A kind of high-nickel layered composite material and lithium-ion battery cathode material prepared therefrom

A layered composite material, lithium-ion battery technology, applied in the direction of battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of unsatisfactory chemical properties and stability, and achieve suitable for large-scale production, environmental friendliness, and improved cycle performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-15

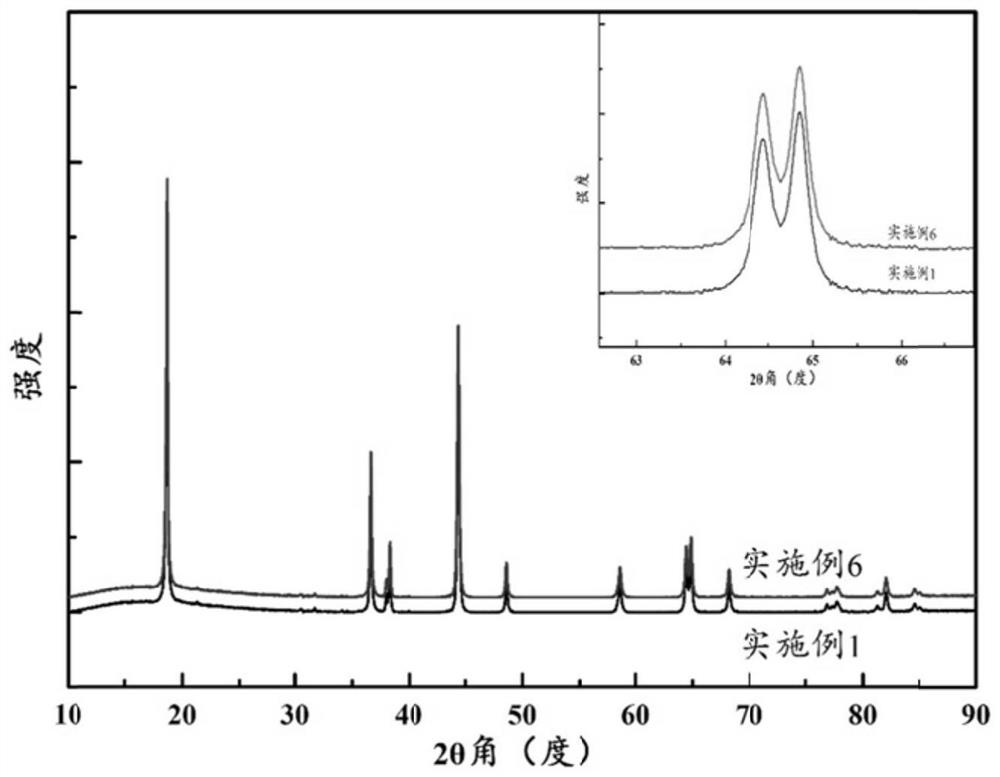

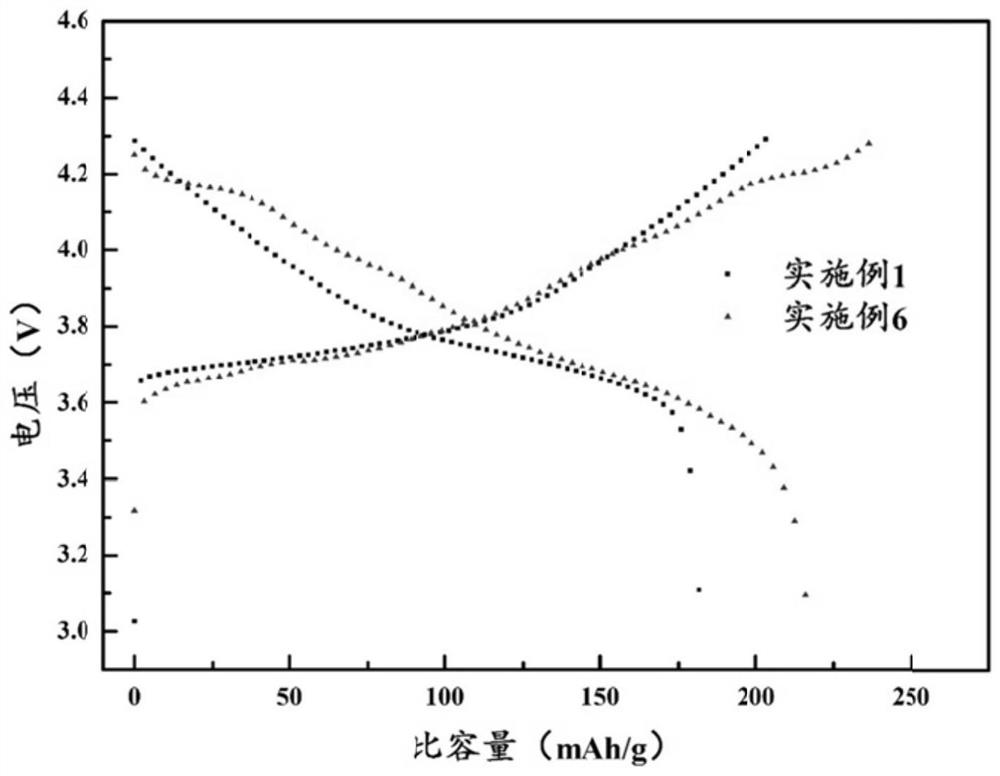

[0055] The preparation of high-nickel layered composites with selected compositions was carried out according to the chemical formula listed in Table 1 below.

[0056] Prepare NiSO according to the ratio of Ni and Mn in the chemical formula listed in Table 1 4 , MnSO 4 Mix the solution to control the total concentration of metal cations to 2.0mol / L.

