Auxiliary replacement tool for cable bridge

A cable tray and tool technology, which is applied in the field of auxiliary replacement tools for cable trays, can solve the problems of complex structure, high cost, and difficulty in lifting cables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

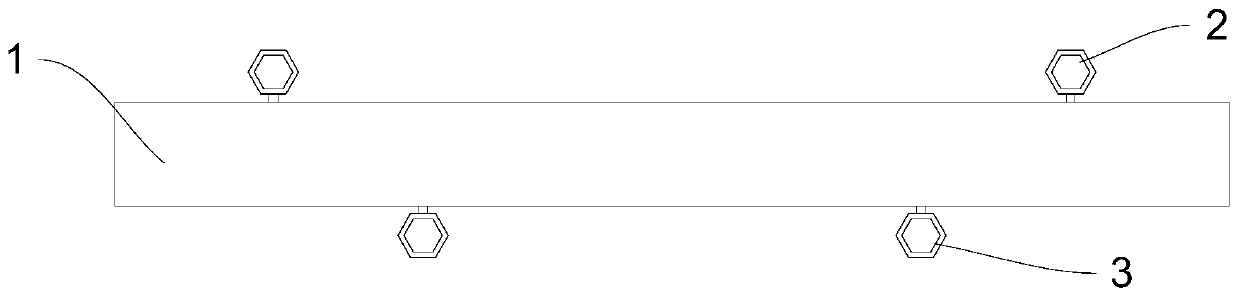

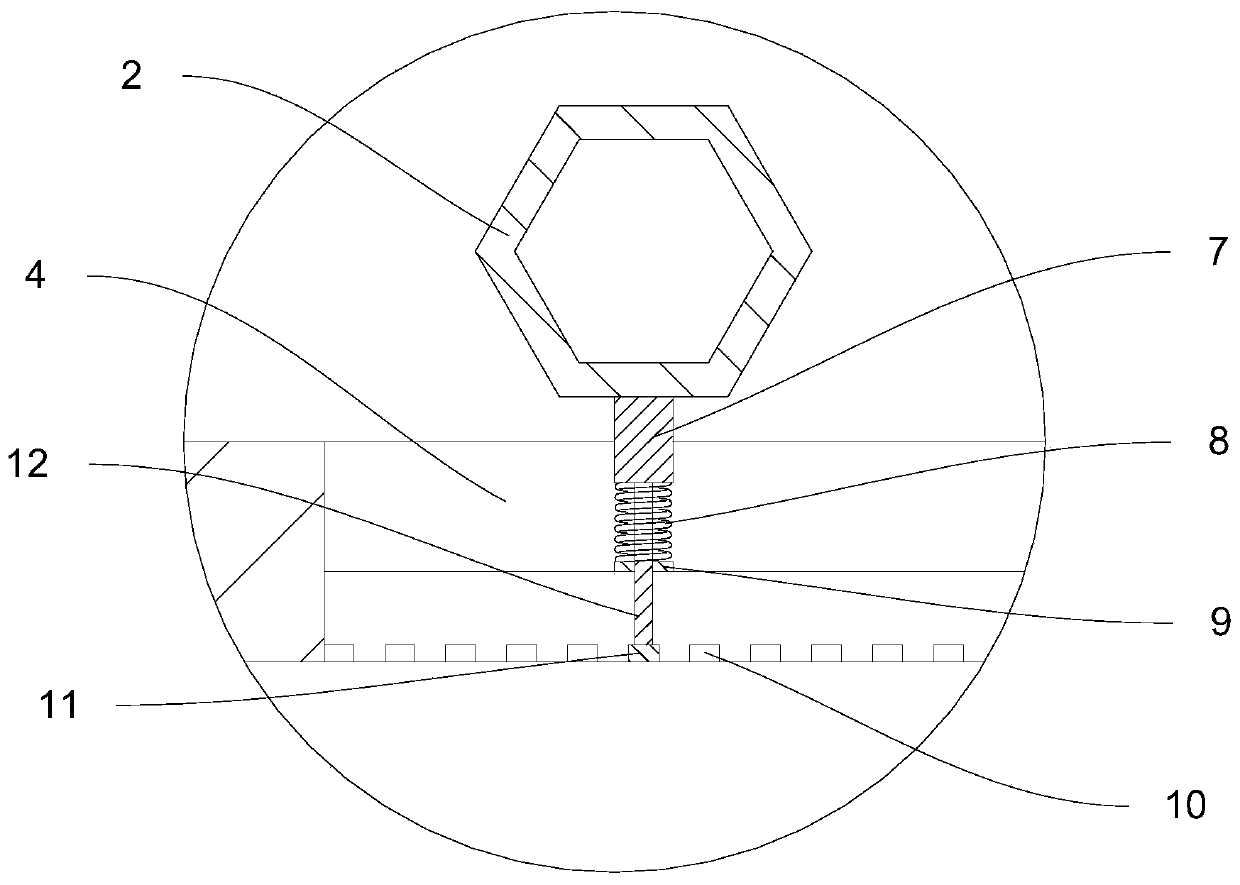

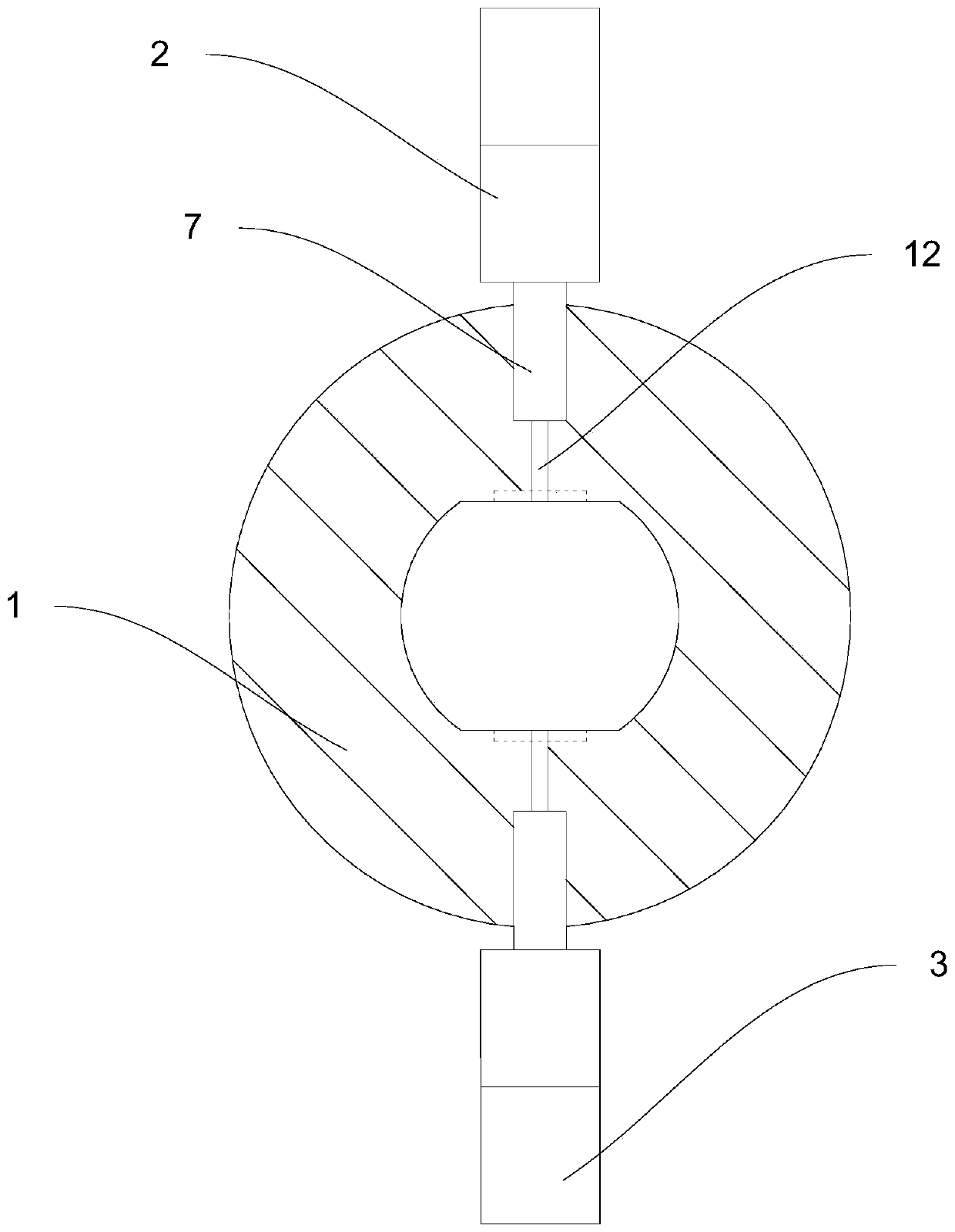

[0034] Please refer to Figure 1-Figure 5 , this embodiment provides an auxiliary replacement tool for cable bridges, which solves the problem that when the existing hangers are installed on the wall, on the one hand, the wall will be damaged; The problem of the hanging weight of the rack.

[0035] An auxiliary replacement tool for a cable bridge, comprising a main body rod 1, the above-mentioned main body rod 1 is placed horizontally, the upper side of the above-mentioned main body rod 1 is symmetrically provided with a first connecting seat 2 with respect to the longitudinal tangent line in the middle, and the lower side of the above-mentioned main body rod 1 is about The middle longitudinal tangent is symmetrically provided with a second connecting seat 3 .

[0036]The use method of the present invention: before the cable tray needs to be replaced, the cables on the cable tray need to be hoisted, and the main body pole 1 is placed horizontally so that the two first connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com