Positive electrode material as well as preparation method and application thereof

A technology of positive electrode materials and additives, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of low post-treatment temperature and unsatisfactory coating effect, reduce oxygen release, improve cycle stability, and reduce interface The effect of impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

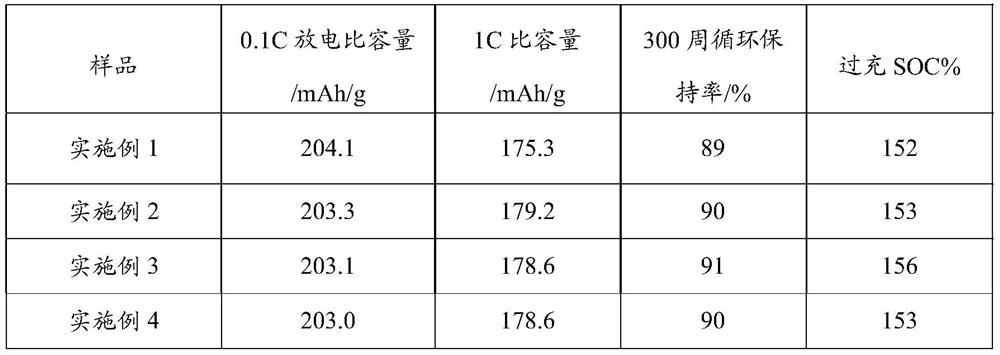

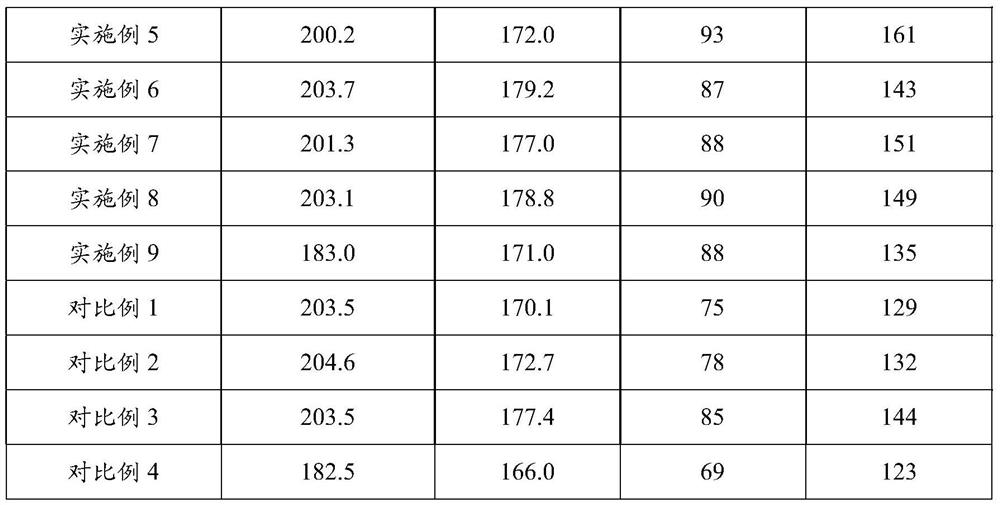

Examples

preparation example Construction

[0050] The present invention also provides a method for preparing the above positive electrode material, comprising the following steps: S1) mixing the positive electrode material matrix, additive A and additive B to obtain a mixture; S2) calcining the mixture to obtain a positive electrode material.

[0051] Among them, the present invention has no special restrictions on the sources of all raw materials, which can be commercially available or homemade; the types and proportions of the positive electrode material matrix, additive A and additive B are the same as those described above, and will not be repeated here; The average particle size of the positive electrode material matrix is preferably 30 to 50000 nm, more preferably 0.1 to 50 μm, and further preferably 0.15 to 20 μm; 22 μm; the average particle size of the additive A is preferably 5-30000 nm; in the embodiments provided by the present invention, the average particle size of the additive A is specifically 1100 nm, ...

Embodiment 1

[0059] The positive electrode material matrix adopts a sample (NCM811) of nickel cobalt lithium manganate (nickel: cobalt: manganese = 8: 1: 1) with D50 of about 12 μm;

[0060] Lithium difluorophosphate (average particle size: 1100nm), lithium phosphate (average particle size: 130nm), and NCM811 were uniformly mixed in a mixer according to a mass ratio of 0.5:0.2:100, and then heat-treated at 350°C for 12h in an oxygen atmosphere. A positive electrode material A1 was obtained.

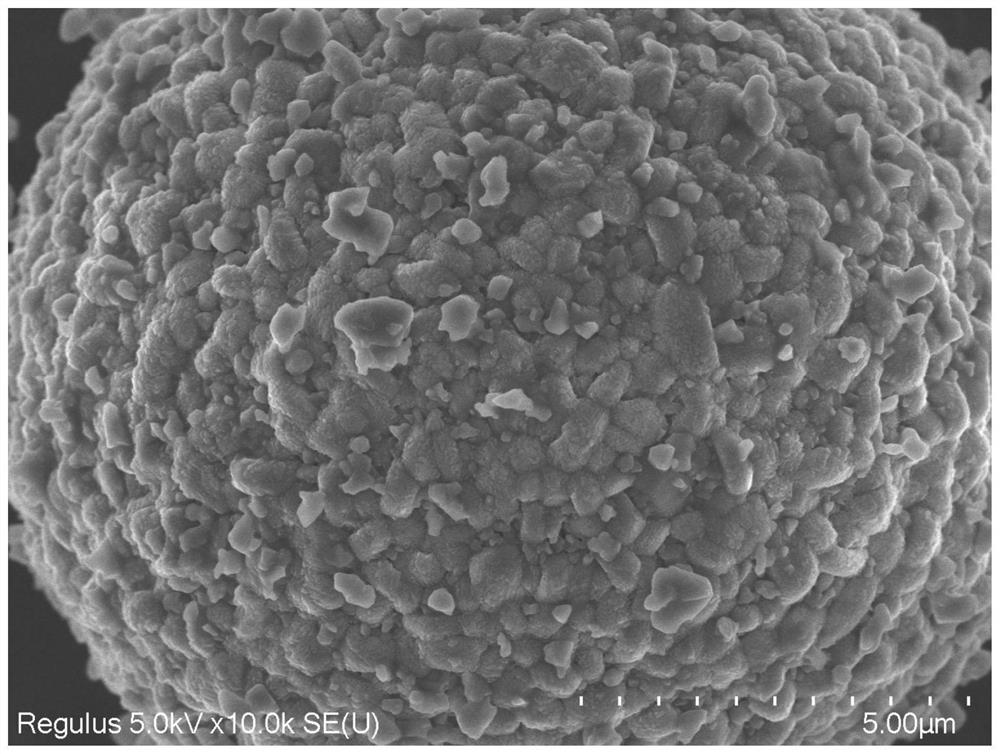

[0061] The positive electrode material obtained in Example 1 was analyzed using a scanning electron microscope, and its scanning electron microscope photo was obtained as follows: figure 1 shown.

Embodiment 2

[0063] The cathode material matrix adopts NCM811 sample with D50 of about 12μm;

[0064] Lithium difluorophosphate (average particle size: 1100 nm), lithium lanthanum zirconate (average particle size: 200 nm), and NCM811 were added to 100 parts of ethanol in a ratio of 0.5:0.9:100 by mass, stirred evenly, and dried at 70°C , the dried material was heat-treated at 400° C. in an oxygen atmosphere for 5 h to obtain a positive electrode material A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com