Method for polishing connecting rod arc face

An arc surface and connecting rod technology, applied in grinding/polishing equipment, grinding machines, manufacturing tools, etc., can solve the problems of difficult to guarantee polishing accuracy, bulky products, time-consuming and labor-intensive, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with drawings and embodiments.

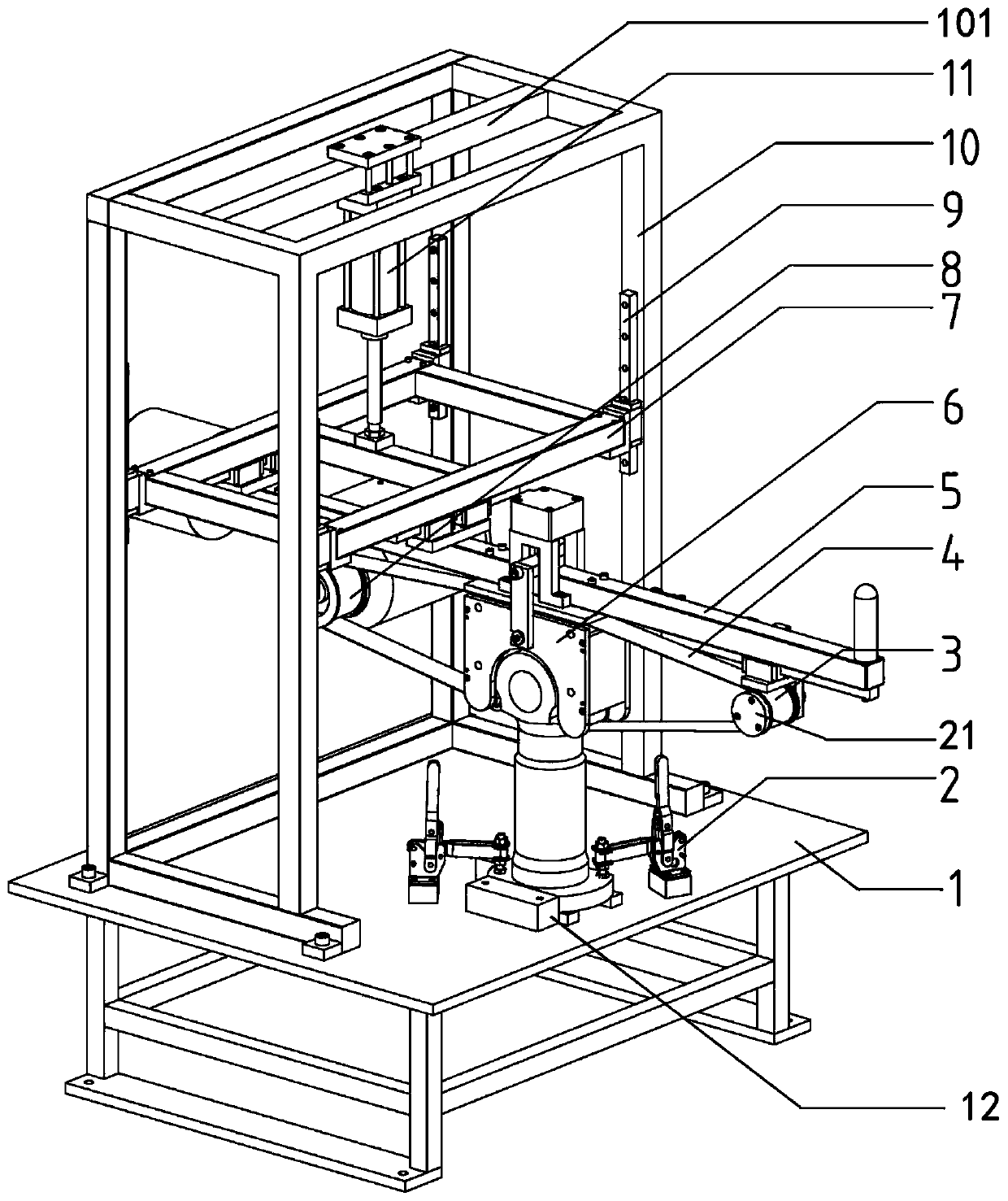

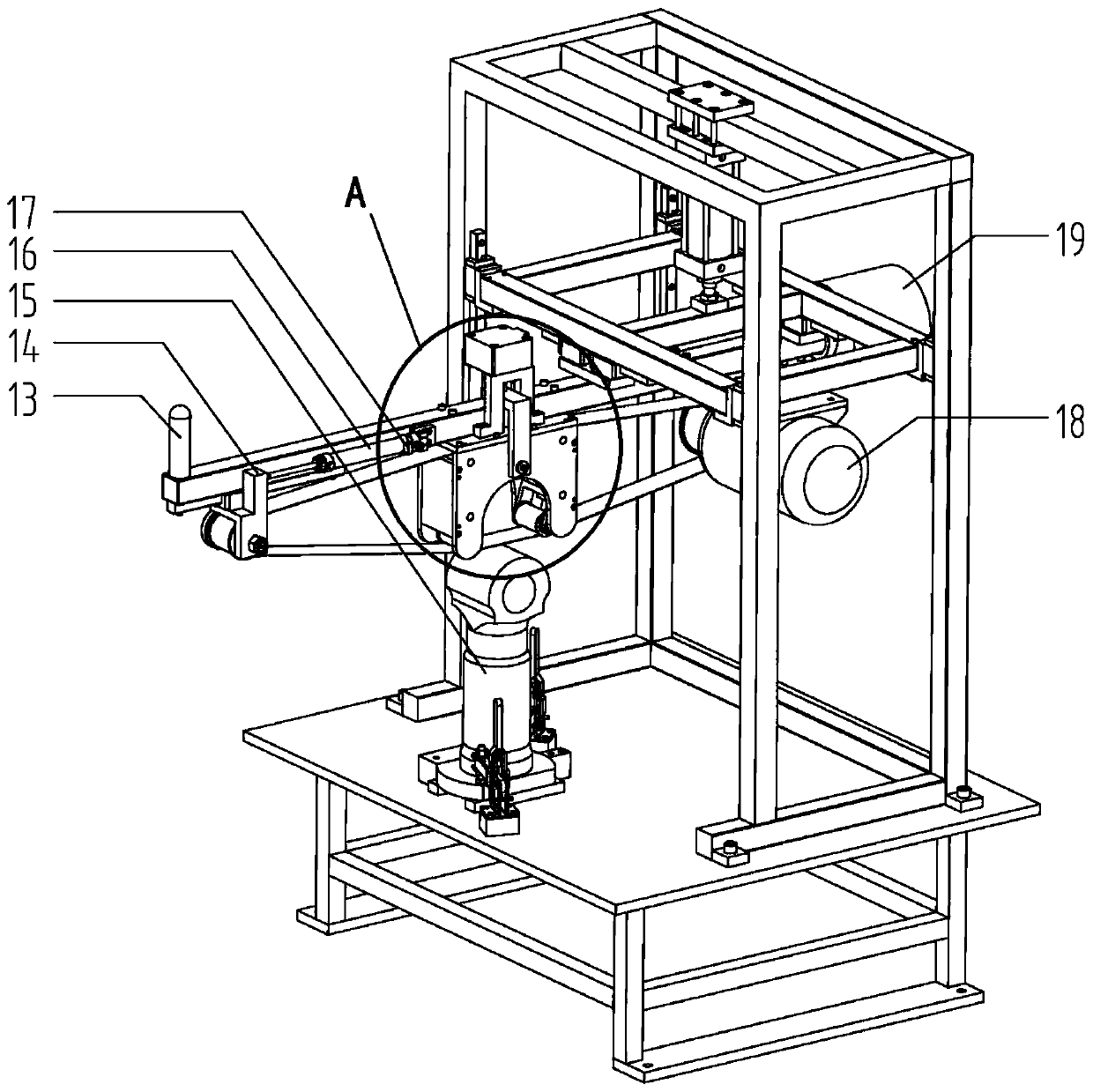

