Lithium cobalt oxide positive electrode material with stable surface structure and preparation method of lithium cobalt oxide positive electrode material

A surface structure and positive electrode material technology, applied in the direction of structural parts, chemical instruments and methods, cobalt compounds, etc., can solve the problems of unstable surface structure, unfavorable lithium ion extraction and intercalation, etc., to achieve enhanced surface structure stability, good ratio Effects of capacity, cycle capacity retention, and good electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

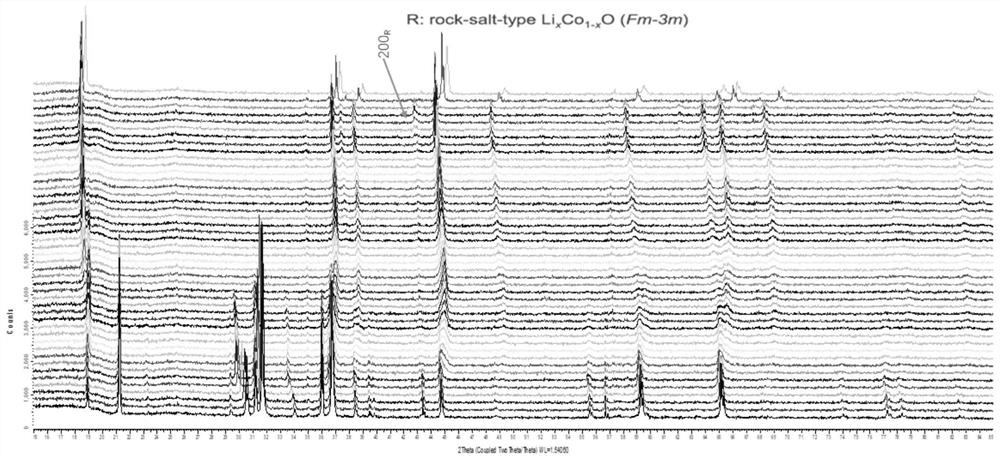

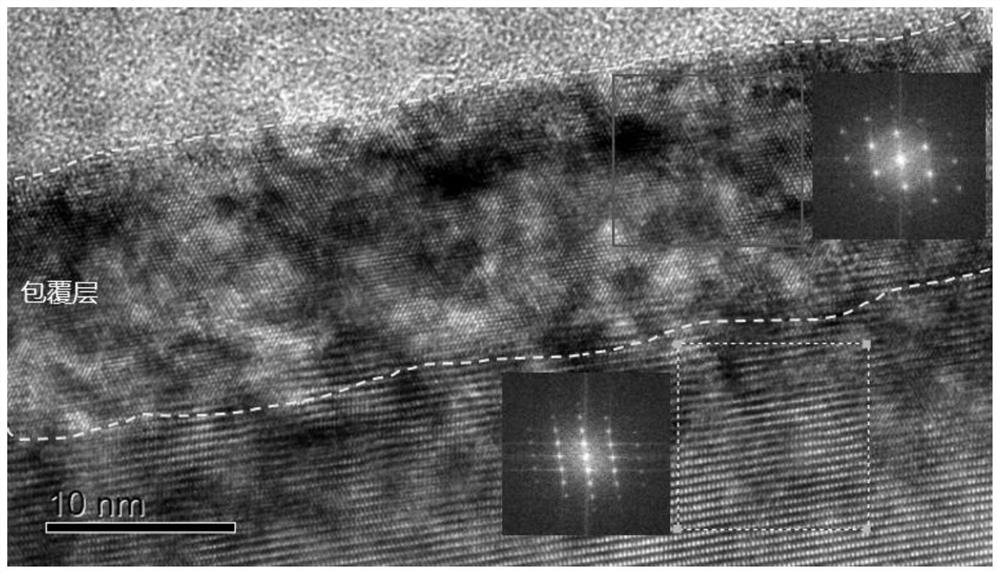

[0028] Example 1: In situ preparation of coated Li 0.4 Co 0.33 Ti 0.15 Mg 0.12 Co 1.2 Al 0.8 O 4 LiCo 0.982 Al 0.018 O 2

[0029] According to the general formula Li 1.065 Co 0.982 Al 0.018 O 2 Weigh the weight of each material, mix it evenly, and put it into a gas-permeable sintering furnace for sintering treatment. Among them, the lithium-containing precursor is lithium carbonate, the D50 of the cobalt-containing precursor is 16 μm, the cobalt-containing precursor has a core-shell structure, and the shell layer Co 0.73 Ti 0.15 Mg 0.12 Co 1.2 Al 0.8 O 4 , the kernel CoO [Co 0.991 Al 0.009 ] 2 O 3 , the lithium-containing precursor and the cobalt-containing precursor are sintered together, the sintering temperature is 1040 ° C, when the temperature rises from room temperature to 1040 ° C, air is introduced, and the gas flow rate is 70 ml / min. The holding time at 1040 °C is 600 minutes, and the vacuum is drawn during the holding period, and the pressure ...