[0057] Preparation of NaOH and NH 3 ·H 2 O mixed solution, control NaOH concentration to 3.0mol / L, NH 3 ·H 2 O concentration is 0.30mol / L.

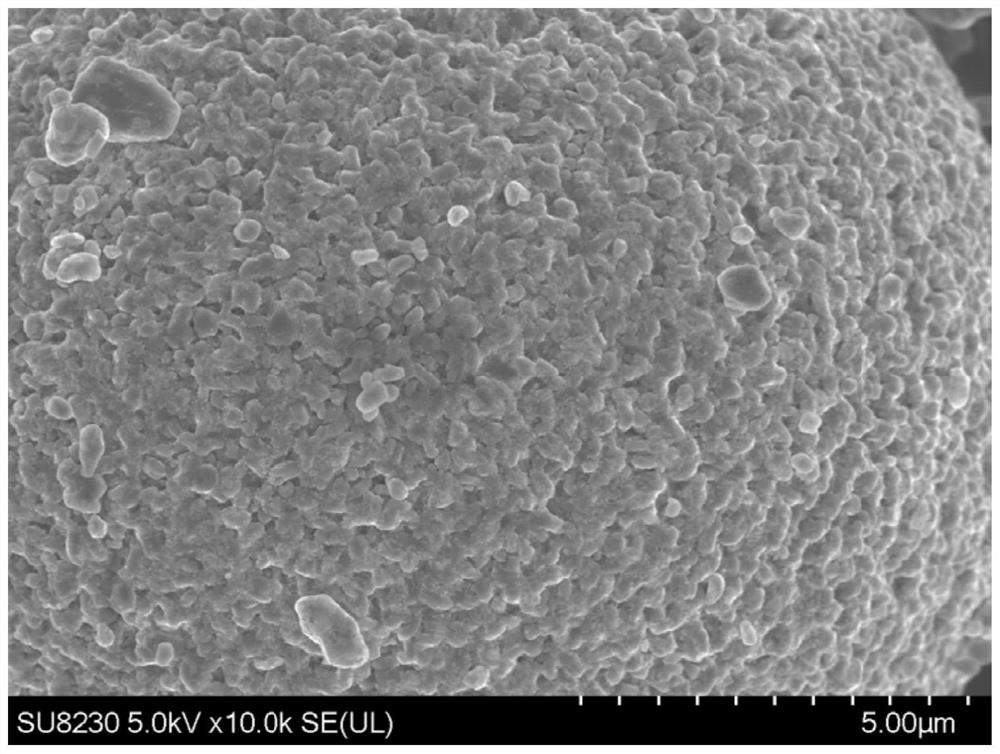

[0058] Use a peristaltic pump to add the above two parts of the solution dropwise into the reaction vessel, control the volume ratio of the above sulfate mixed solution to the lye to 1:2.1, and control the pH value at about 10, and heat it in a water bath at 50°C for 24 hours; After the reaction is completed, after suction filtration, washing, and drying in a vacuum oven at 120°C for 12 hours, the desired M(OH) 2 Precursors (M=Ni, Mn).

[0059] Weigh LiOH, ZrO according to the ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com