A kind of preparation method of potassium metavanadate dispersion coating nickel-cobalt-manganese ternary positive electrode material

A technology of potassium metavanadate and positive electrode materials, which is applied in the direction of electrical components, battery electrodes, structural parts, etc., can solve the problems of low electrochemical performance stability, unstable performance improvement, and slow solid phase diffusion speed, etc., to achieve improved The effect of electrochemical performance, shortening the production cycle, and improving the stability of the surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

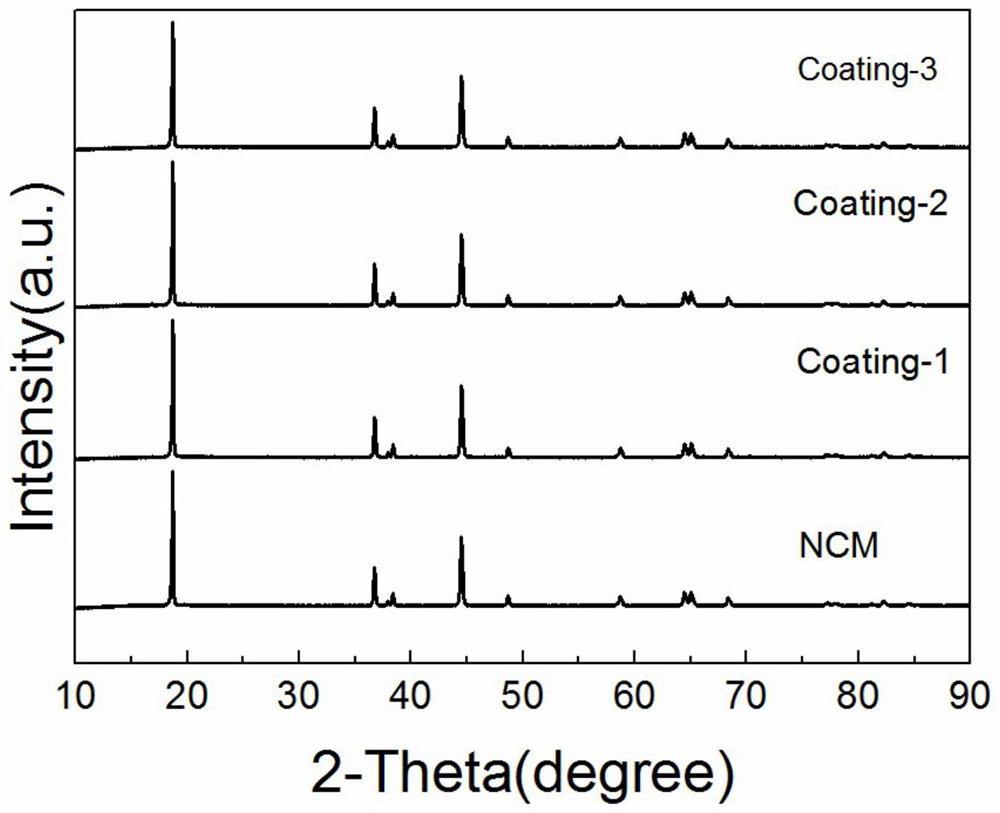

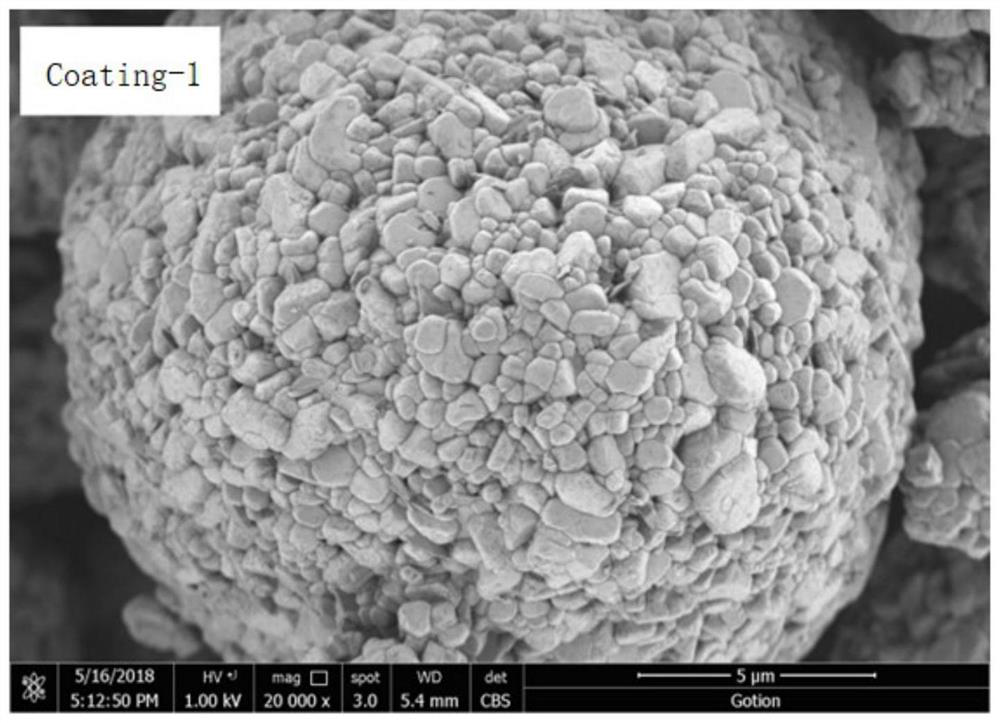

[0031] A method for preparing a nickel-cobalt-manganese ternary cathode material dispersed and coated with potassium metavanadate, specifically comprising the following steps:

