Concrete strength rapid determination method

A technology for rapid determination of concrete strength, applied in the direction of measuring devices, preparation of test samples, instruments, etc., can solve problems such as poor prediction accuracy, and achieve the goals of improved accuracy, small average relative error, good correlation and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

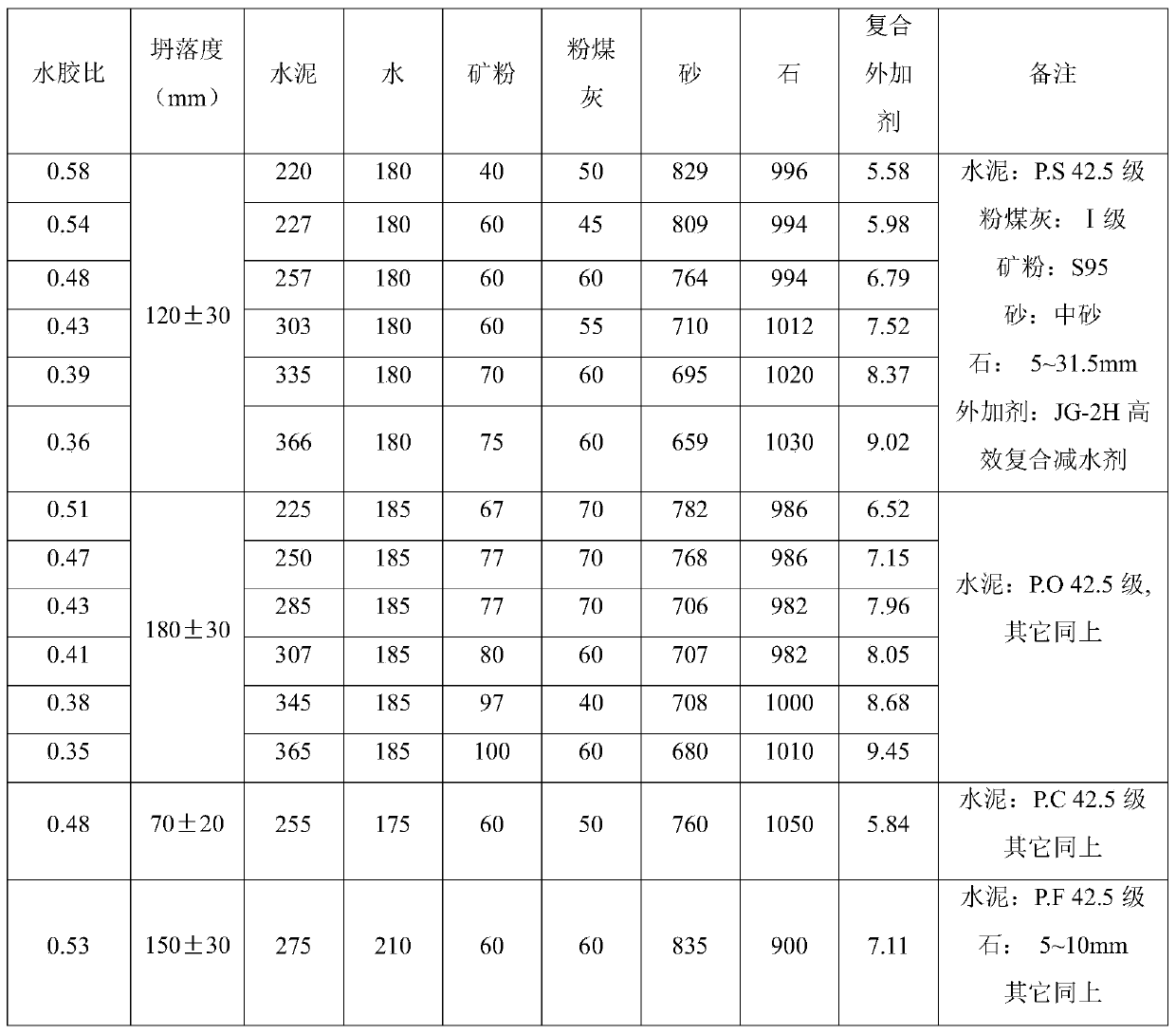

[0048] The concrete mix ratio actually used in the construction is adopted, and the same materials as the concrete on site are used.