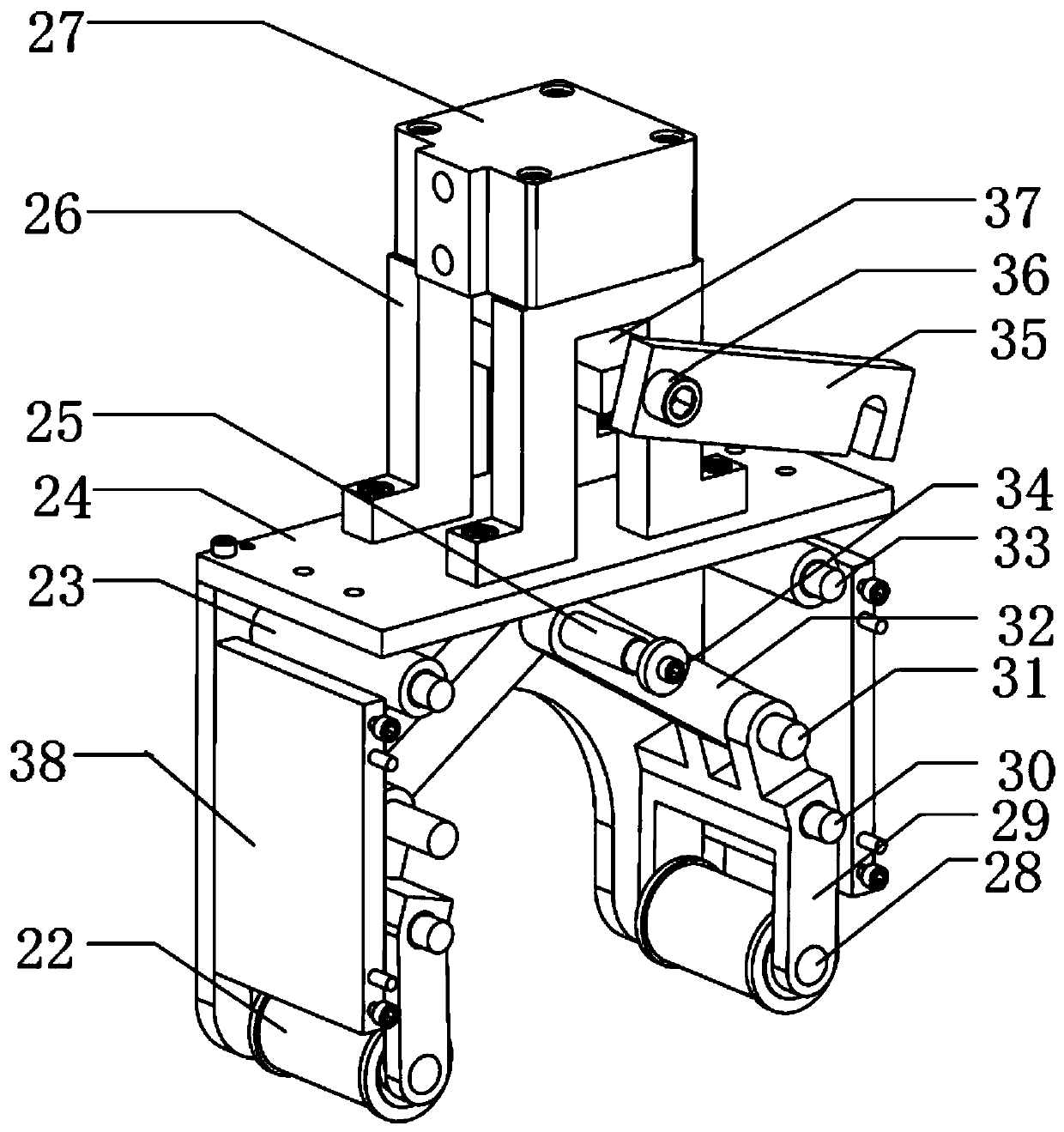

[0025] Such as Figure 1~6 As shown, the device for polishing the circular arc surface of the connecting rod using the method of the present invention includes a lifting unit, a polishing belt operating unit, a hinge loosening unit, a workpiece fixing unit, and a left and right moving unit. The workpiece in the present embodiment is the connecting rod 15, and the arc surface to be polished is the arc surface of the connecting rod, and the included angle of the arc surface is 200°, as Figure 7 20 in.

[0026] It specifically includes the base 1 and the load-bearing frame 10 arranged above the base. A cross bar 101 is installed in the middle of the top surface of the load-bearing frame 10. The lifting cylinder 11 of the lifting unit is fixed under the cross bar 101. The air source of the lifting cylinder 11 is two-way The reversing air source is controlled by the three...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com