Steel ladle bottom argon blowing smelting method

A smelting method and a bottom blowing argon technology, applied in the field of steelmaking refining process production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

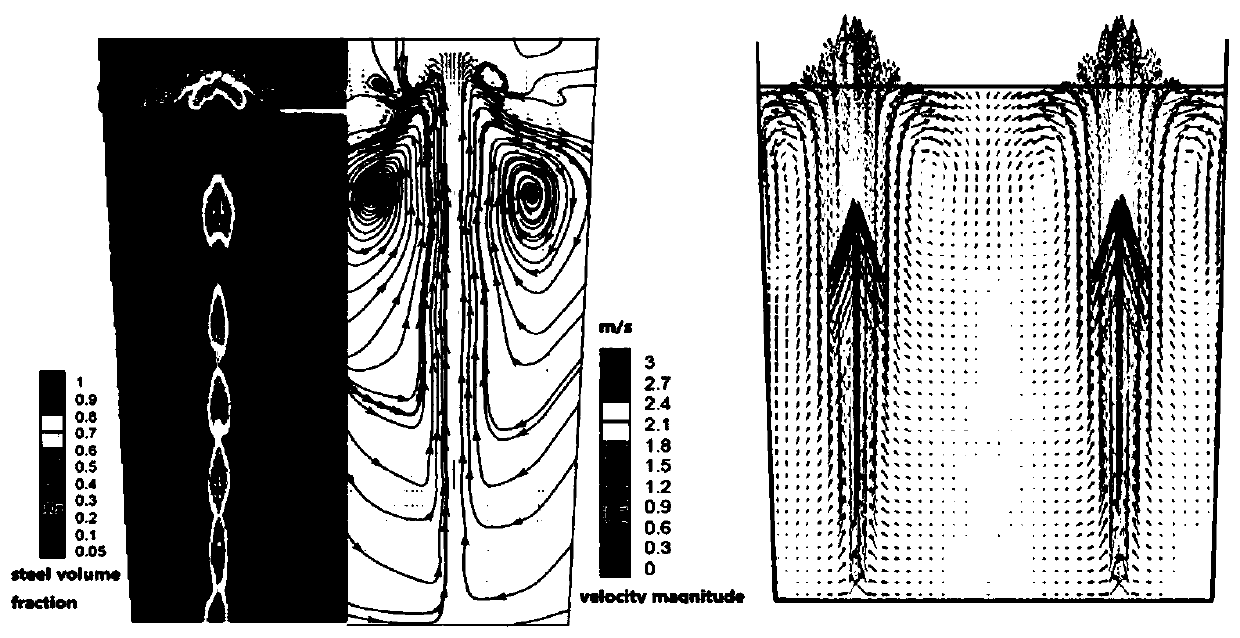

Image

Examples

Embodiment

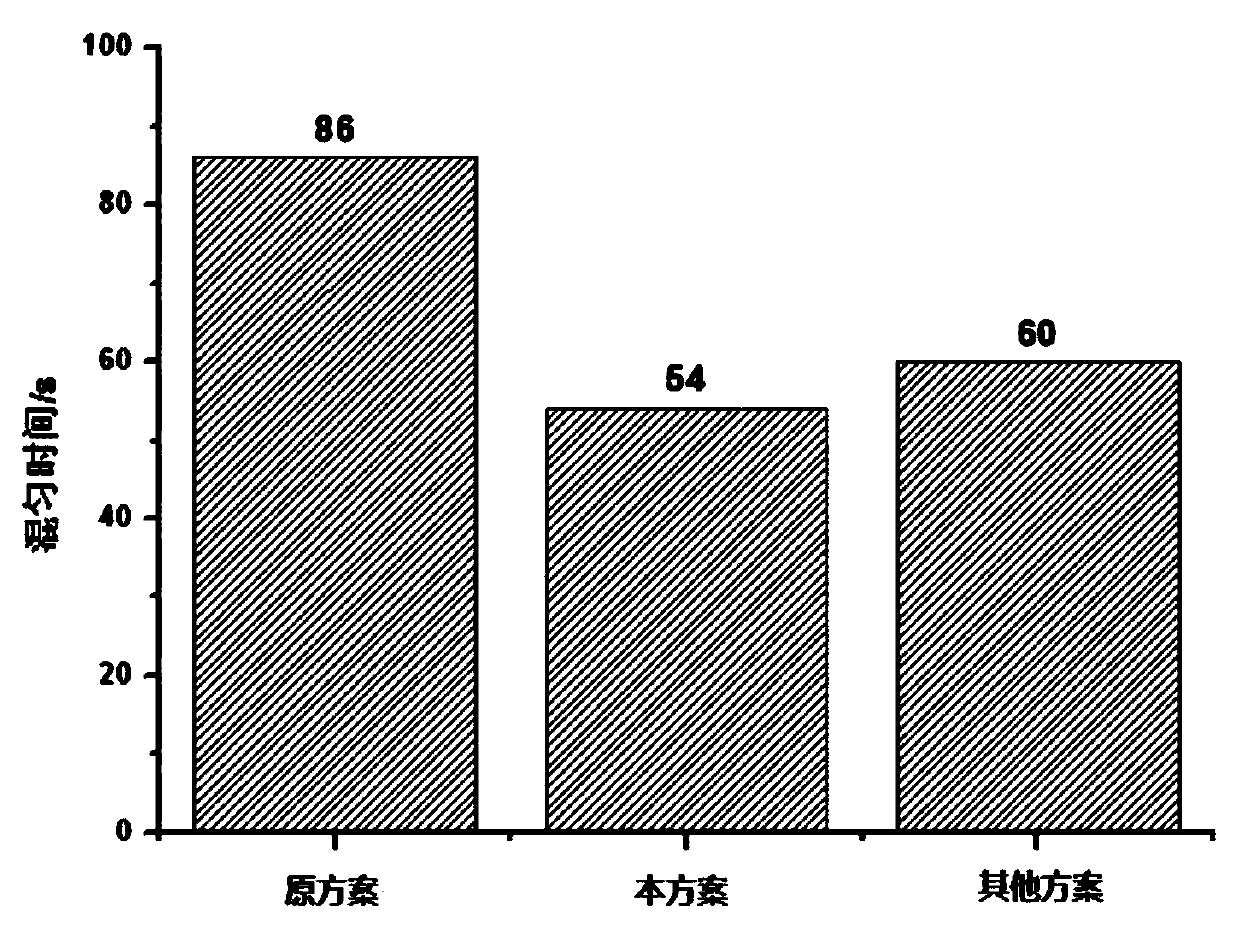

[0022] Select a high-carbon hard wire steel grade for production, and adopt the argon blowing method at the bottom of the ladle. The specific implementation process is as follows:

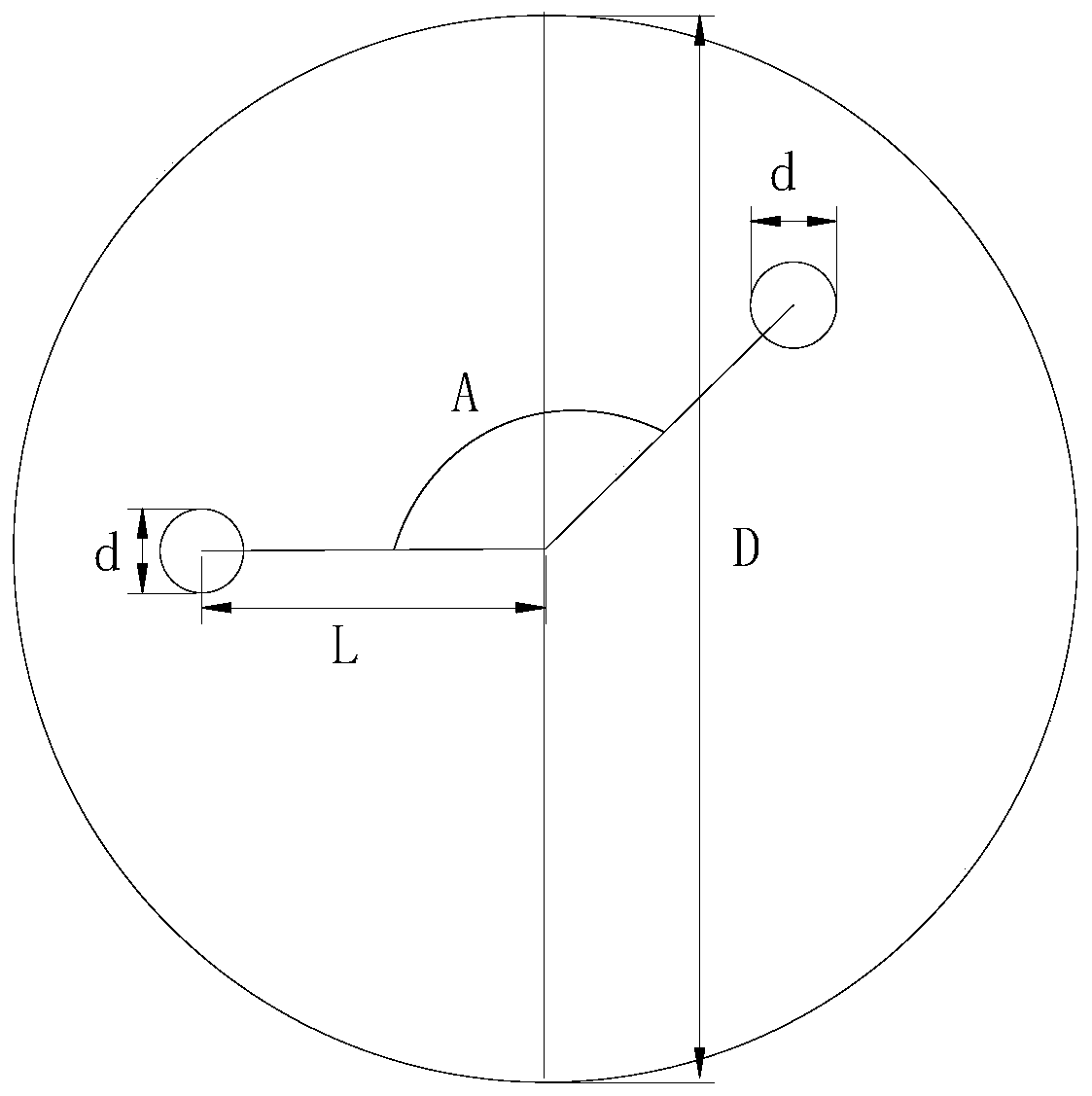

[0023] (1) if figure 1 The argon blowing position at the bottom of the LF refining ladle is designed as shown, where the height-to-diameter ratio of the ladle H / D is 1.19, H is the height of the ladle (mm), D is the diameter of the ladle (mm), the diameter of the venting brick nozzle d and the diameter of the bottom of the ladle D The ratio d / D was 0.04. The angle A between the center position of the two air-permeable bricks at the bottom of the ladle and the center of the ladle bottom is 135°; the distance between the center position of the air-permeable brick and the center of the ladle bottom is L=0.6R, where R is the radius of the bottom of the ladle, and R=1 / 2D;

[0024] (2) Control the argon blowing flow rate Q of a single ventilating brick in stages according to the refining process of sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com