[0049] 2. Test piece production

[0050] (1) Make concrete specimens → pre-embed the temperature test element in the center of the concrete specimens → rest the specimens in a room at 20±5°C for 1 / 2 hour after forming and plastering the specimens → put the specimens in a standard curing box for 24 hours → Remove the mold and put it into the accelerated curing box → Increase the temperature of the concrete center to 80°C within 3 / 4 hours → Adjust the water temperature and control the temperature of the concrete center to 80°C through the temperature test element, keep it for 16 hours → Take out the test piece at 20±5 ℃ Indoor cooling for 3 / 4 hours → do a compression test, and measure the accelerated curing strength R16h;

[0051] (2) Each concrete sample should be molded into two groups of specimens to form a pair: accelerated curing specimens ...

Embodiment 1

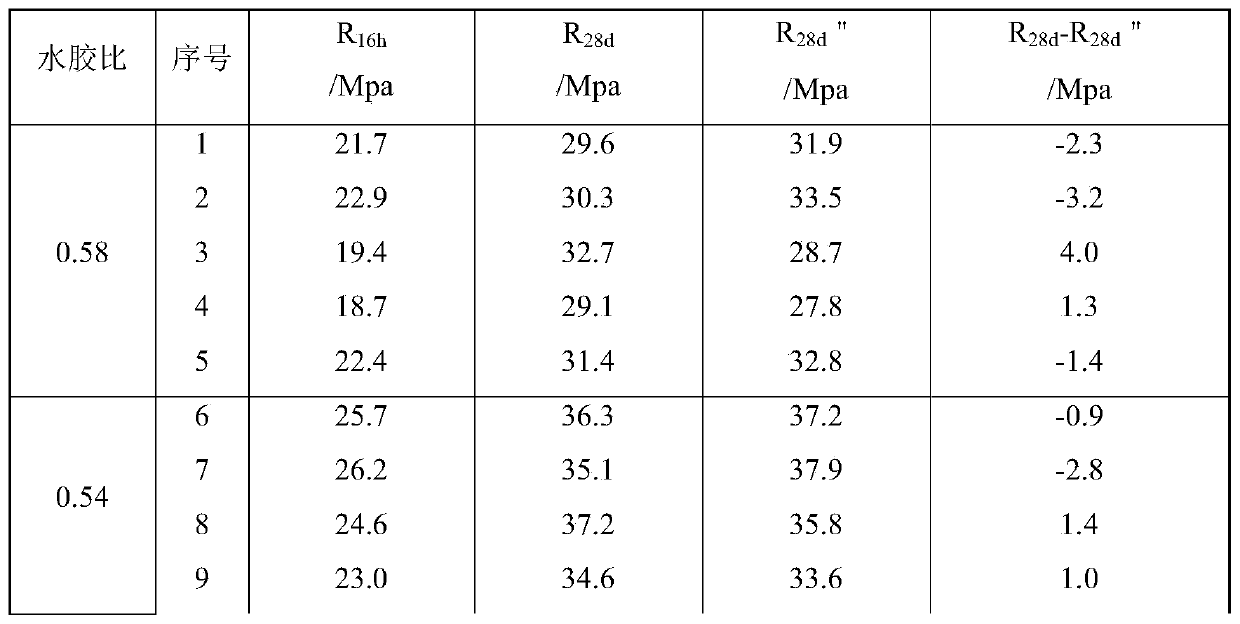

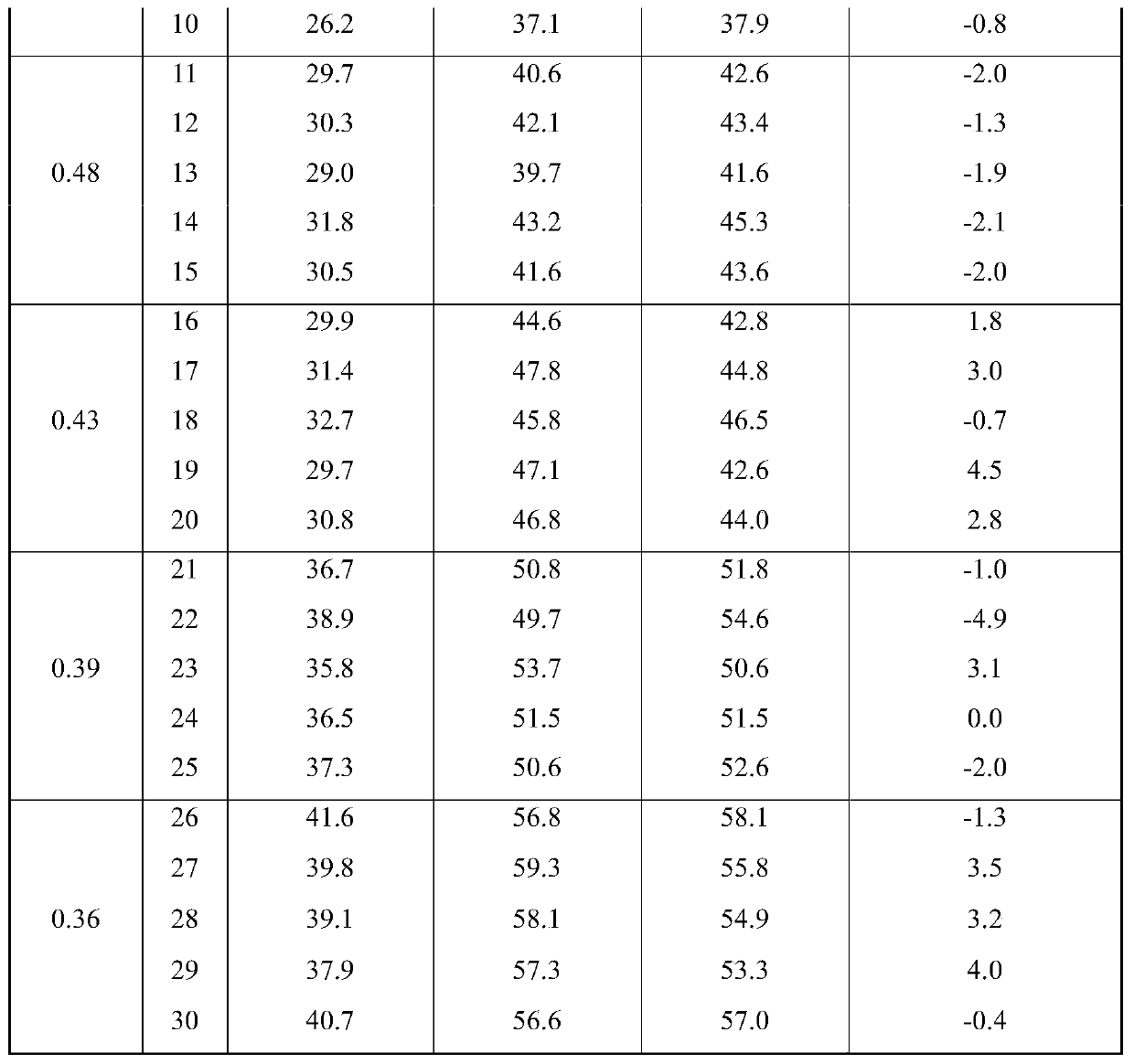

[0062] In this embodiment, the strength of concrete specimens with a water-binder ratio of 0.36 to 0.58 and a slump of 120 ± 30mm is quickly measured and estimated, and the mix ratio of concrete specimen pairs is specifically as follows figure 1 shown. The concrete strength R measured in each test 28d and the corresponding rapid hardening strength of concrete R 16h And the established strength estimation formulas are as follows figure 2 and image 3 shown. Specifically, such as Figure 10 As shown, in this embodiment, the power function type presumes the strength: R 28d "=23.952R 16h 0.2344 , R 2 =0.8367, S=2.524, C V = 5.75%.

Embodiment 2

[0064] In this embodiment, the strength of concrete specimens with a water-binder ratio of 0.35 to 0.51 and a slump of 180±30mm is quickly measured and estimated, and the mix ratio of concrete specimen pairs is as follows: figure 1 shown. The concrete strength R measured in each test 28d and the corresponding rapid hardening strength of concrete R 16h And the established strength estimation formulas are as follows Figure 4 and Figure 5 shown. Specifically, in this embodiment, the power function type infers the strength: R 28d "=24.228R 16h 0.2393 , R 2 =0.8646, S=2.662, C V = 5.92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com