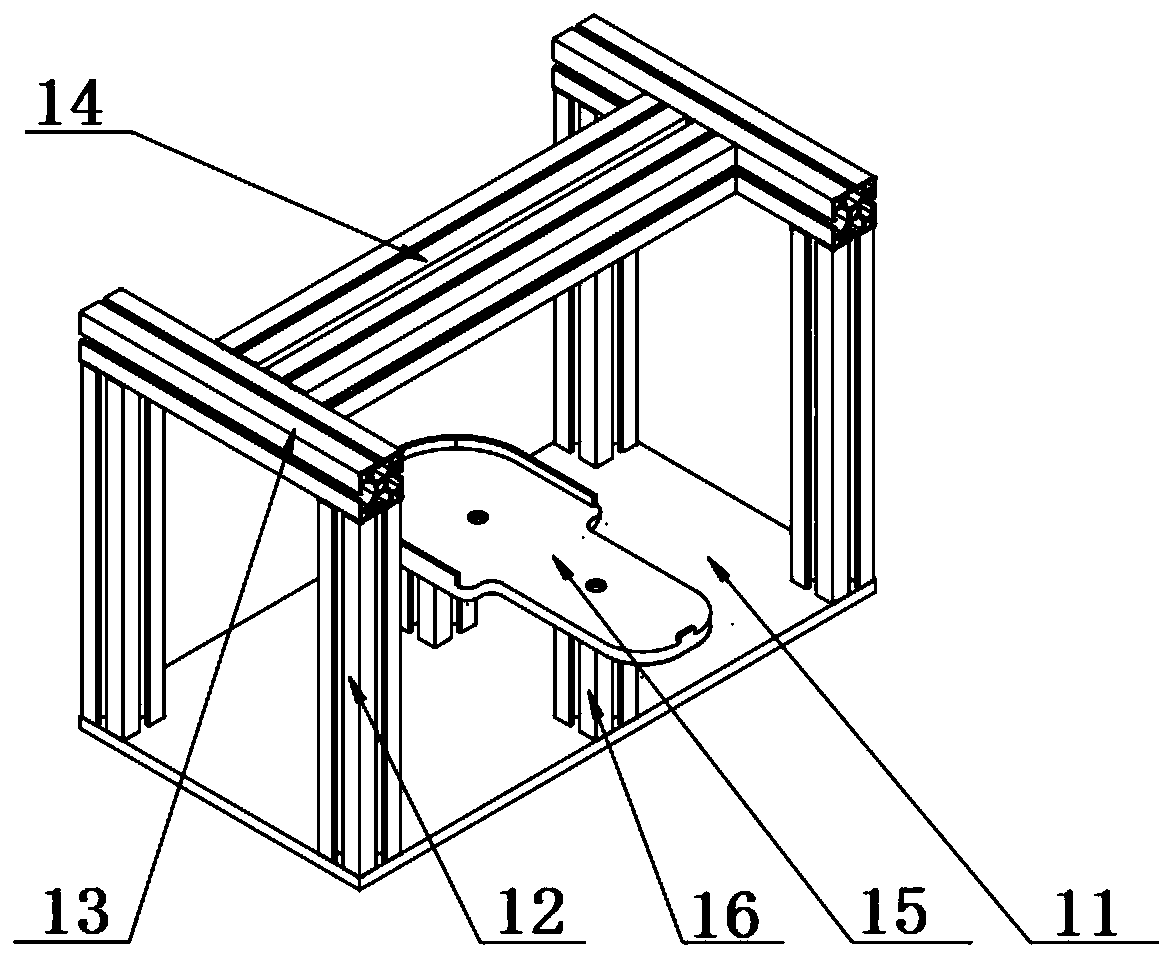

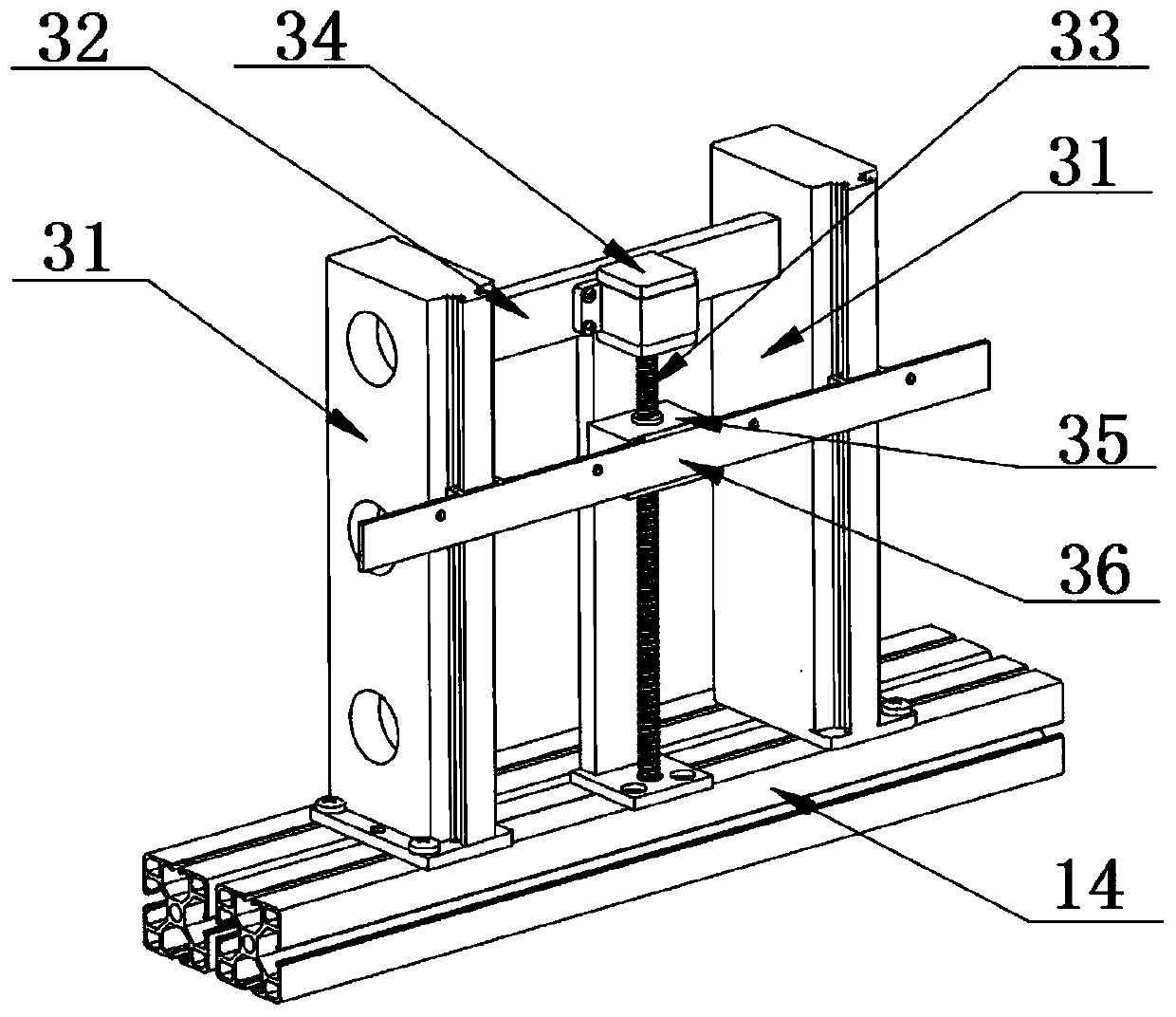

[0054] Embodiment: a kind of automatic shoelace machine, as figure 1 As shown, it includes a frame 1, two sets of shoe strings hooking up a tensioning mechanism 2, a lifting mechanism 3 and a horizontal knotting mechanism 4. Wherein the frame 1 is composed of a base plate 11, four vertical columns 12 arranged perpendicular to the base plate 11, two longitudinal supports 13 arranged horizontally on both sides and connected with the tops of the columns 12, and horizontally arranged between the two longitudinal supports 13. The transverse bracket 14 is formed, and the relative middle part of the base plate 11 is provided with a shoe support plate 15, and the bottom of the shoe support plate 15 is supported on the base plate 11 by a shoe support plate support 16, as figure 2 shown.

[0055] refer to Figure 7-9 Two sets of shoe rope hooking and tensioning mechanisms 2 are respectively arranged on both sides of the shoe support plate 15, respectively corresponding to the two sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com