A shoe sole noise testing machine and testing method

A testing machine and noise technology, applied to foot or shoe last measuring devices, footwear, measuring devices, etc., can solve the problems of long testing time and general testing effect, and achieve the effect of fast testing, reliable results and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

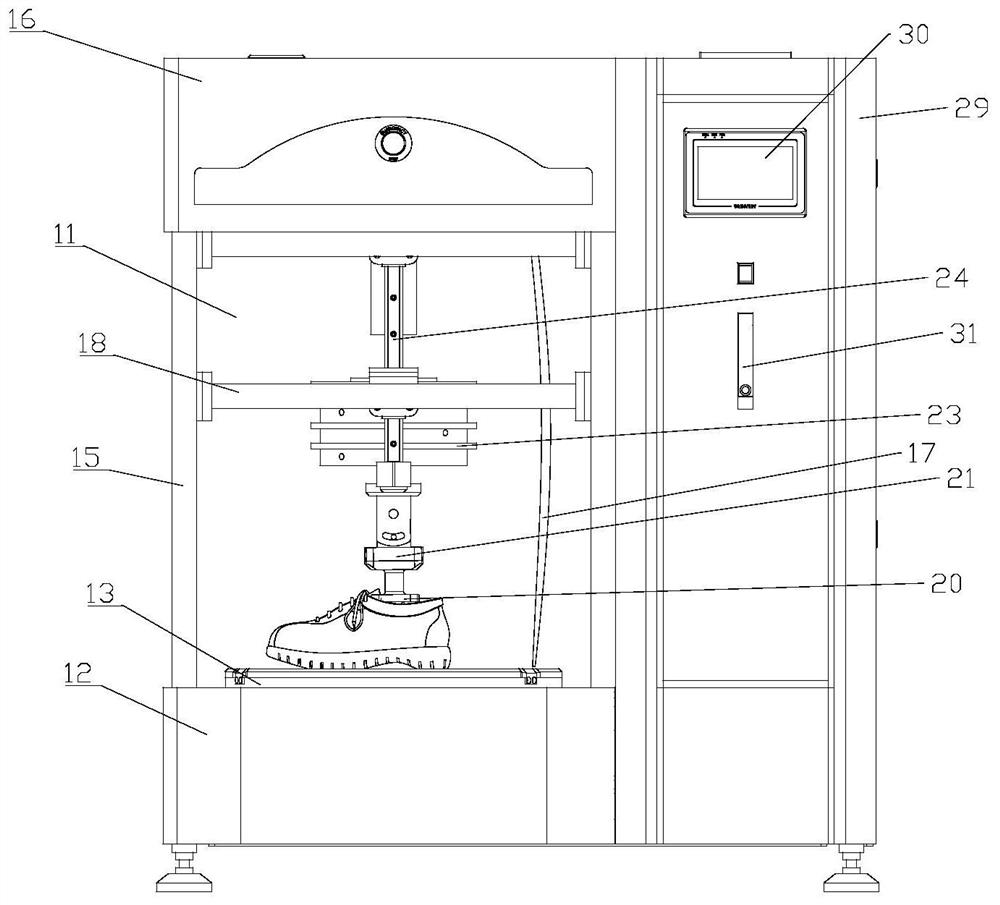

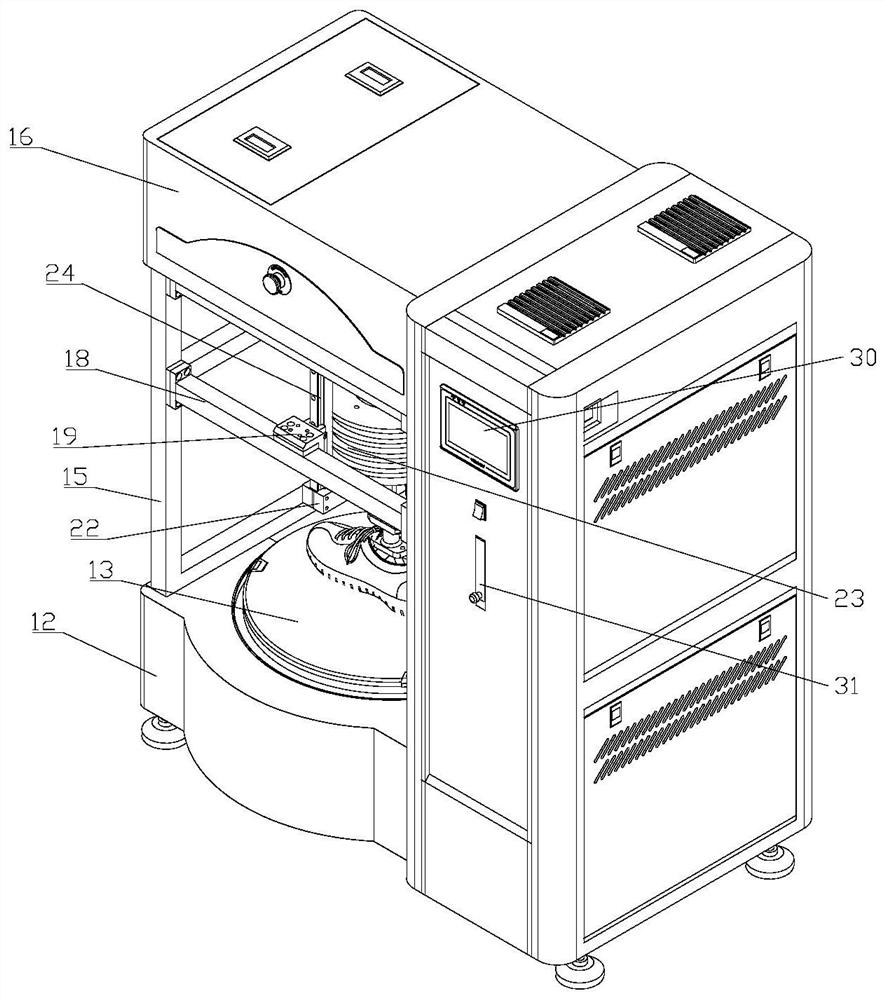

[0021] Please refer to accompanying drawing, present embodiment is a kind of sole noise testing machine, is used for testing finished shoe sole noise, and it comprises test case 11, and test case 11 bottom is provided with test base 12, and test base 12 middle top is provided with friction turntable 13 , the test base 12 is provided with a rotating device 14, the friction turntable 13 is connected to the rotating device 14, the test base 12 is also provided with a support frame 15, the top of the test case 11 is provided with a liquid storage tank 16, and the liquid storage tank 16 is located on the support frame 15 The upper end and the bottom of the liquid storage tank 16 are provided with a liquid pipe 17, and the end of the liquid pipe 17 away from the liquid storage tank 16 is arranged on the friction turntable 13, the support frame 15 is provided with a middle bracket 18, and a guide slider is installed on the middle bracket 18 19. There is a test fixture in the test box ...

