Novel LED packaging structure

A technology of LED packaging and LED chips, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as uneven light spots, low light extraction efficiency, and uneven color temperature, and achieve improved uniformity, light output efficiency, and high color temperature consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further elaborate on the technical solutions of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

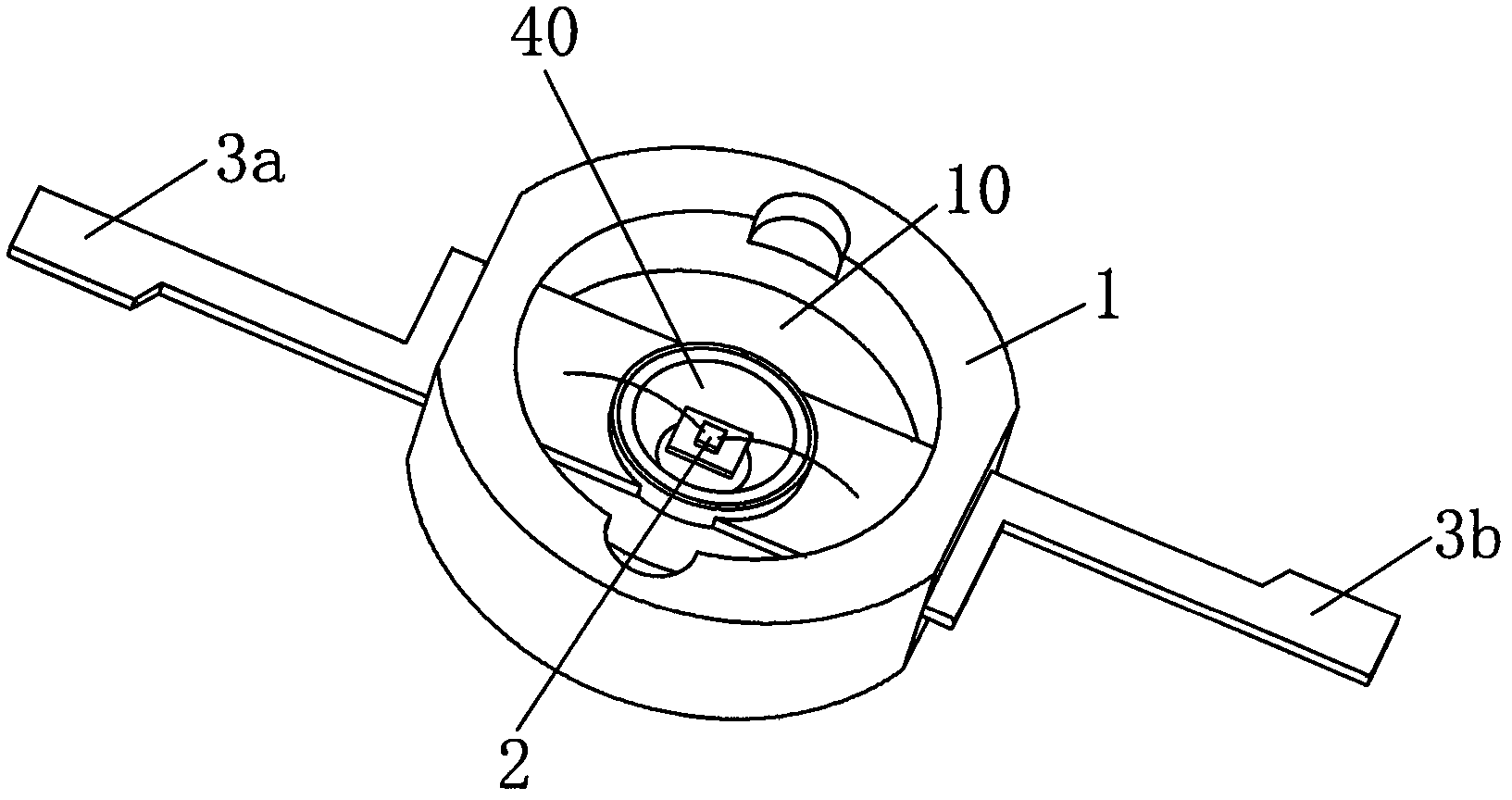

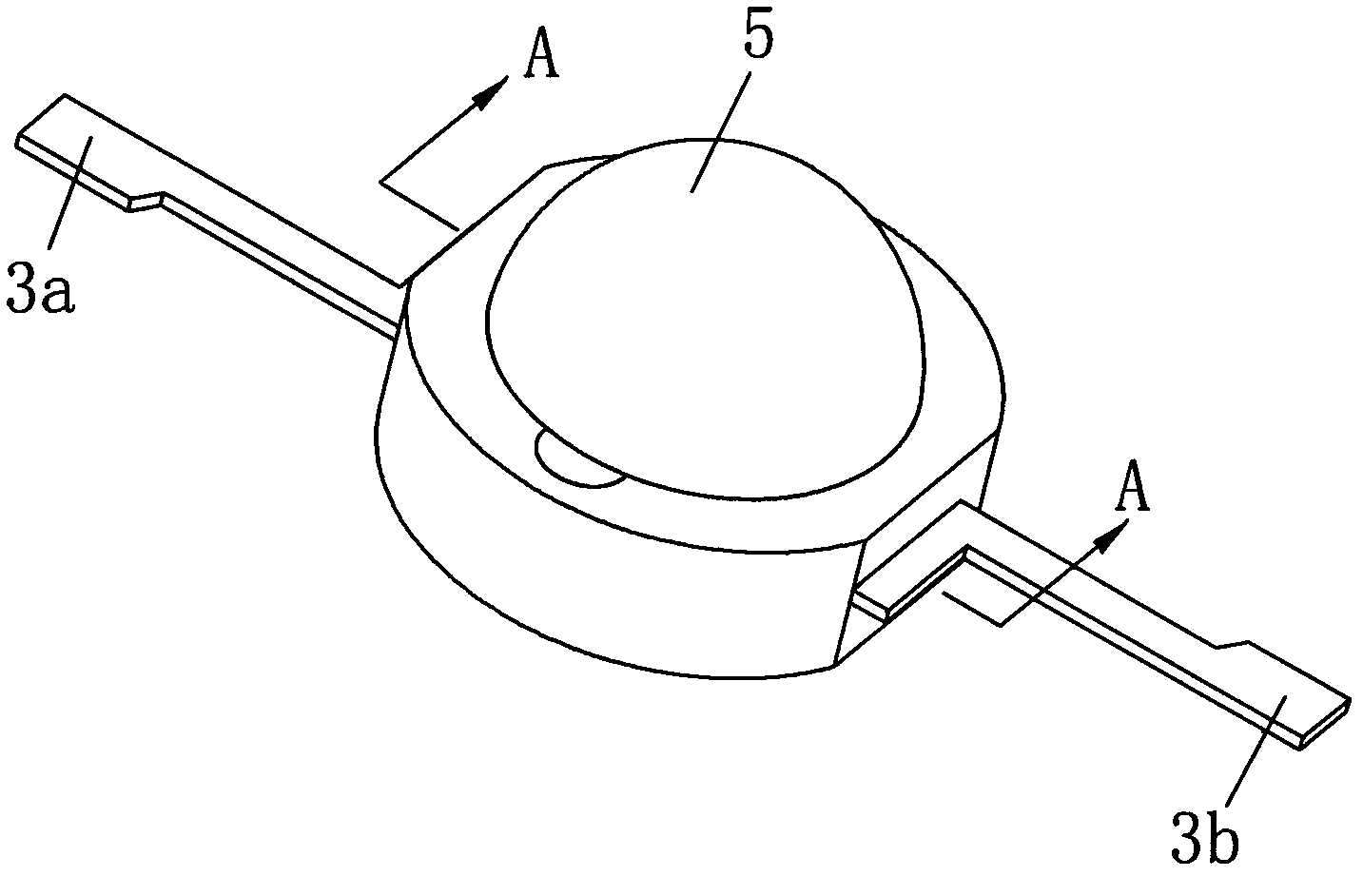

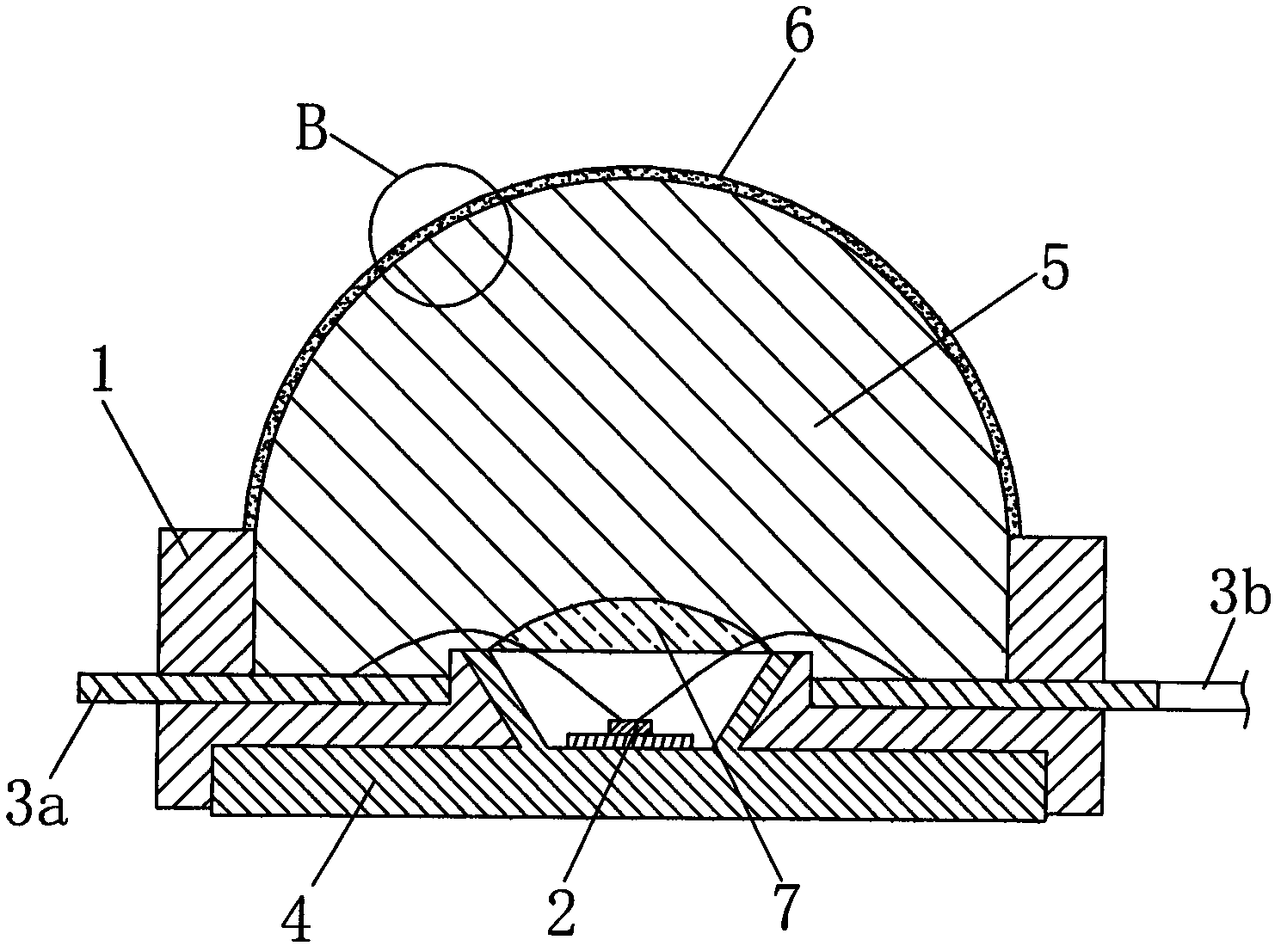

[0022] Such as figure 1 , figure 2 , image 3 As shown, a new LED packaging structure includes a base 1, a cavity 10 formed in the base 1, a heat sink 4 fixed in the cavity 10, a cup and bowl 40 formed on the heat sink 4 and fixed on the The LED chip 2 in the cup bowl 40, a pair of conductive pins 3a, 3b are extended and fixed in the base 1, the LED chip 2 is electrically connected with the conductive pins 3a, 3b, and a lens 5 is formed on the base 1 The LED chip 2 and part of the conductive feet are covered, and a layer of phosphor coating 6 is provided on the outer surface of the lens 5 .

[0023] The LED packaging structure of the present invention breaks the traditional LED packaging mode, and directly transfers the phosphor coating from the original chip surface to the lens surface, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com