[0032] (1), firstly nickel sulfate, cobalt sulfate, manganese sulfate solution are mixed and then added in the sodium hydroxide solution containing ammonia, carry out co-precipitation reaction and obtain ternary composite precursor (Ni 0.65 co 0.15 mn 0.20 )(OH) 2 ; Wherein, the control pH of the co-precipitation reaction is 11, the temperature is 60°C, the stirring speed is 500r / min, and the aging time is 3h;

[0033] (2), the ternary composite precursor (Ni 0.65 co 0.15 mn 0.20 )(OH) 2 Wash, beat and filter with deionized water at 60°C to control Na + The mass fraction is ≤0.02%, and slurry A is obtained;

[0034] (3), lithium hydroxide and potassium metavanadate are according to molar ratio (Ni 0.65 co 0.15 mn 0.20 )(OH) 2 : Li:KVO3=1:1.06:0.01 proportioning, then join in the slurry A th...

Embodiment 2

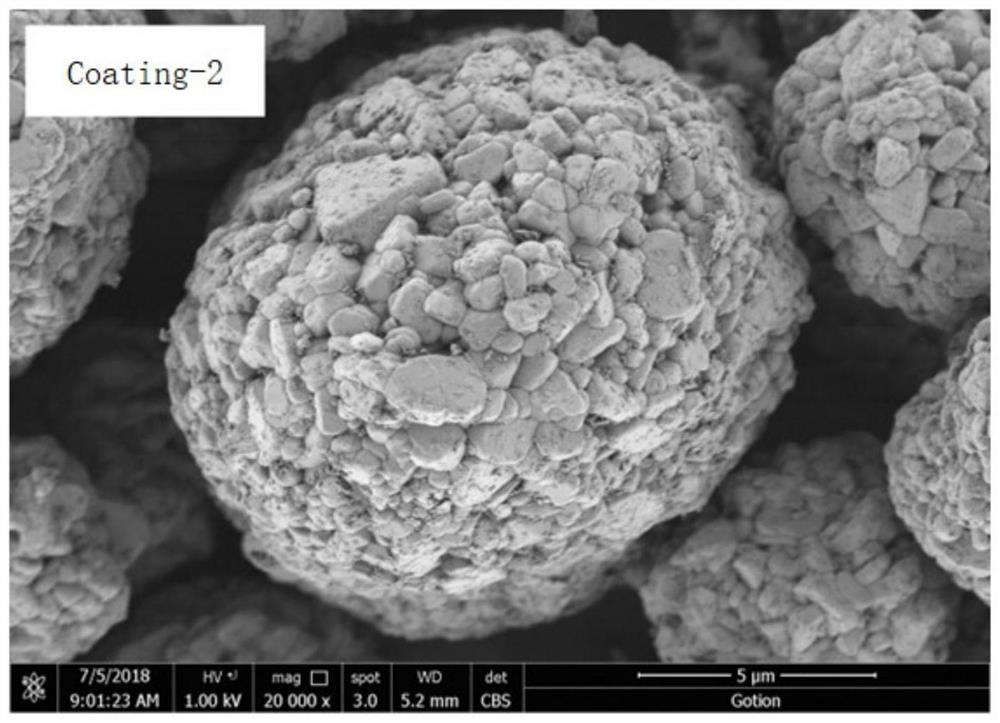

[0037] A method for preparing a nickel-cobalt-manganese ternary cathode material dispersed and coated with potassium metavanadate, specifically comprising the following steps:

[0038](1), firstly nickel sulfate, cobalt sulfate, manganese sulfate solution are mixed and then added in the sodium hydroxide solution containing ammonia, carry out co-precipitation reaction and obtain ternary composite precursor (Ni 0.65 co 0.15 mn 0.20 )(OH) 2 ; Among them, the control pH of the coprecipitation reaction is 11.5, the temperature is 60°C, the stirring speed is 600r / min, and the aging time is 3h;

[0039] (2), the ternary composite precursor (Ni 0.65 co 0.15 mn 0.20 )(OH) 2 Wash, beat and filter with deionized water at 60°C to control Na + The mass fraction is ≤0.02%, and slurry A is obtained;

[0040] (3), lithium hydroxide and potassium metavanadate are according to molar ratio (Ni 0.65 co 0.15 mn 0.20 )(OH) 2 : Li:KVO3=1:1.06:0.005 proportioning, then join in the slurry ...

Embodiment 3

[0043] A method for preparing a nickel-cobalt-manganese ternary cathode material dispersed and coated with potassium metavanadate, specifically comprising the following steps:

[0044] (1), firstly nickel sulfate, cobalt sulfate, manganese sulfate solution are mixed and then added in the sodium hydroxide solution containing ammonia, carry out co-precipitation reaction and obtain ternary composite precursor (Ni 0.65 co 0.15 mn 0.20 )(OH) 2 ; Wherein, the control pH of the co-precipitation reaction is 11, the temperature is 55°C, the stirring speed is 500r / min, and the aging time is 3h;

[0045] (2), the ternary composite precursor (Ni 0.65 co 0.15 mn 0.20 )(OH) 2 Wash, beat and filter with deionized water at 60°C to control Na + The mass fraction is ≤0.02%, and slurry A is obtained;

[0046] (3), lithium carbonate and potassium metavanadate according to molar ratio (Ni 0.65 co 0.15 mn 0.20 )(OH) 2 :Li:KVO 3 =1:1.06:0.003 proportioning, then join in the slurry A tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com