Embodiment 2

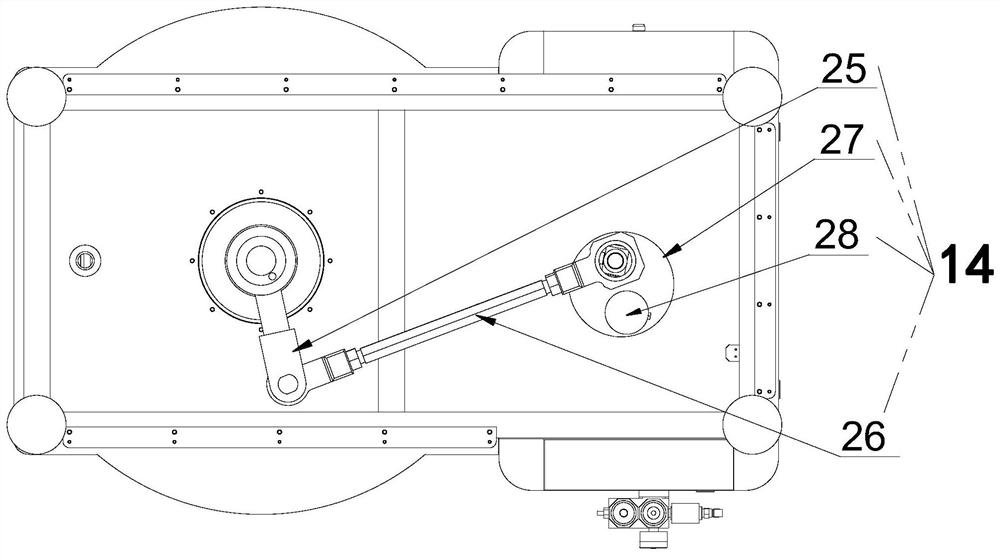

[0026] In this embodiment, on the basis of Embodiment 1, an angle adjustment plate 35 is provided at the end of the connecting rod 26 away from the transmission arm 25, and an eccentric wheel 27 is arranged in the middle of the angle adjustment plate 35, and the eccentric wheel 27 is connected to the input end of the motor 28, and the adjustment The angle plate 35 is provided with a chute, the end of the connecting rod 26 cooperates with the chute, the end of the connecting rod 26 is equipped with a moving rod 34, the moving rod 34 is connected to the eccentric wheel 27, and one end of the angle adjusting plate 35 is connected to the test base 12 in rotation , can rotate the angle adjustment plate 35, change the inclination angle of the angle adjustment plate 35, move the connecting rod 26, change the distance between the connecting rod 26 and the input end of the motor, when in use, the motor 28 drives the eccentric wheel 27 to rotate, and the eccentric wheel 27 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com