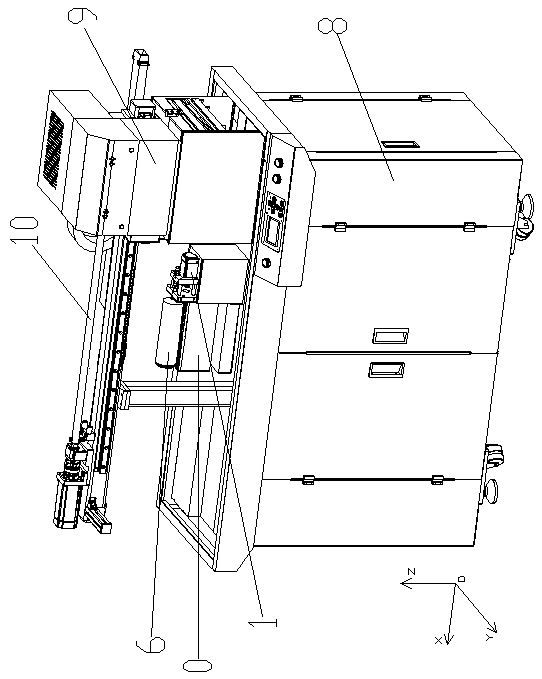

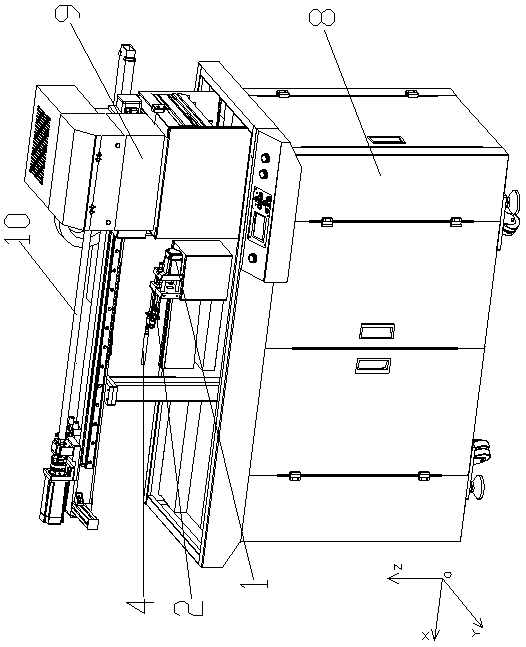

To-be-printed object mounting mechanism for ink-jet printer and mounting method

A technology of installation mechanism and installation method, which is applied to printing devices, typewriters, printing, etc., can solve the problems of affecting inkjet quality, installation, and failure to pass fixtures, etc., so as to facilitate software control of ink and ensure the quality of inkjet printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

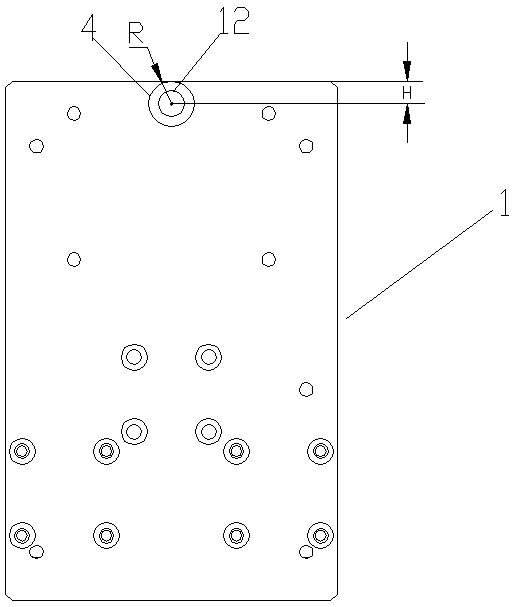

[0042] When it is necessary to print a small-diameter cylindrical object 4 to be printed, such as Figure 6 As shown, an object to be printed transfer mechanism 2 is connected to the outer end of the drive output shaft 12 of the object to be printed driving mechanism 1 , and an object to be printed 4 is connected to the output end of the object to be printed transfer mechanism 2 . The following is based on Figure 7-8 Describe in detail the transfer mechanism 2 of the object to be printed in this embodiment. The transfer mechanism 2 of the object to be printed includes a coupling 21, a connecting column 22, a first friction wheel 23, a first output shaft 24, a floating friction wheel 25, a floating shaft 26. The second friction wheel 27, the second output shaft 28 and the rear support seat 29. One end of the coupling 21 is connected to the drive output shaft 12 of the drive mechanism 1 of the object to be printed, and the other end is connected to the first drive of the transf...

Embodiment 2

[0046] When it is necessary to print a small-diameter object 4 to be printed, it can also be Figure 9 As shown, another object to be printed transfer mechanism 3 is connected to the outer end of the drive output shaft 12 of the object to be printed driving mechanism 1 , and the object to be printed 4 is connected to the output end of the object to be printed transfer mechanism 3 . The following is based on Figure 10-11 Describe in detail another transfer mechanism 3 for objects to be printed. The transfer mechanism 3 for objects to be printed includes a shaft coupling 21, a connecting column 22, an output shaft A31, a first gear 32, an output shaft B33 and a second gear 34. The shaft coupling One end of the device 21 is connected to the drive output shaft 12 of the drive mechanism 1 of the object to be printed, and the other end is connected to the output shaft A31 of the transfer mechanism 3 of the object to be printed. A first gear 32 is inserted on the output shaft A31, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com