Embodiment 2

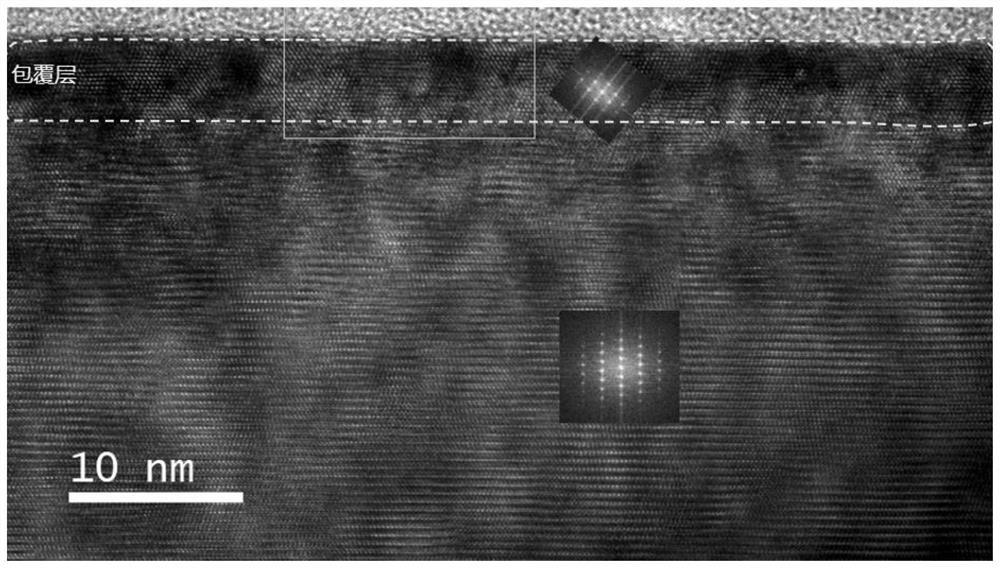

[0030] Example 2: In situ preparation of coated Li 0.4 Co 0.33 Ti 0.15 Mg 0.12 Co 1.2 Al 0.8 O 4 LiCo 0.982 Al 0.018 O 2

[0031] According to the general formula Li 1.065 Co 0.982 Al 0.018 O 2 Weigh the weight of each material, mix it evenly, and put it into a gas-permeable sintering furnace for sintering treatment. Among them, the lithium-containing precursor is lithium carbonate, the D50 of the cobalt-containing precursor is 16 μm, the cobalt-containing precursor has a core-shell structure, and the shell layer Co 0.73 Ti 0.15 Mg 0.12 Co 1.2 Al 0.8 O 4 , the kernel CoO [Co 0.991 Al 0.009 ] 2 O 3 , the lithium-containing precursor and the cobalt-containing precursor are sintered together, the sintering temperature is 850 °C, and when the temperature rises from room temperature to 850 °C, air is introduced, and the gas flow rate is 70 ml / min. The holding time at 850 °C is 900 minutes, and the vacuum is drawn during the holding period, and the pressure i...

Embodiment 3

[0032] Example 3: In situ preparation of coated Li 0.4 Co 0.33 Ti 0.15 Mg 0.12 Co 1.2 Al 0.8 O 4 LiCo 0.982 Al 0.018 O 2

[0033] According to the general formula Li 1.065 Co 0.982 Al 0.018 O 2 Weigh the weight of each material, mix it evenly, and put it into a gas-permeable sintering furnace for sintering treatment. Among them, the lithium-containing precursor is lithium carbonate, the D50 of the cobalt-containing precursor is 16 μm, the cobalt-containing precursor has a core-shell structure, and the shell layer Co 0.73 Ti 0.15 Mg 0.12 Co 1.2 Al 0.8 O 4 , the kernel CoO [Co 0.991 Al 0.009 ] 2 O 3 , the lithium-containing precursor and the cobalt-containing precursor are sintered together, the sintering temperature is 1040 ° C, and when the temperature rises from room temperature to 1200 ° C, air is introduced, and the gas flow rate is 70 ml / min. The holding time at 1200 °C is 0 minutes, and the vacuum is drawn during the holding period, and the pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com