Polishing method for radiation rib of die-casting mould

A technology of cooling ribs and die-casting molds, used in grinding/polishing equipment, machine tools with surface polishing, manufacturing tools, etc., can solve the problems of difficult polishing of mold cooling ribs, improve mold life, solve polishing difficulties, and improve product quality. The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

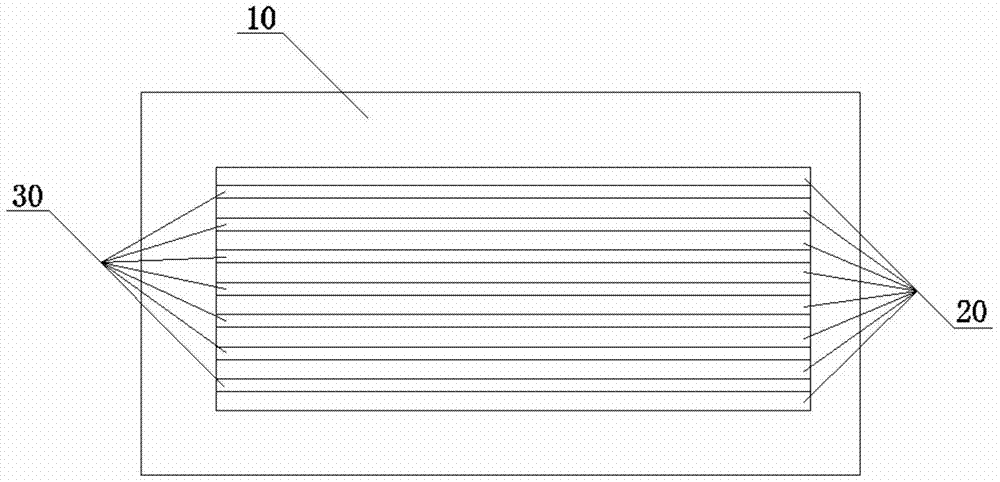

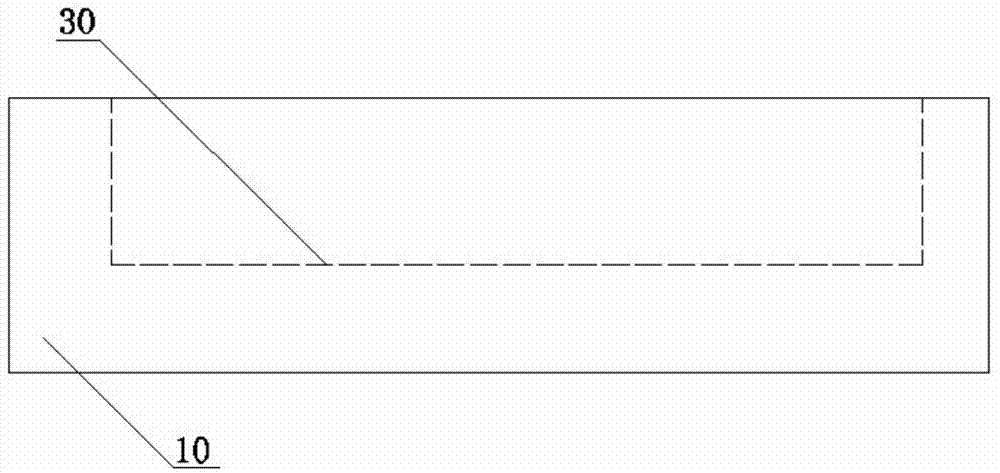

[0023] see Figure 1~2 , Figure 1~2 It is a schematic diagram of the structure of heat dissipation ribs of a die-casting mold, wherein, 10 is a mold, 20 is a mold rib, there are several mold ribs 20, and there are small gaps 30 between two mold ribs 20, and these small gaps 30 are often Difficult to polish in place.

[0024] The polishing method for the heat dissipation ribs of the above-mentioned die-casting mold includes the following steps:

[0025] (1) Coarse throwing:

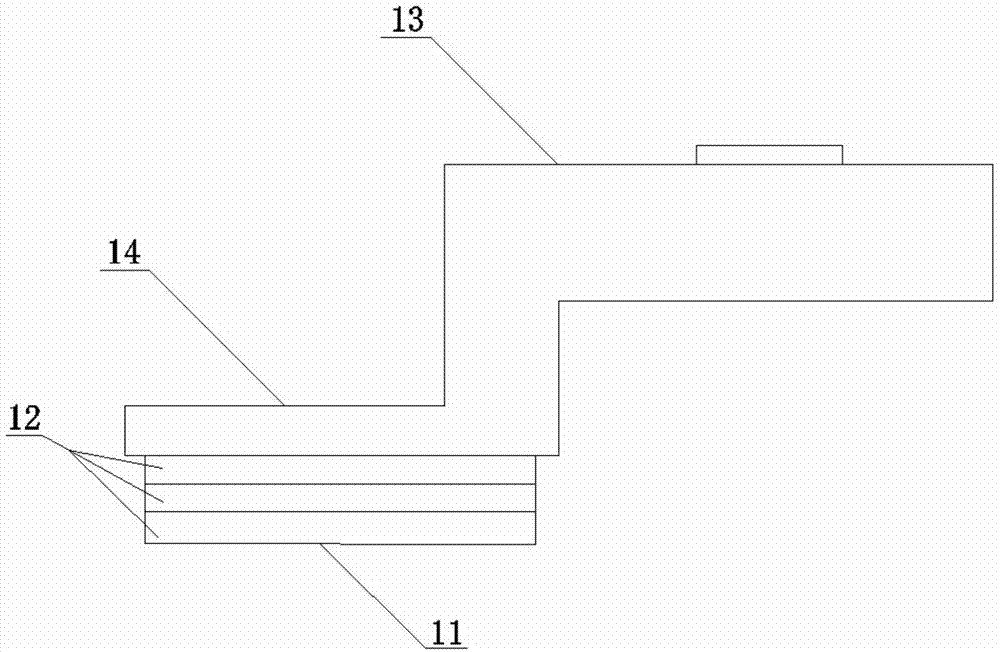

[0026] Use the sandpaper disc 11 to polish the two sides of the small gap 30. The two sides are flat and have a large area, and the sandpaper disc 11 is used to polish the efficiency; the roughness of the sandpaper disc 11 is #150, and it is composed of three layers of sandpaper bonded in sequence , the sandpaper disc 11 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com